What Is Takt Time and How Do You Use It? (Ultimate Guide)

Udn Webber

Managing Editor

Want to learn about takt time?

Takt time is an essential metric used in the manufacturing process that functions as the heartbeat of your production line.

It lets you manage every business operation efficiently and without waste. Toyota used and perfected takt time in its famous Just-in-Time manufacturing system. And because of this, you can see a Toyota on every street today!

In this article, we’ll explain what is takt time, its benefits, and how it’s used in Lean project management .

Let’s get started.

What is Takt Time?

In the manufacturing process, takt time is the rate at which you need to finish making a product to meet customer demand.

For example: If the takt time of your company’s production line is two minutes, it means that the final product should be completed in two minutes if you are to meet your customer demand.

Just imagine the assembly line , with each product moving from one station to the next, without missing a beat.

Rhythmic, isn’t it?

That’s why it’s no coincidence that that takt time is named after ‘Takt’: a German term for the baton used by an orchestra conductor to regulate the tempo of the song.

Similar to how a conductor uses their baton to manage the pace of the orchestra, using takt time helps you regulate the speed of the production line. This way, you can maintain a continuous flow of your products without wasting any raw material.

How Do You Calculate Takt Time?

At first glance, measuring takt time seems like a complicated process, but the calculation is actually quite simple.

All you need to do is divide the available production time by the customer demand.

Here’s what it looks like as a formula:

Takt time = available production time/customer demand

Here’s a closer look at the variables involved:

A. Available production time

It’s the amount of time your Lean manufacturing team and equipment have to be actively involved in the production process.

Let’s take a field trip to the Duff Brewery to understand how it works.

The beer bottling plant has a bottling machine that’s used for 9 hours everyday.

That’s around (9×60=) 540 minutes of work a day, right?

Nope.

You’ll have to account for the time your machine will not be running and under supervision, which includes maintenance breaks, shift changes, and lunch breaks.

If a lunch break is around 1 hour and 30 minutes each morning is spent on maintenance and warming up, that means the available production time for the plant’s machine is (540 – 90) = 450 minutes.

B. Customer demand

It’s the number of products an average customer needs every day. Let’s assume that the customer is Moe.

The daily demand of Moe’s Tavern is around 80 cases of beer (considering Barney is his star customer, this comes as no surprise!)

C. Takt time

Now here’s the final calculation for the takt time:

Takt time = Available production time (450 minutes) / Customer demand (80)

Which equates to 337.5 seconds.

That means a case of beer needs to be produced every 5 minutes and 37.5 seconds; otherwise, you won’t be able to meet Moe’s demands.

And trust us, you wouldn’t want to see him angry!

What Is The Purpose Of Takt Time?

Takt time isn’t just used to plan the length of each production cycle. The takt time calculation can be used to predict future production problems and identify a potential bottleneck.

Here are what you can do with takt time:

Let’s take a closer look at these applications:

1. Determine production capacity

Let’s face it, most people want to take up additional work to rake in the big bucks.

However, increasing production beyond your team’s limits will cause two problems:

By knowing the maximum production capacity, you can set realistic expectations for your manufacturing team.

How do you do that?

Maximum Capacity = Total Available Production time / Takt Time

Sticking to the previous example, if the machine runs for 5 days a week, the operation time is 37.5 hours a week. Now, you factor in that it takes around 6 minutes for a six-pack to be manufactured at the assembly line at the plant.

So what’s the maximum amount of Duff Lite packs that can be produced in a week?

Don’t worry; we’ve done the math for you.

37.5/0.1 hours = roughly 375 packs.

That’s a lot of beer!

If the customer demand is anywhere beyond the limit, you’ll need to inform them that their order will be delivered with the next week’s batch.

2. Estimate production time

Now let’s take a look at another example.

Let’s suppose you work in the HR department at Duff HQ.

You need to hire a huge batch of employees quickly, and you’ve received 40 applications.

First, you need to figure out how long it takes to work on one form.

How do you do that?

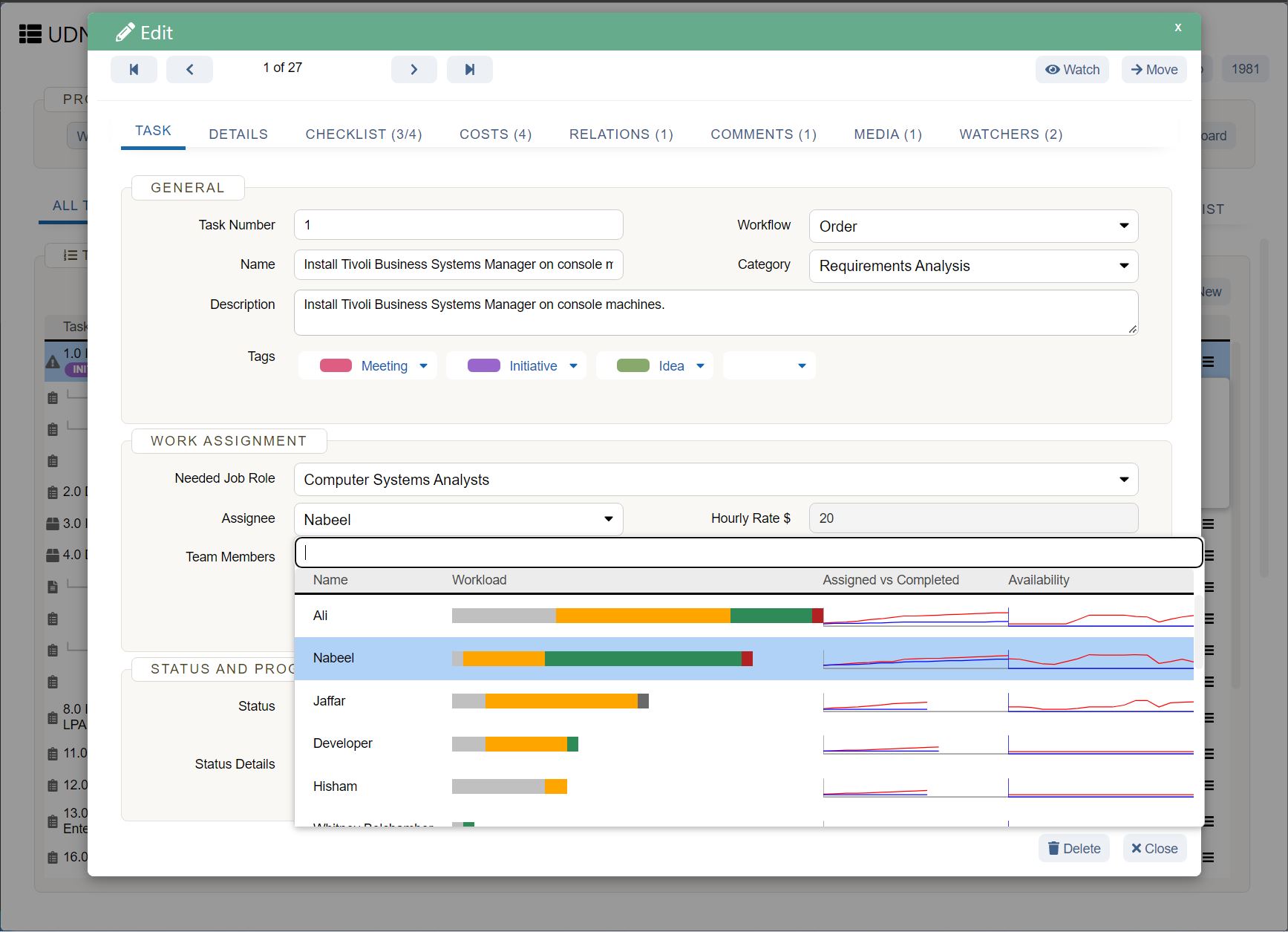

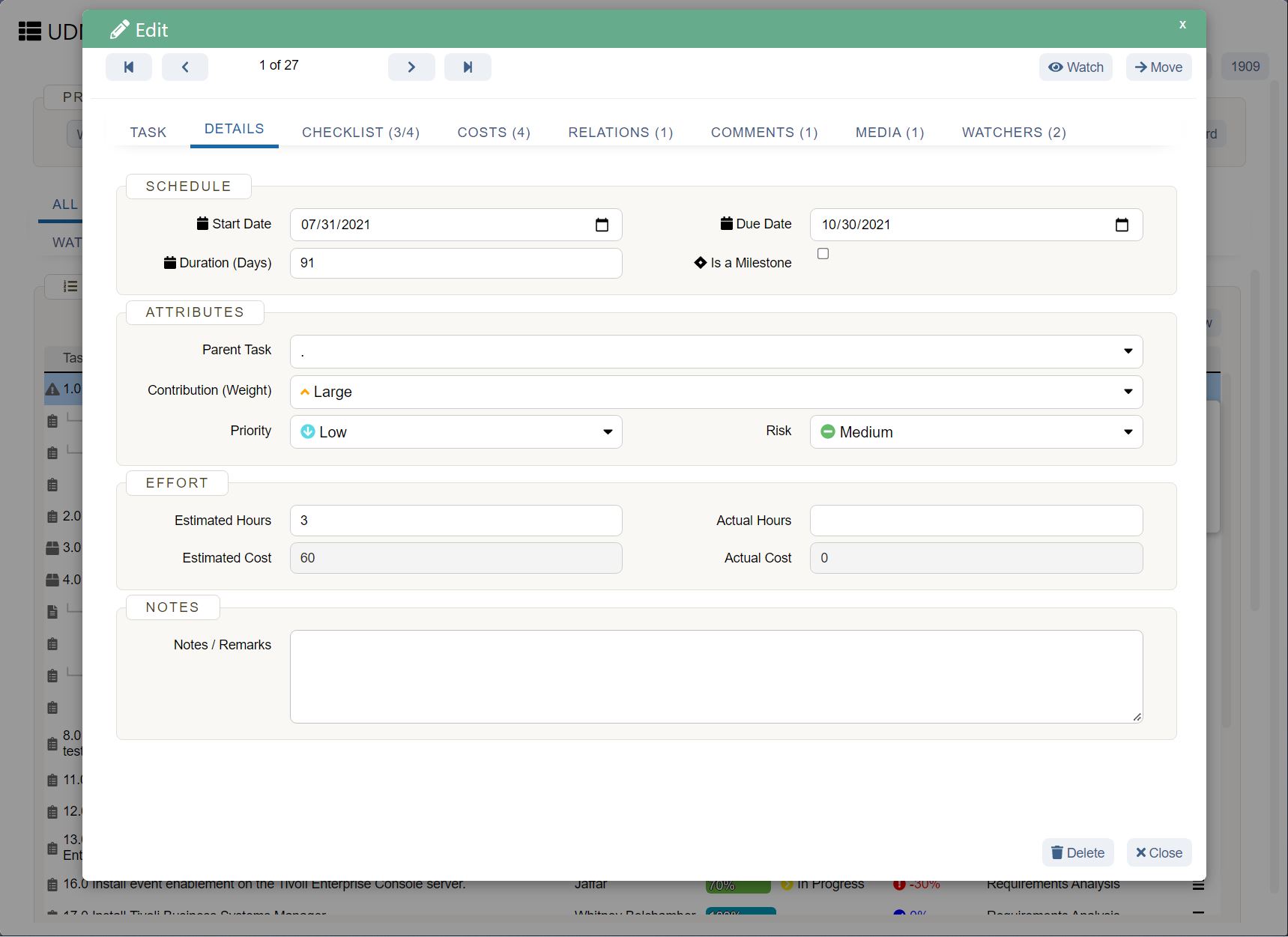

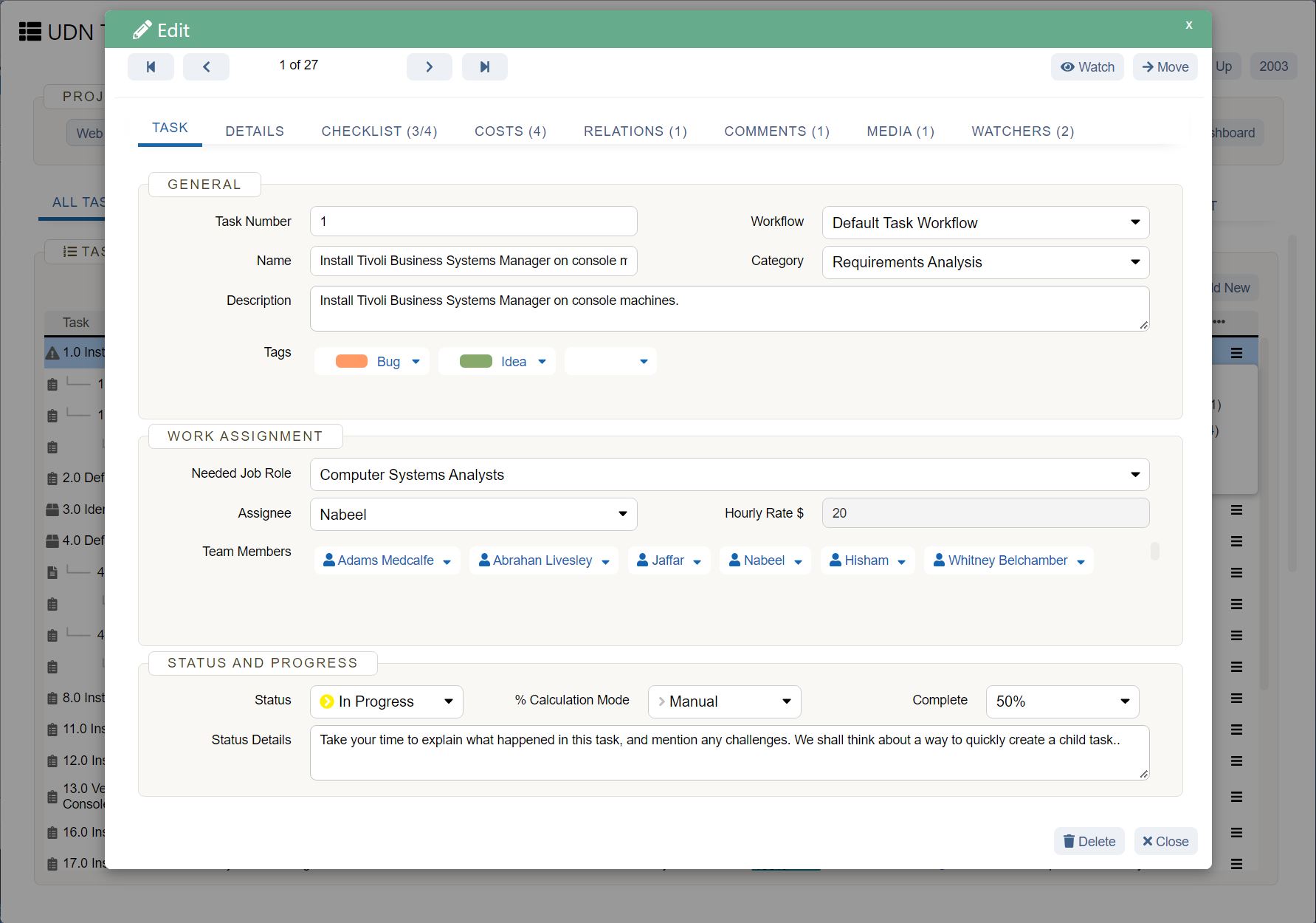

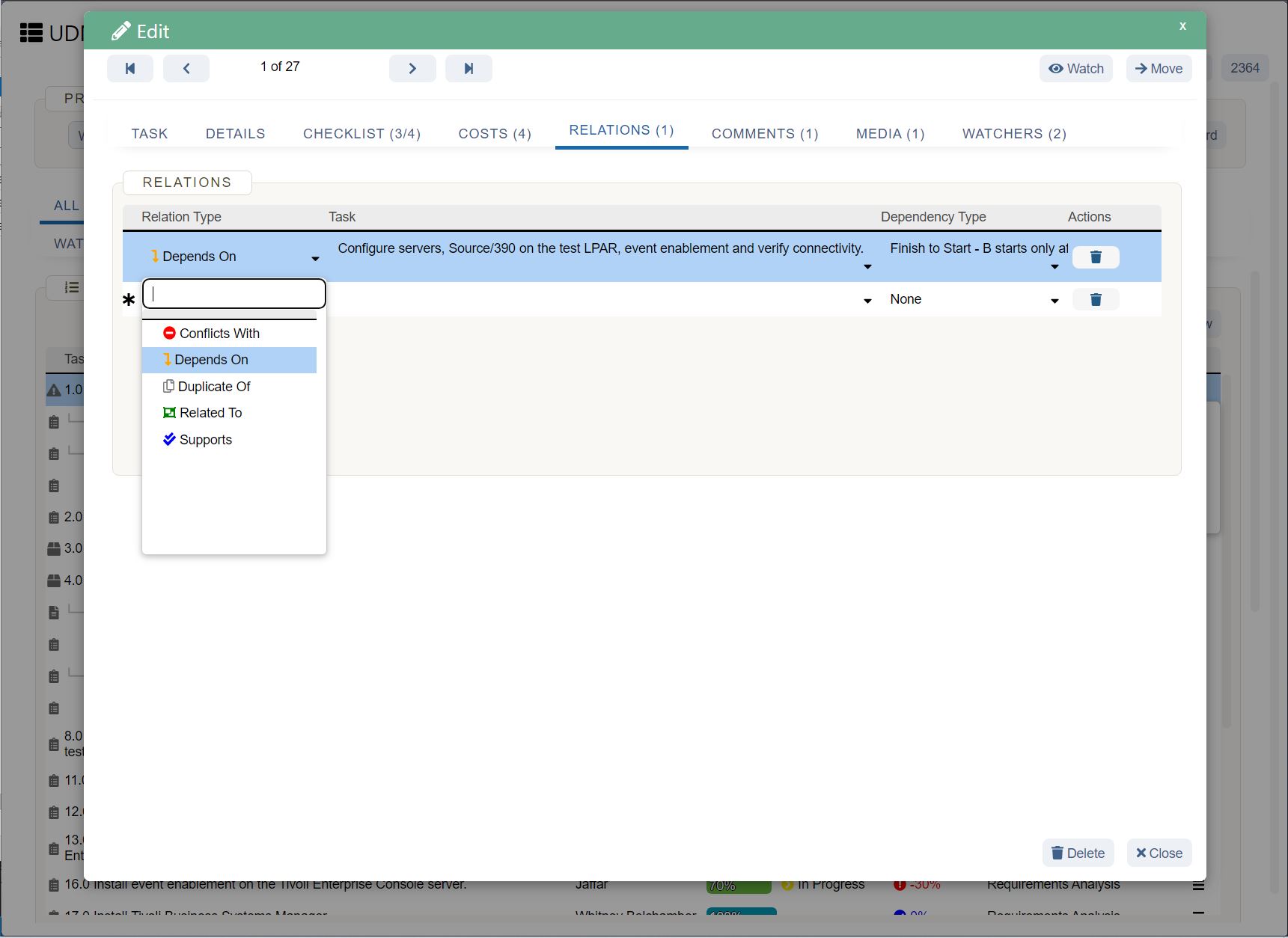

You can use a productivity tool like UDN Task Manager to track the time taken to complete a task!

UDN Task Manager makes it super easy to track time, so you don’t waste time trying to track it!

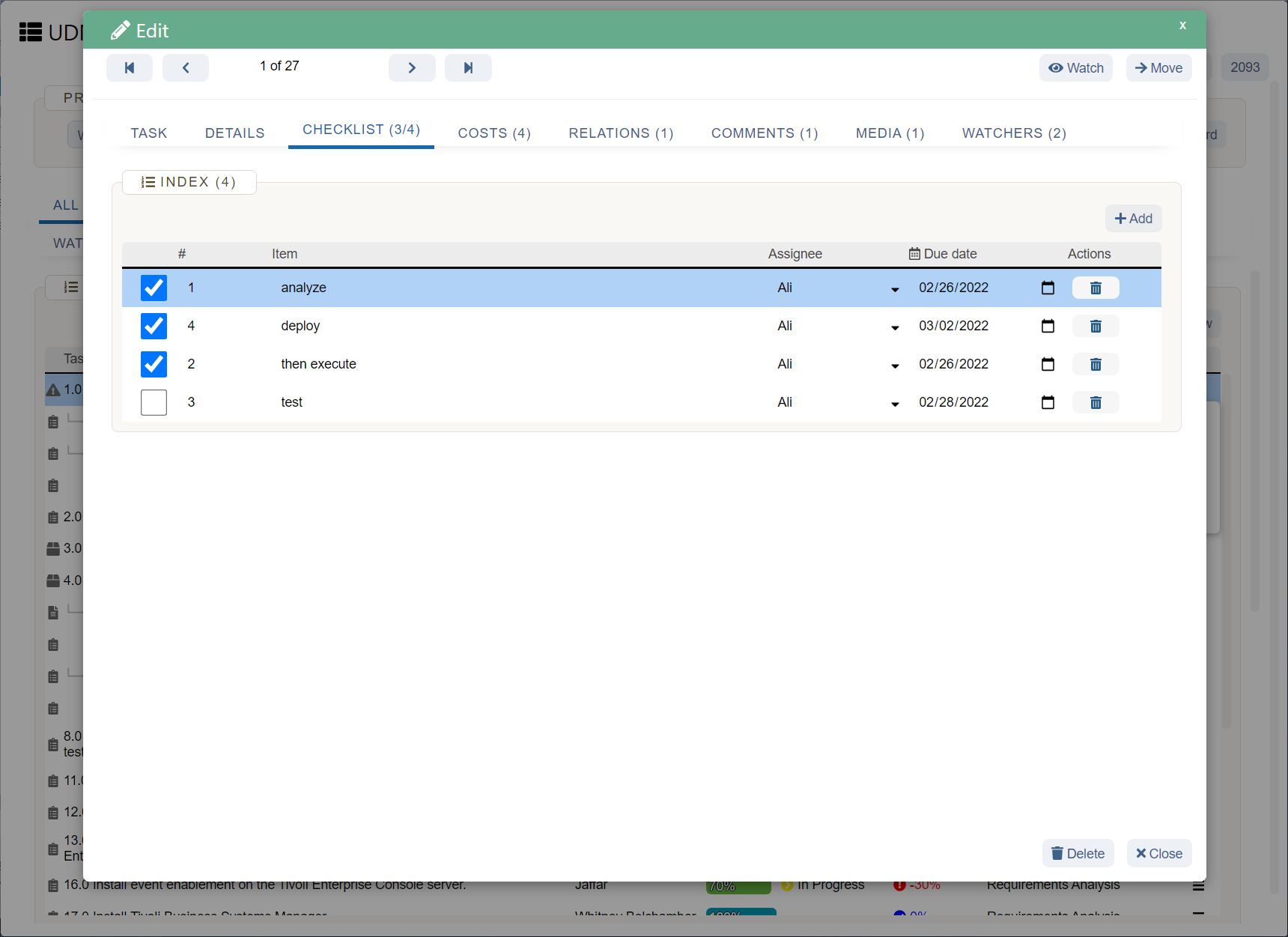

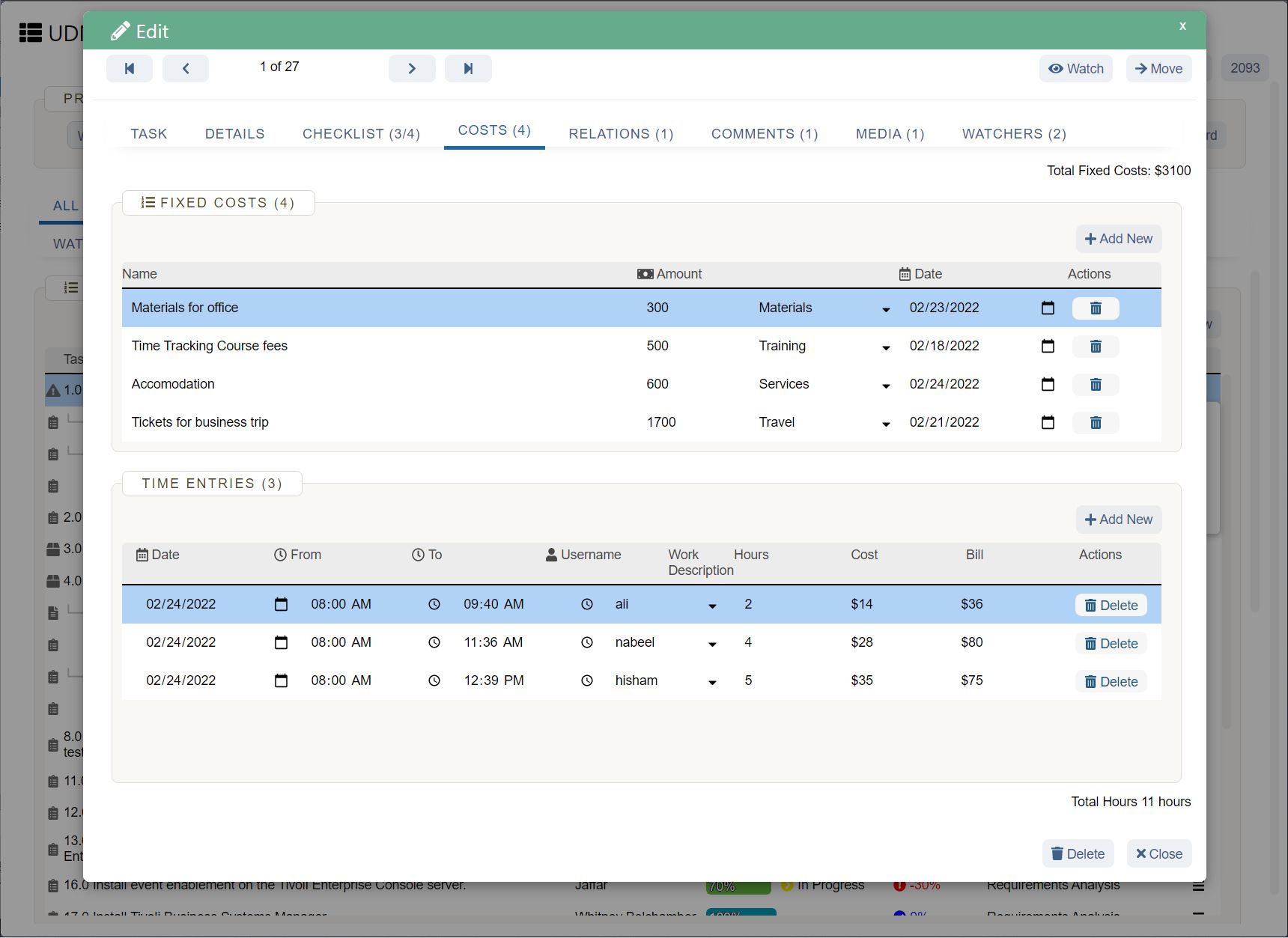

With its Native Time Tracking feature, you can measure the time spent on all your tasks within UDN Task Manager . You can also add notes, labels, and even classify time as billable hours (perfect for remote teams and freelancers .)

After you’re done with all your tasks, UDN Task Manager stores time tracked as a Report, so you know exactly how long it takes to complete a task.

Note: Already using a time tracking tool? D’oh!

No problem. UDN Task Manager allows you to integrate popular software like Time Doctor , EverHour , Toggl , and more.

Now back to our example:

After tracking your time, you discover it takes 20 minutes to evaluate one form. This will be your takt time.

Now here’s the calculation you need to do to find the available production time:

Available Time = Takt Time x Demand

So the production time will be (20 minutes x 40 forms) = 800 minutes or 13 hours and 20 minutes.

This way, you can estimate how long your projects can take, so you can plan them accordingly.

3. Identify and fix bottlenecks

What do you do when a machine malfunctions?

No, you shouldn’t threaten it, like Mr. Burns!

You should open it up and inspect its parts.

Similarly, when there’s a problem in the Lean manufacturing process, you’ll need to break the production into smaller cycles as each step of the process will have its own takt time.

You can then immediately identify the bottlenecks by determining which processes are taking longer than the ideal calculated takt time.

Once you identify the bottleneck, you can focus on that process step, when you’re creating a Kaizen (continuous improvement) plan.

Want to learn about every Lean principle in the book?

Check out our detailed guide on Lean.

What Are The Benefits Of Takt Time?

Even though takt time is an extremely simple concept, it’s powerful enough to supercharge the manufacturing unit of your company.

Don’t believe us?

There’s a reason Toyota swears by it !

Take a look at the benefits of tracking takt time in the Lean manufacturing process:

1. Easier production planning

Since your production system is usually consistent, it’s easy to plan out your shift schedule .

That is if you use takt time to create a value stream map.

Wait, what’s a value stream ?

It’s a sequence of steps that need to be followed to provide the product that customers want.

By using takt time while value stream mapping, you can see whether the manufacturing process is quick enough to meet customer demand.

2. Eliminates waste

When you don’t know how much your production rate should be, you might produce more than the customer’s need. Additionally, you’ll need to find a place to store all that additional stock.

And if your product is something perishable like beer, it could easily go to waste. When you know your takt time, you can avoid this by producing just the right amount of required units.

What Is The Difference Between Takt Time And Cycle Time?

While both cycle and takt times are used by Lean practitioners, they’re used to measure different things and are used at different times in the production cycle.

Takt time i s the rate at which you need to complete a product to meet the customer order.

Cycle time is the active time your team actually spends on completing a customer order.

However, many new Lean practitioners also get confused between cycle and lead times.

Well, that’s not a shocker, considering they look very similar and are always seen together, like Patty and Selma!

Cycle time is the time taken for the team to work on a customer order or task from start to finish. If the bottling plant produces an order for Moe from 2 pm – 7 pm, then the cycle time is 5 hours.

Lead time is the time between when the customer, Moe, first placed the order to when the final product was delivered.

So if Moe placed an order for a keg of beer at noon, the beer was produced between 2 pm – 7 pm, and the beer truck arrived at his tavern at 9 pm, then the lead time was 9 hours (12pm to 9pm).

But how do you measure lead and cycle times ?

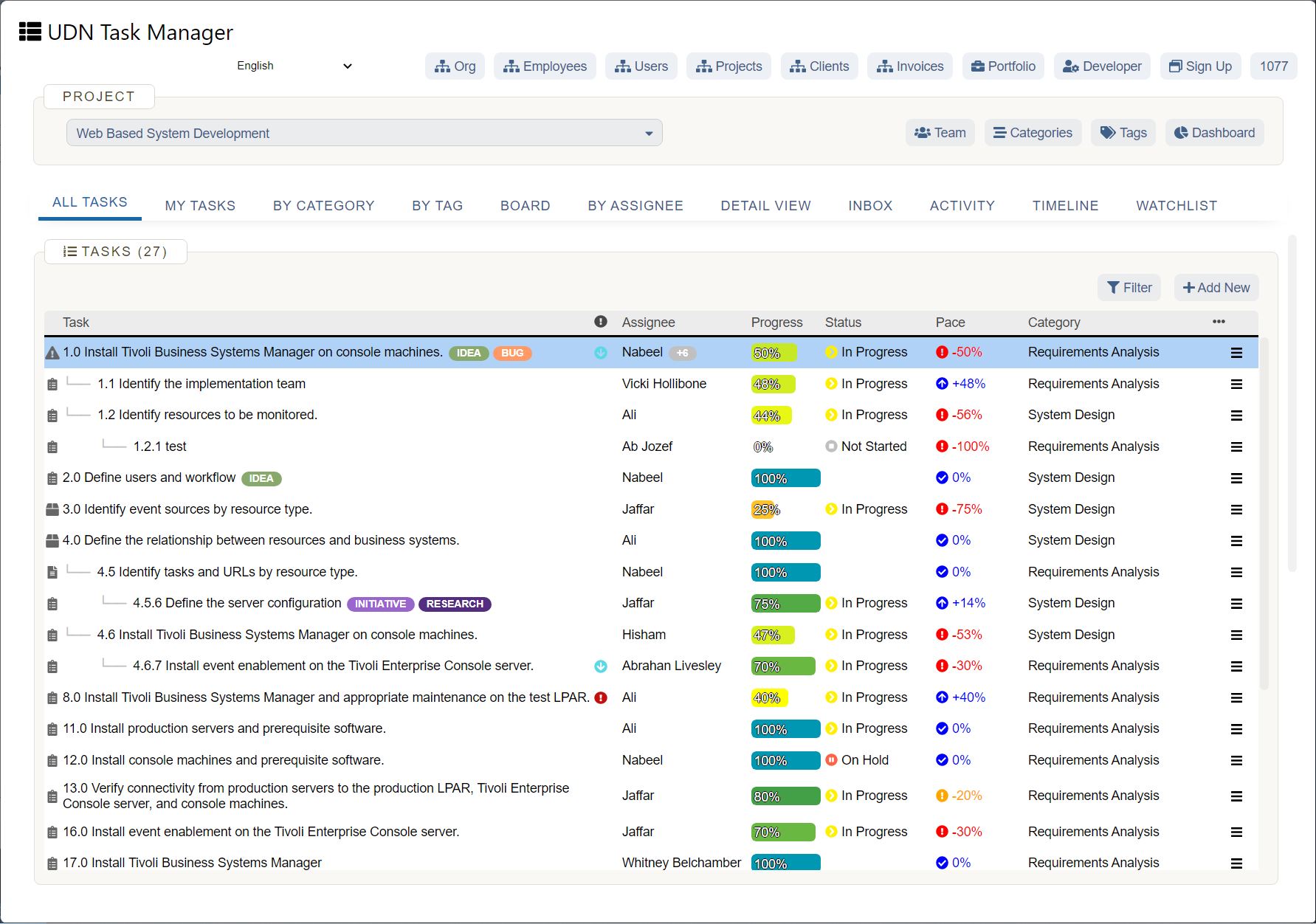

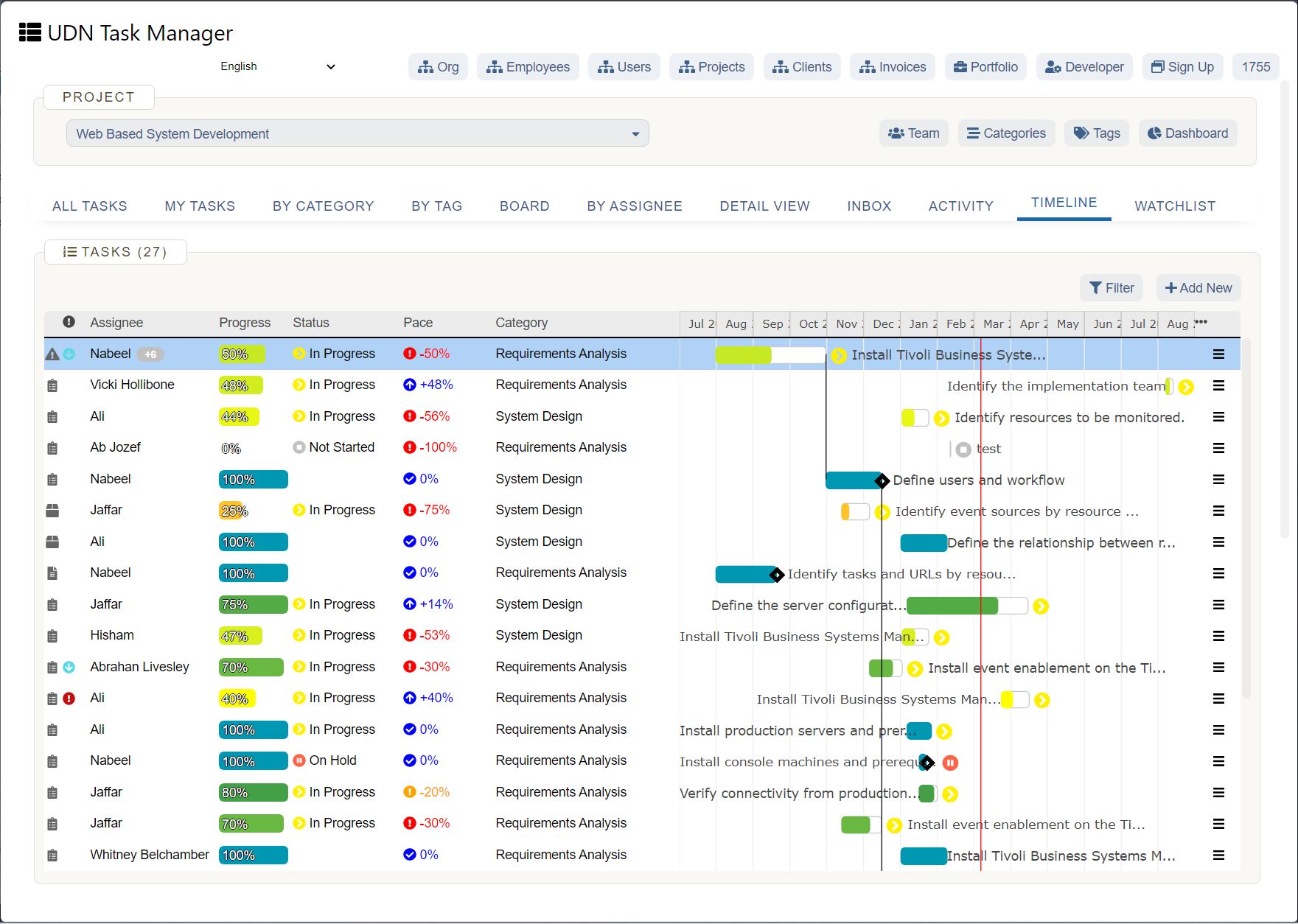

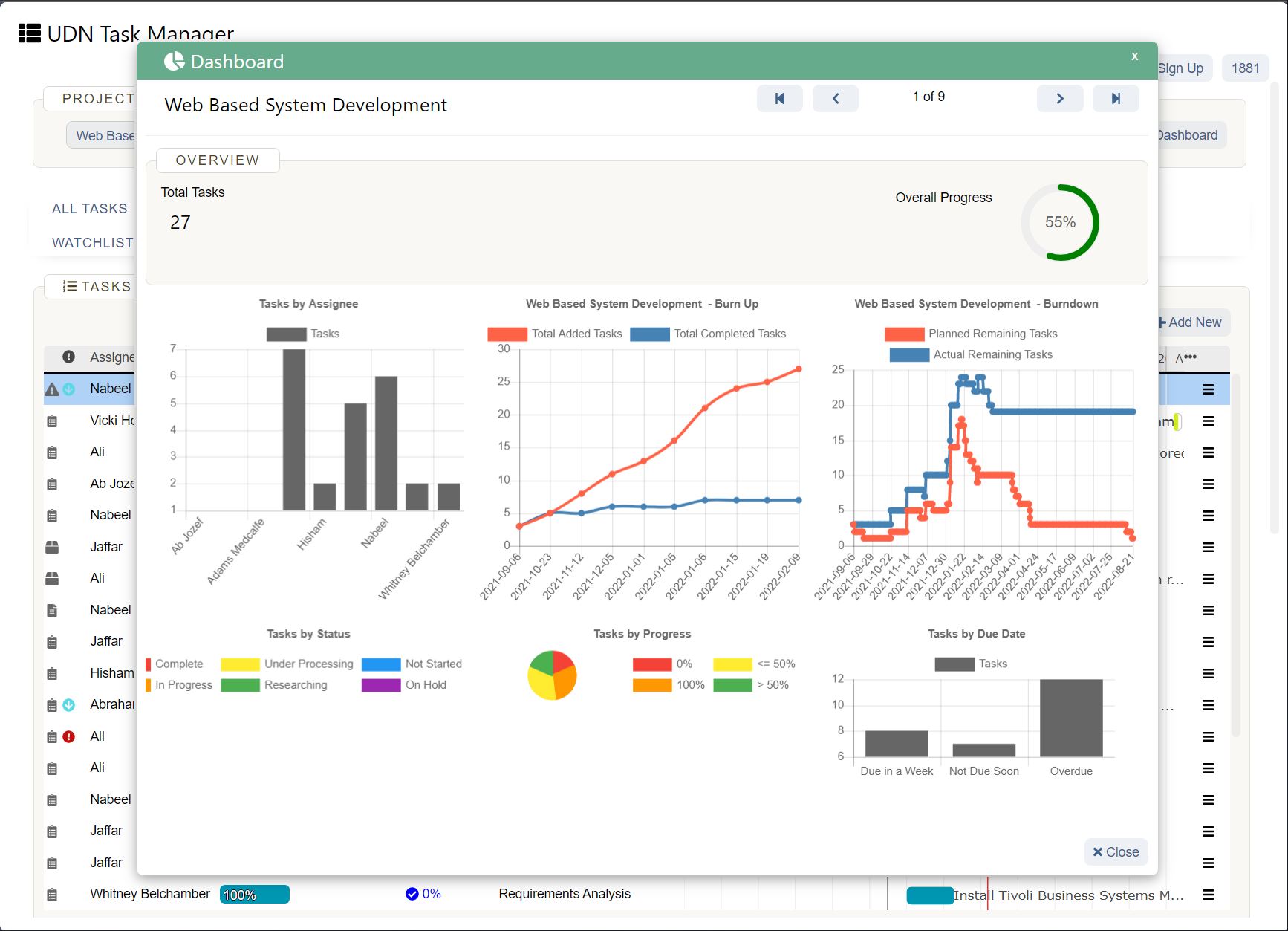

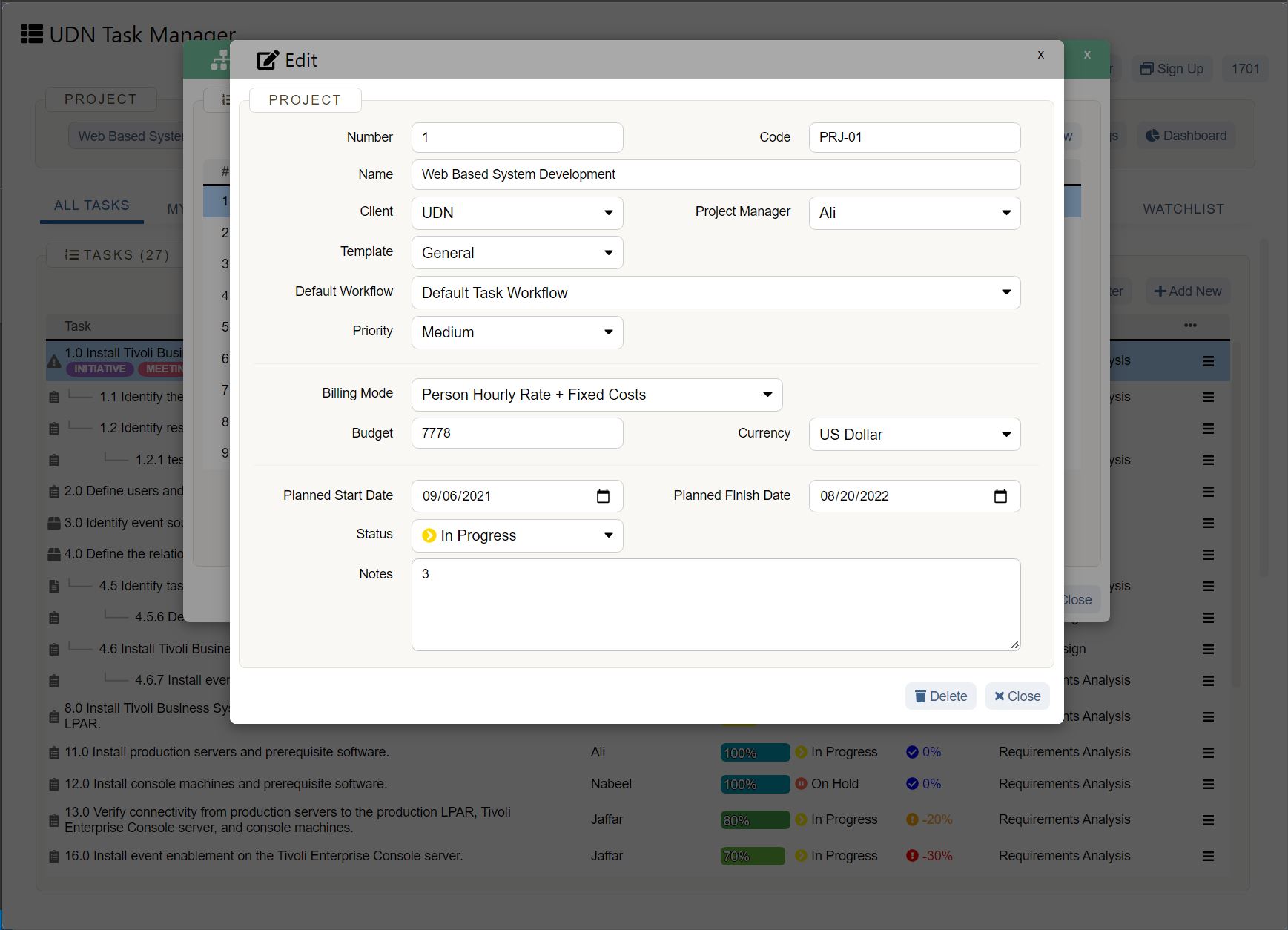

UDN Task Manager lets you visualize your lead time and cycle time with its Dashboard feature.

With the Lead Time Widget, you can determine the average time taken to close the task from the second it was first created. And with the Cycle Time Widget , you can figure how long a task was actively worked on.

You can also customize both of these Widgets by choosing the:

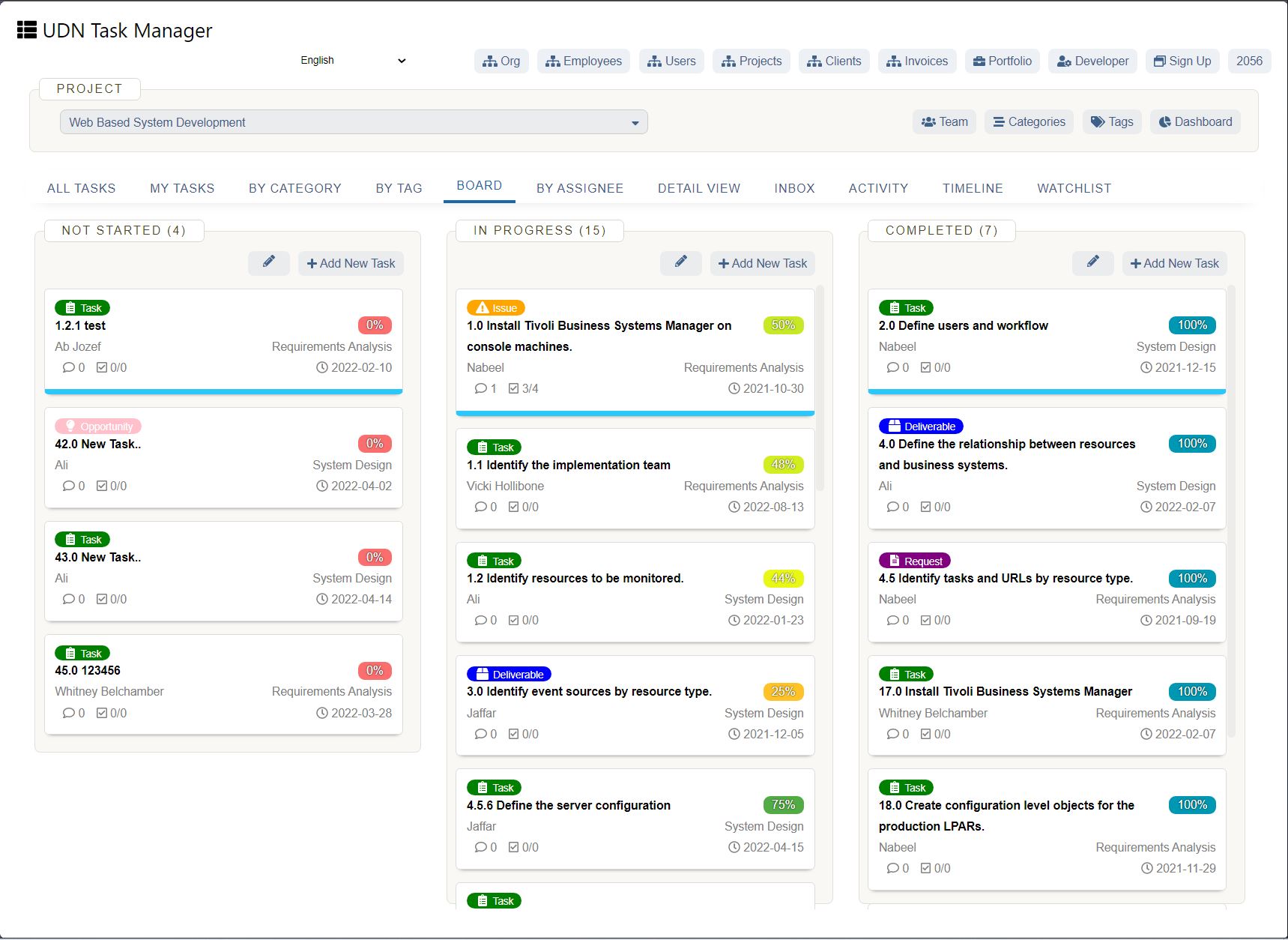

But that’s not the only Lean and Agile unit you can track in UDN Task Manager .

With Dashboards, you can set up your control panel just like Homer.

Here are a few other Agile metrics you can visualize on one screen:

However, that’s just a taste of the features you’ll get with UDN Task Manager .

There are more UDN Task Manager tools available than the number of donuts Homer can eat on an average day (and that says a whole lot!)

Here are a few features that can help all your teams boost their productivity:

Conclusion

So what is takt time really?

It’s a metric that helps you figure out how quickly you should manufacture your products to perfectly meet customer demand.

This way, you produce only what’s needed , and there’s no extra stock collecting dust in storage!

Is it any wonder why takt time and Lean worked so well for the Toyota production system?

However, remember that you can’t manage takt time by yourself. You need the help of project management tools like UDN Task Manager !

It’s got all you need to manage Lean manufacturing projects like a Kanban board , Dashboards, and Time tracking.

So get UDN Task Manager for free , and transform your company into a Lean, mean, productive machine!