What Is Lead Time? (Ultimate Guide)

Udn Webber

Managing Editor

Curious what is lead time ?

Shorter lead times (the duration between order placement and fulfillment) is one of the easiest ways to get more work done and increase customer satisfaction.

Whether it’s inventory management, supply chain management, or product development, lead time is the best way to gain a lead in business.

But how do you calculate lead time ?

And more importantly, what is lead time exactly?

In this article, you’ll learn the lead time meaning and how to calculate it. We’ll also highlight its benefits and a handy tool that can help you track it easily.

What Is Lead Time?

Lead time is the total time spent from the moment a customer places an order to the time the order is delivered.

Depending on the type of process an order is a part of, it can be expressed differently:

Confused?

Don’t worry! To summarize it…

What are the types of lead time?

There are mainly four types of lead time:

Let’s take a detailed look at them:

Customer lead time is the amount of time taken between the acceptance and fulfillment of an order placed by the customer. The order fulfillment can either be a doorstep delivery or pickup from an accessible location on the requested delivery date.

For example, if El Profesor from the TV series Money Heist , placed an order for 20 red costumes, the customer lead time is the time between his order confirmation and the day he receives the order.

Material lead time is the total time taken to place an order from a supplier and receive the shipment. These are usually bulk orders of raw material that are required in the manufacturing process or as inventory.

So while customer lead time accounts for delivery time to the end consumer , material lead time is mainly concerned with the manufacturing process.

For example, the manufacturer of El Profesor’s red costumes places orders for the procurement of raw materials (like red cloth and thread) from a supplier. The material lead time, in this case, is the time between when the order was placed by the supplier and when it was received.

Considering that the required raw material is available, and there’s no supply or logistics delay, production lead time is the total time taken to produce and ship a product to the desired location.

In this example, the production lead time for El Profesor’s order is the time taken to manufacture 20 costumes and ship it to the desired address.

Cumulative lead time is the sum of material lead time and production lead time. It is the total time taken from the moment an order was confirmed to its shipment , assuming that the order for raw material had to be placed.

Now that all the parts and types of lead times have been unmasked , let’s learn how lead time is calculated.

How Is Lead Time Calculated?

The lead time formula is:

Lead time = Delivery Date – Request Date

Since there’s a lot of steps usually involved in this process, a lot of events take place between the ‘Request Date’ and ‘Delivery Date.’

And that’s why the above formula can be further broken into components:

Lead Time = Pre processing Time + Order Processing time + Wait time + Transportation time + Storage time + Inspection time

Each component can be defined as:

Check out our comprehensive take on how to calculate lead time .

Confused?

Here’s an example:

If El Profesor placed an order for 20 Dali masks from a mask vendor on 21st September and received it on 26th September, then:

So,

Lead time = 26th September – 21st September = 5 days

This could be a sum total of:

Sounds simple, right?

Just like the heist did in theory .

But in reality, every process requires much more effort.

So why is lead time important for a production process ?

Let’s take a look:

Why Is Lead Time Important?

Timing was the most important factor in the Royal Mint of Spain heist.

Why?

Because without properly timed execution of the plan, things can go wrong.

Even for this genius!

Similarly, timing is an essential factor for most other business operations.

Let’s take a look at the four reasons why a short lead time is important for your business:

1. Increases customer satisfaction

Customers want quality service in less time, with minimal effort, and at a reasonable price.

And you know the saying: the customer is always right!

If you have shorter lead times, you can give them exactly what they want by:

Additionally, long lead times can force a customer to look for alternatives. So if your business is that alternative that fulfills demand with shorter lead times, you can satisfy and gain more customers!

2. Facilitates cost savings

Longer lead times would mean:

Sounds like a checklist of everything that can go wrong, right?

On the other hand, shorter lead times will help you save all these additional costs and help you deliver on time. Additionally, short lead times translate to greater order fulfillment, which means increased cash flow.

3. Offers better inventory control

Placing large bulk orders every few weeks can leave you with excess inventory in your warehouse.

And that’s not a very good way to run your business.

Why?

It increases your warehouse storage costs and your unused inventory might become obsolete.

However, if you have shorter lead times, you don’t need to order things in bulk as your entire processing process is quick. This helps to keep your inventory stocked with just the right amount of items so your business runs without the strain of too little or too much inventory.

4. Makes the production process more flexible

With shorter lead times, you can be more flexible and creative.

So if you’re producing Dali masks, you have enough time to ponder over questions like:

This ability to implement last-minute changes is only possible when you have short lead times as you can quickly edit things without delaying the order and compromising customer satisfaction.

Moreover, short lead times give you the window to quickly adapt to variability in market trends.

All without any fear of incurring losses!

How Can You Reduce Lead Time?

Now you’re aware of all the amazing benefits of short lead times, one question remains…

How do you reduce it?

You can:

Formula? Check .

Reasons to reduce lead time? Check.

Ways to reduce long lead time? Check.

The only thing left? Calculating lead time and beginning inventory optimization.

Thankfully, we have the perfect tool to help you record lead times for your processes.

What’s The Best Way To Track Lead Time?

By using a dedicated tracking tool!

I mean, with numerous steps in a process , tracking each separately can be quite a task , right?

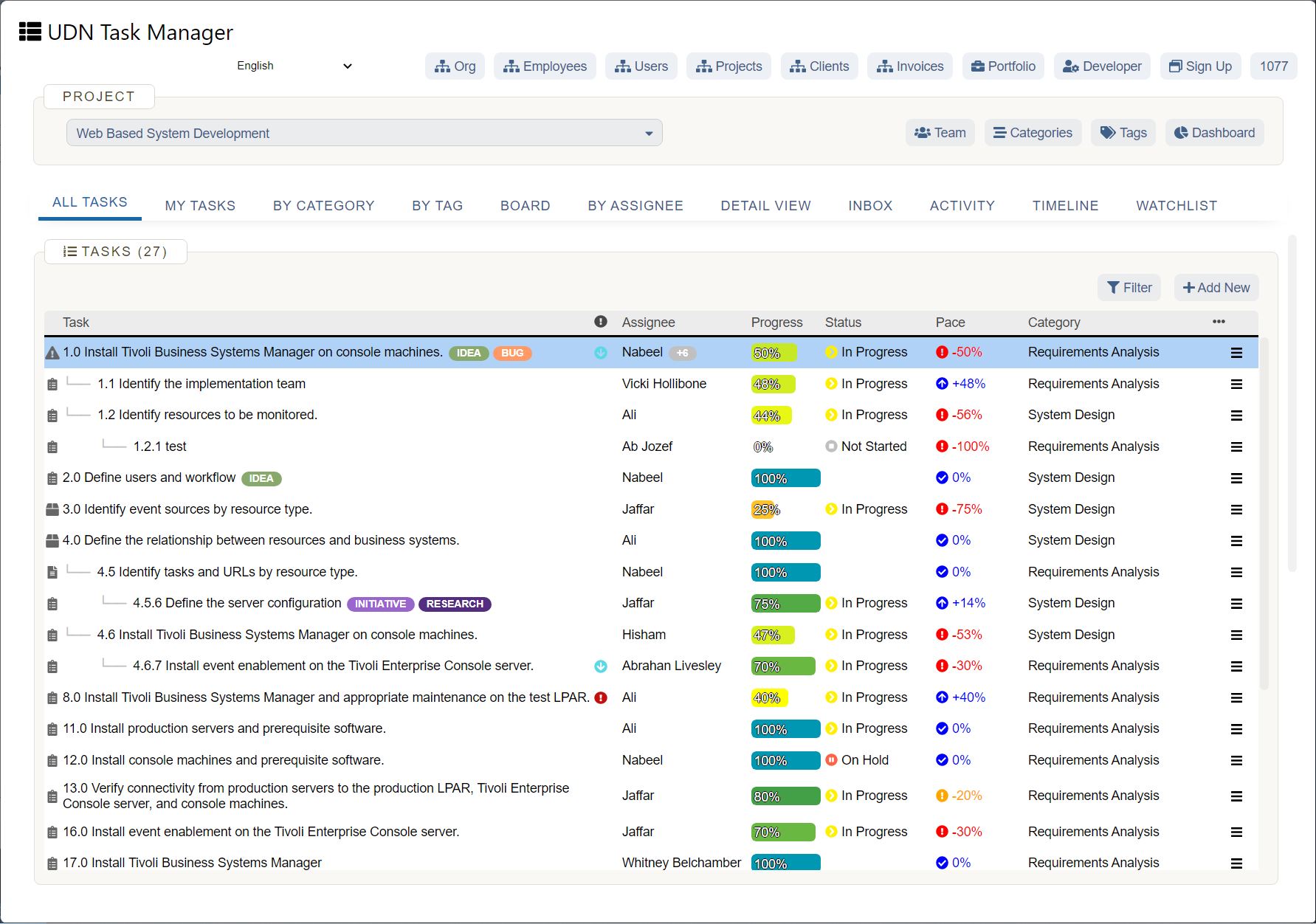

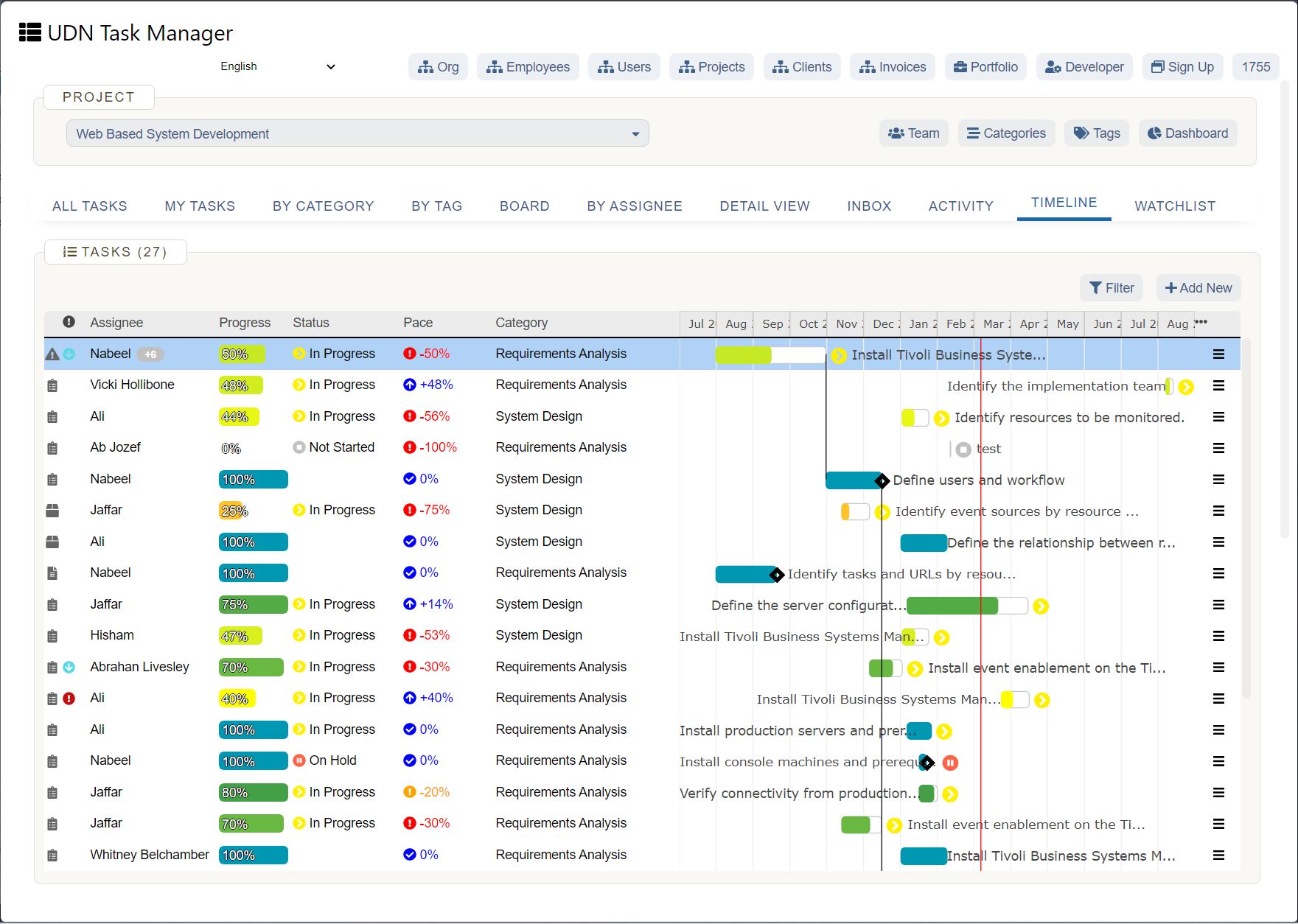

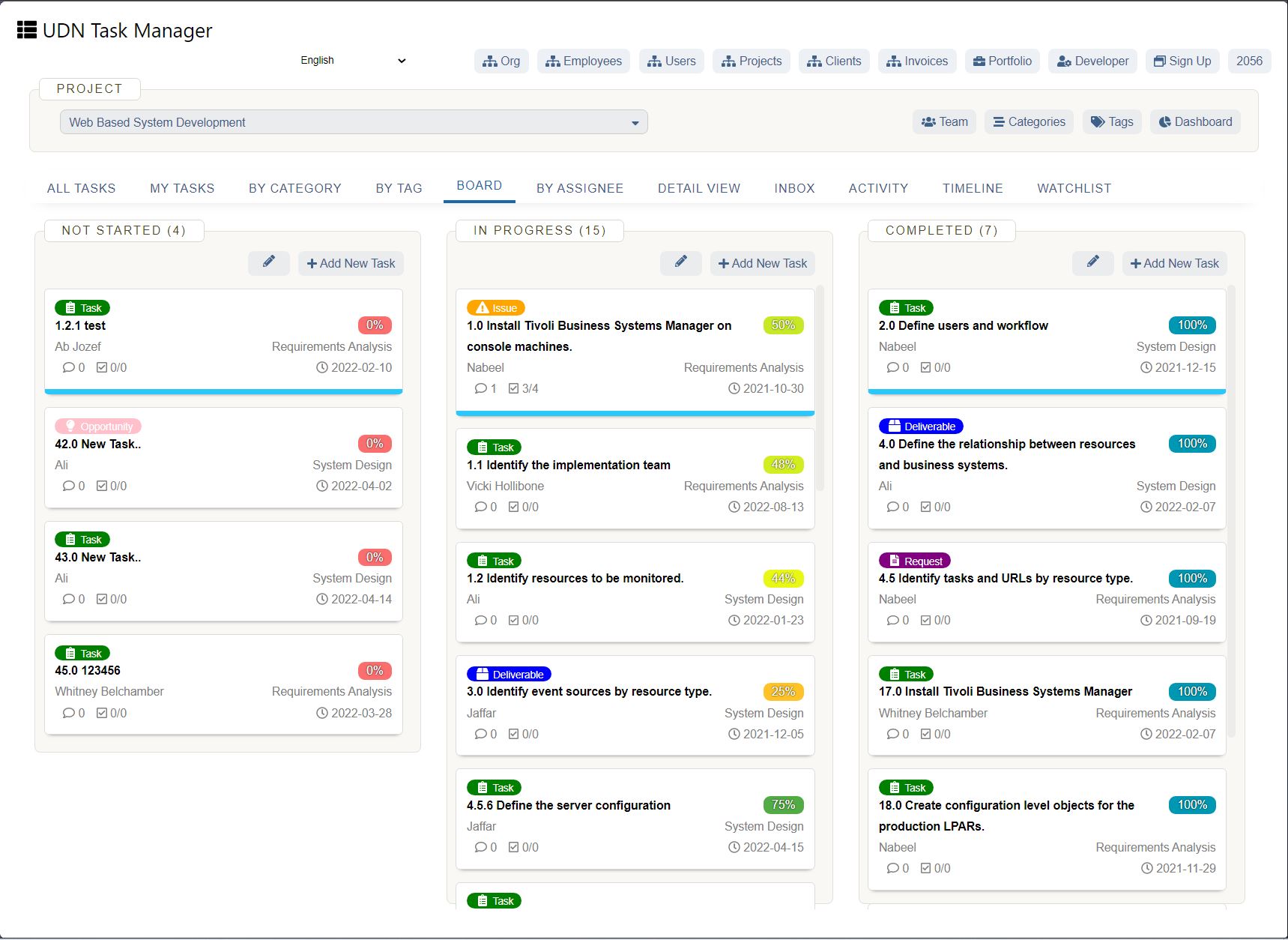

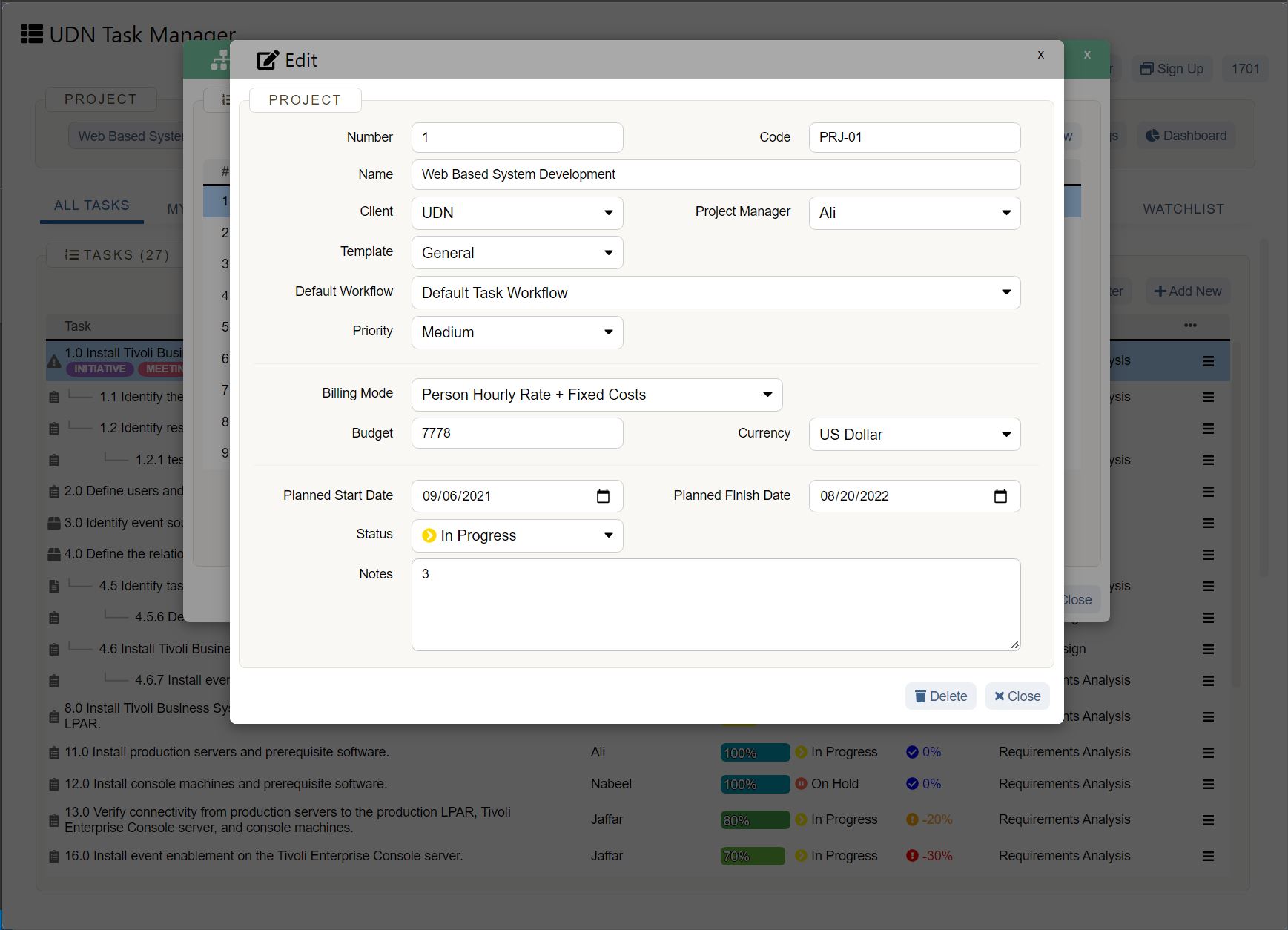

Luckily, a project management tool like UDN Task Manager is all you need.

What’s UDN Task Manager ?

UDN Task Manager is the highest-rated project management tool in the world and is the only tool you’ll need to efficiently manage all your projects.

Whether it’s workflow automation , Agile transformation , or virtual team management , UDN Task Manager can easily handle any task!

But how does a project management tool help in tracking lead time ?

UDN Task Manager ’s advanced tracking features, Agile charts, and customizable widgets help take care of all your lead time tracking needs.

And since it’s a versatile project management tool, you can use it for more than just lead time tracking.

But first…

How does UDN Task Manager help you track lead time?

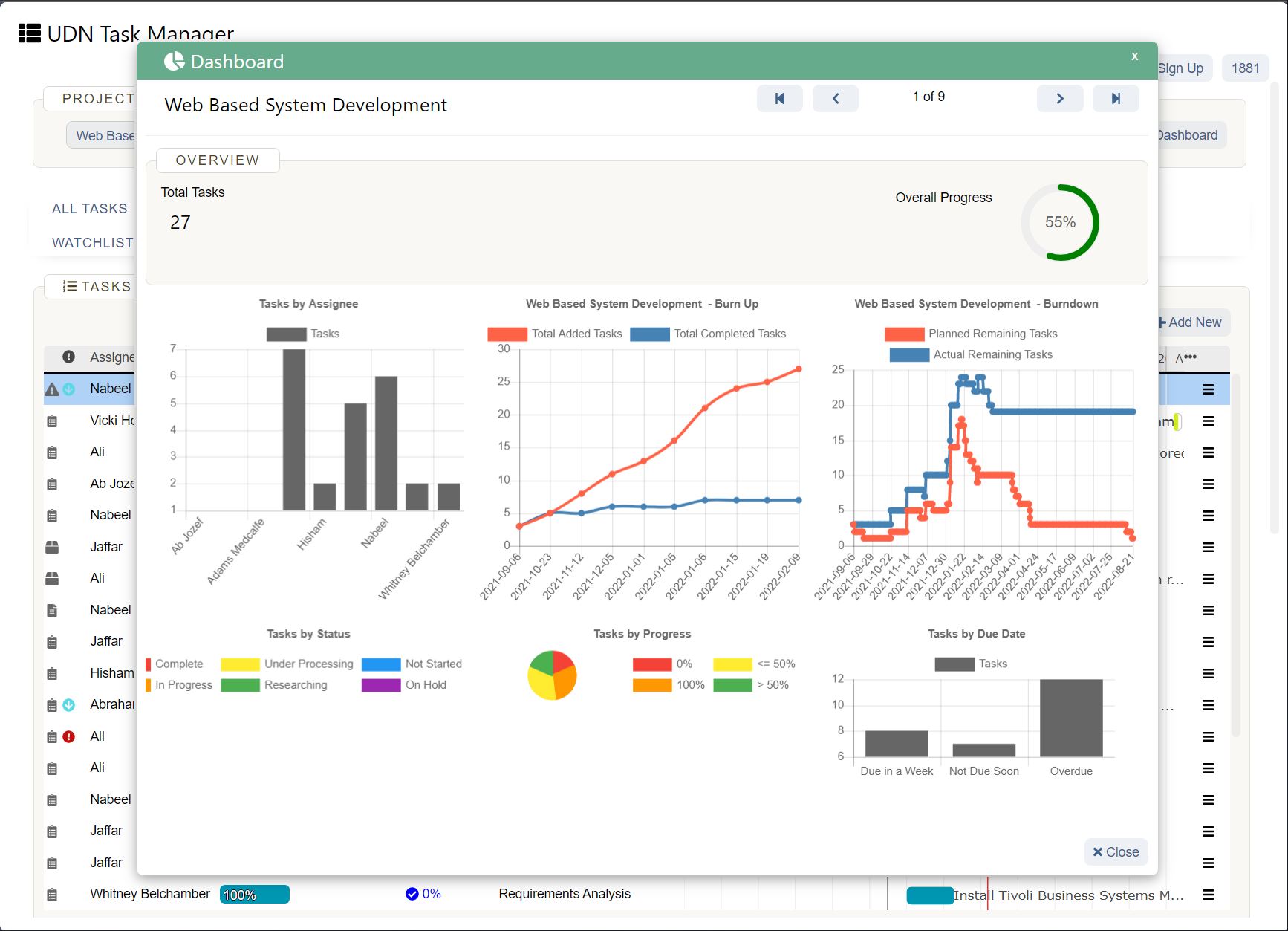

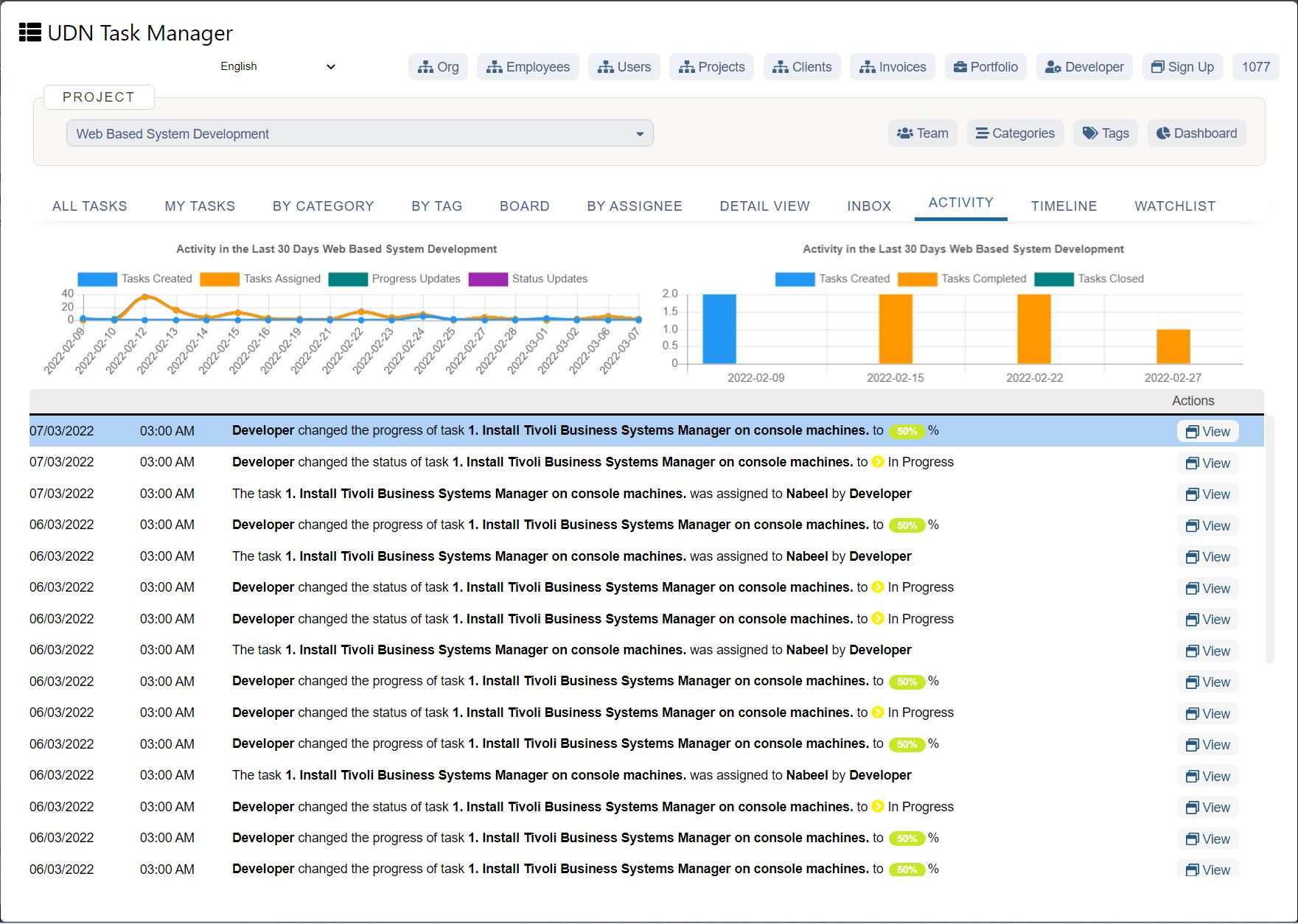

UDN Task Manager ’s Agile Dashboards offer super useful tools like Sprint Widgets to help you track lead time easily.

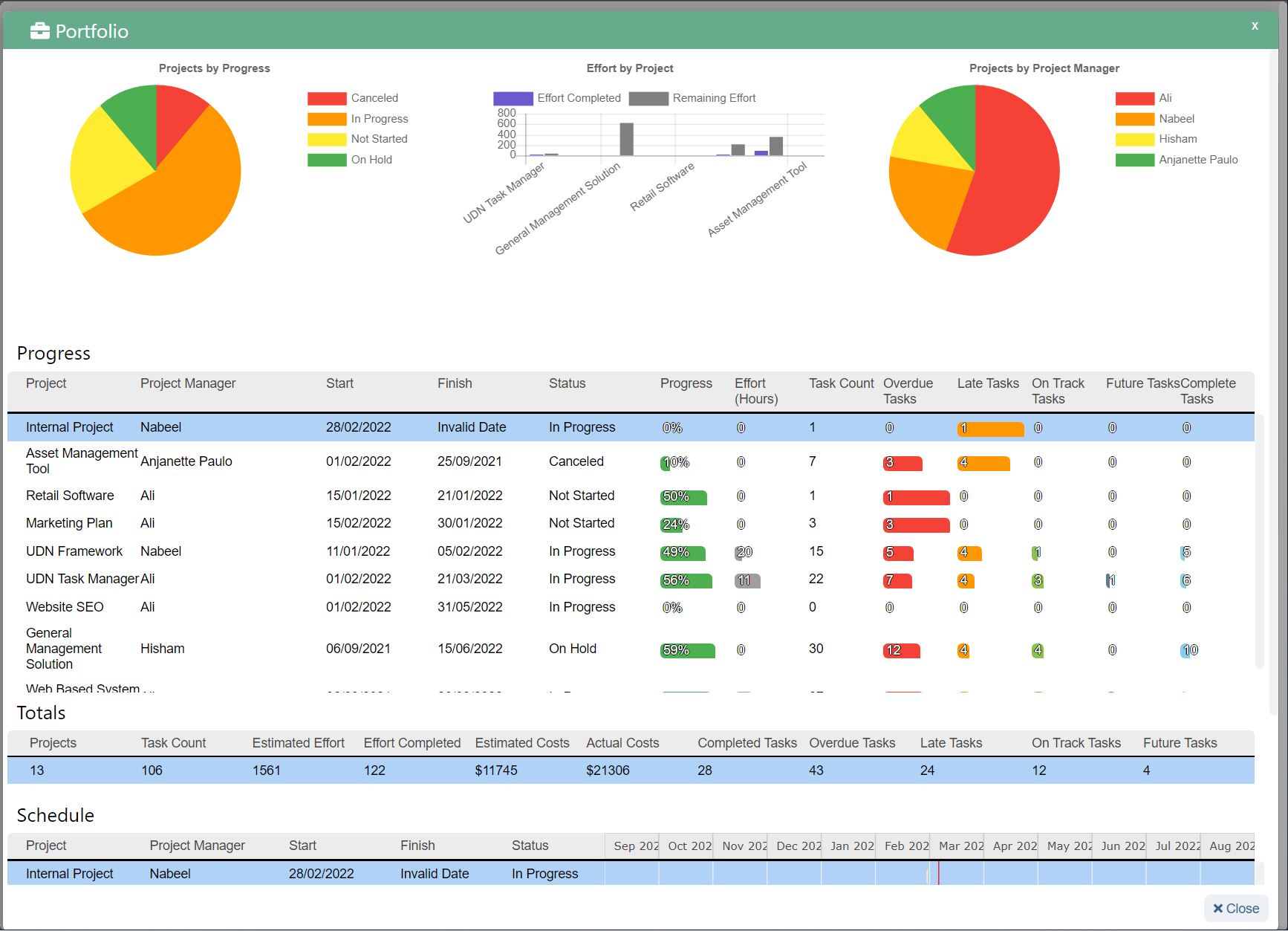

The UDN Task Manager Dashboard provides a high-level overview of your entire workspace.

Sorta like El Profesor’s mission control center!

Sprint Widgets like the Lead Time Graph on your Dashboard provide valuable insight into your Sprints . In UDN Task Manager , the Lead Time chart depicts the average time it takes to complete a task after it’s created.

Customize the Lead Time graphs with:

You can even add various Agile charts like Burndown Charts , Burnup Charts , Velocity Charts , and Cumulative Flow Charts to your Dashboard.

What’s more?

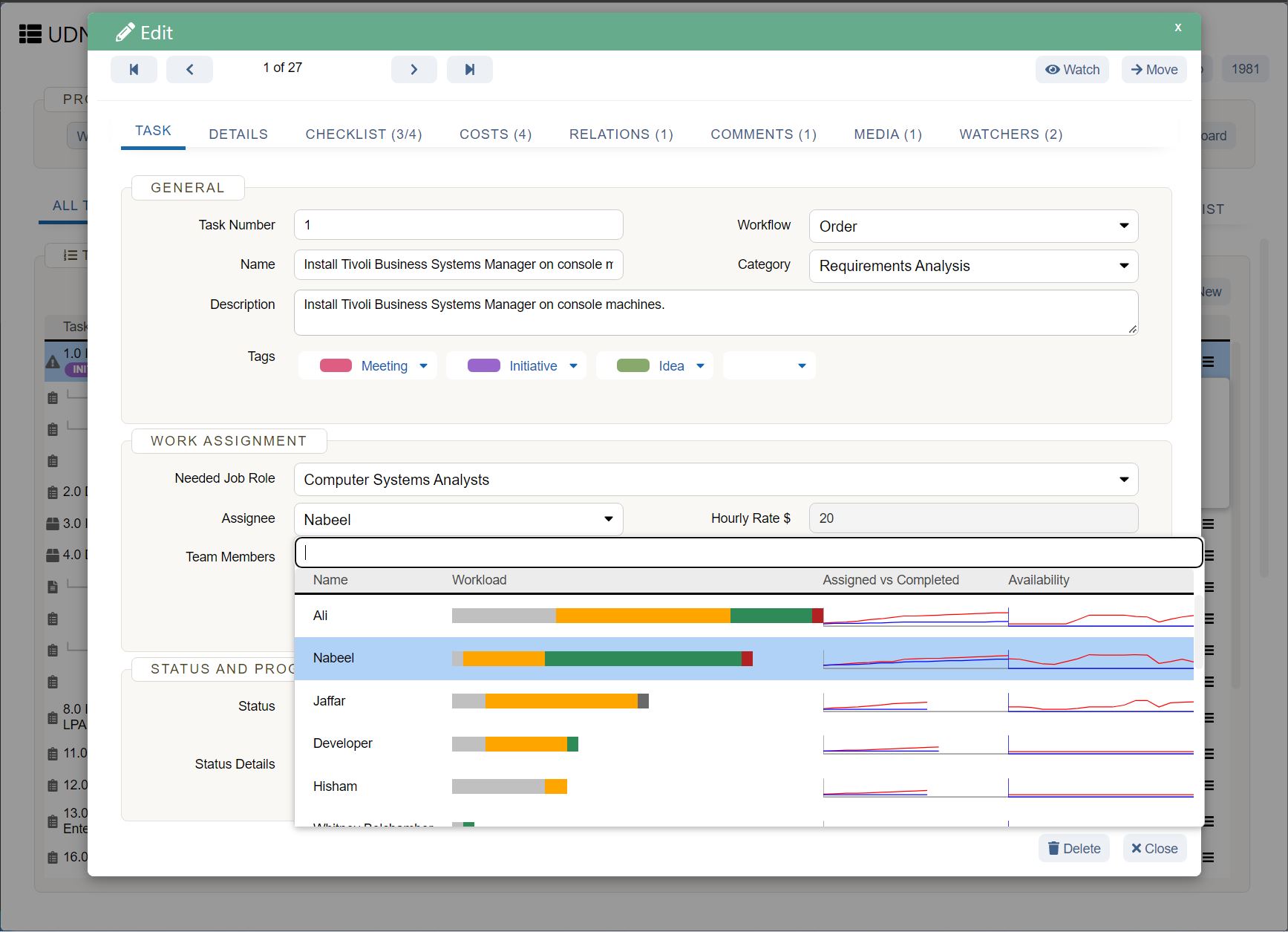

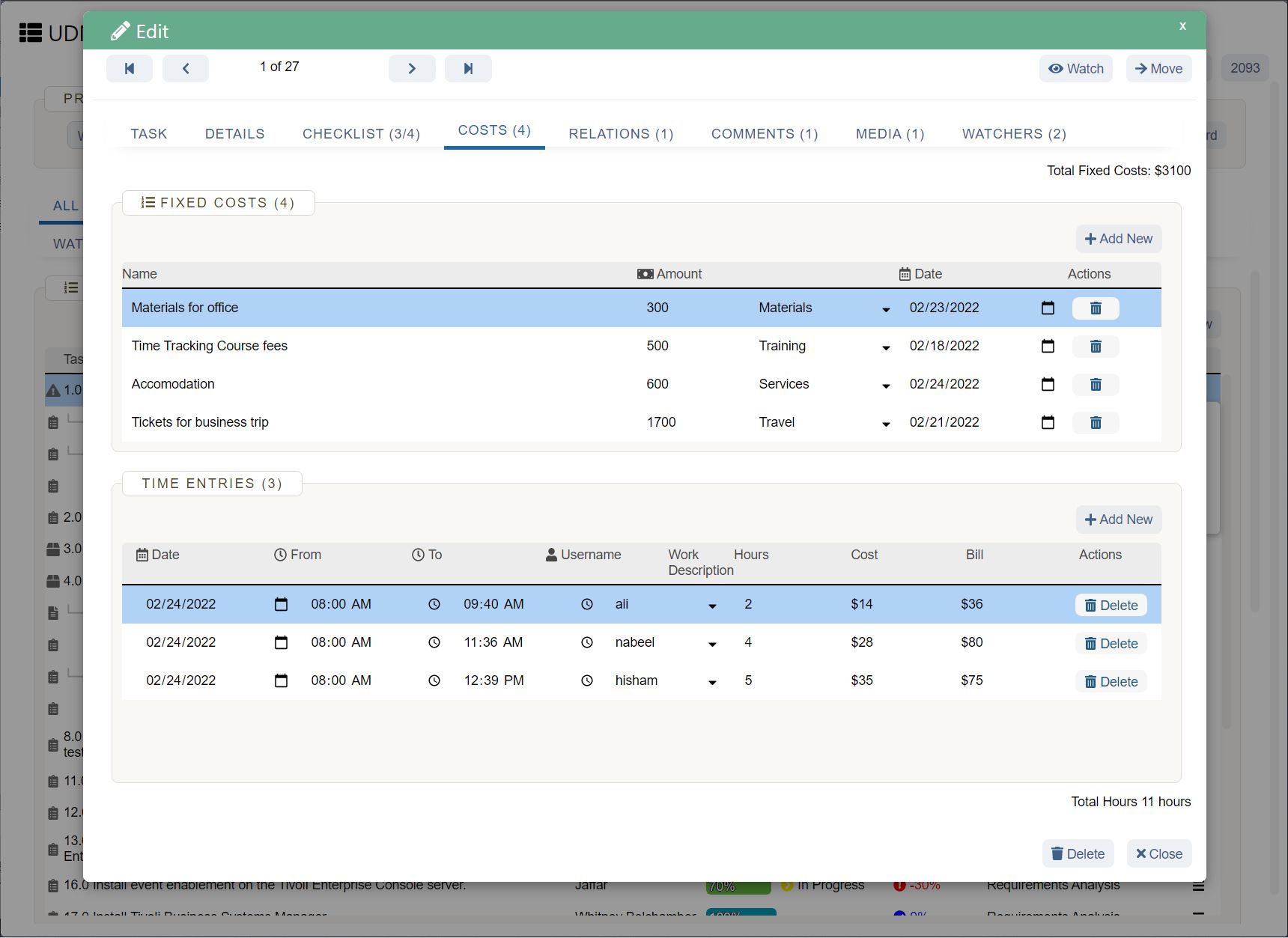

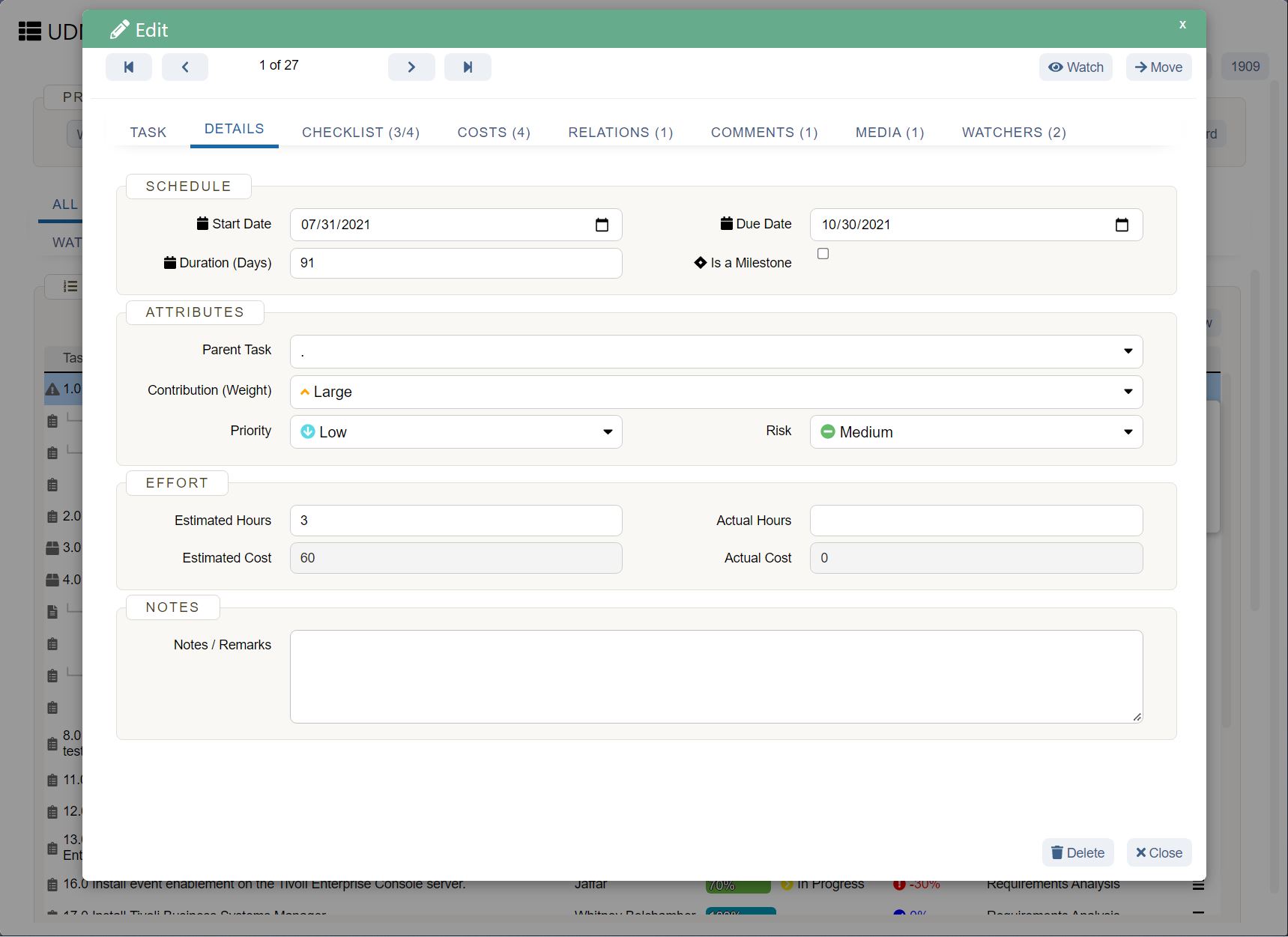

As UDN Task Manager lets you calculate crucial project metrics like lead time and cycle time, you can use them to easily predict all future timelines and set Time Estimates .

All you need to do is add the number of billable hours each task and subtask will take. UDN Task Manager then uses these numbers to calculate the total number of hours the project is expected to take. It also updates the estimated delivery dates in real-time.

For additional assistance, you can track how long each step takes you.

How?

UDN Task Manager ’s Native Time Tracking feature helps you accurately track the time spent on each task. With this feature, you can also view who else has worked on a particular task and for how long.

UDN Task Manager also integrates with third-party time tracking tools like Everhour , Time Doctor , Toggl , and more for seamless project management.

Thought we were done?

Just like Money Heist, there’s always more to come!

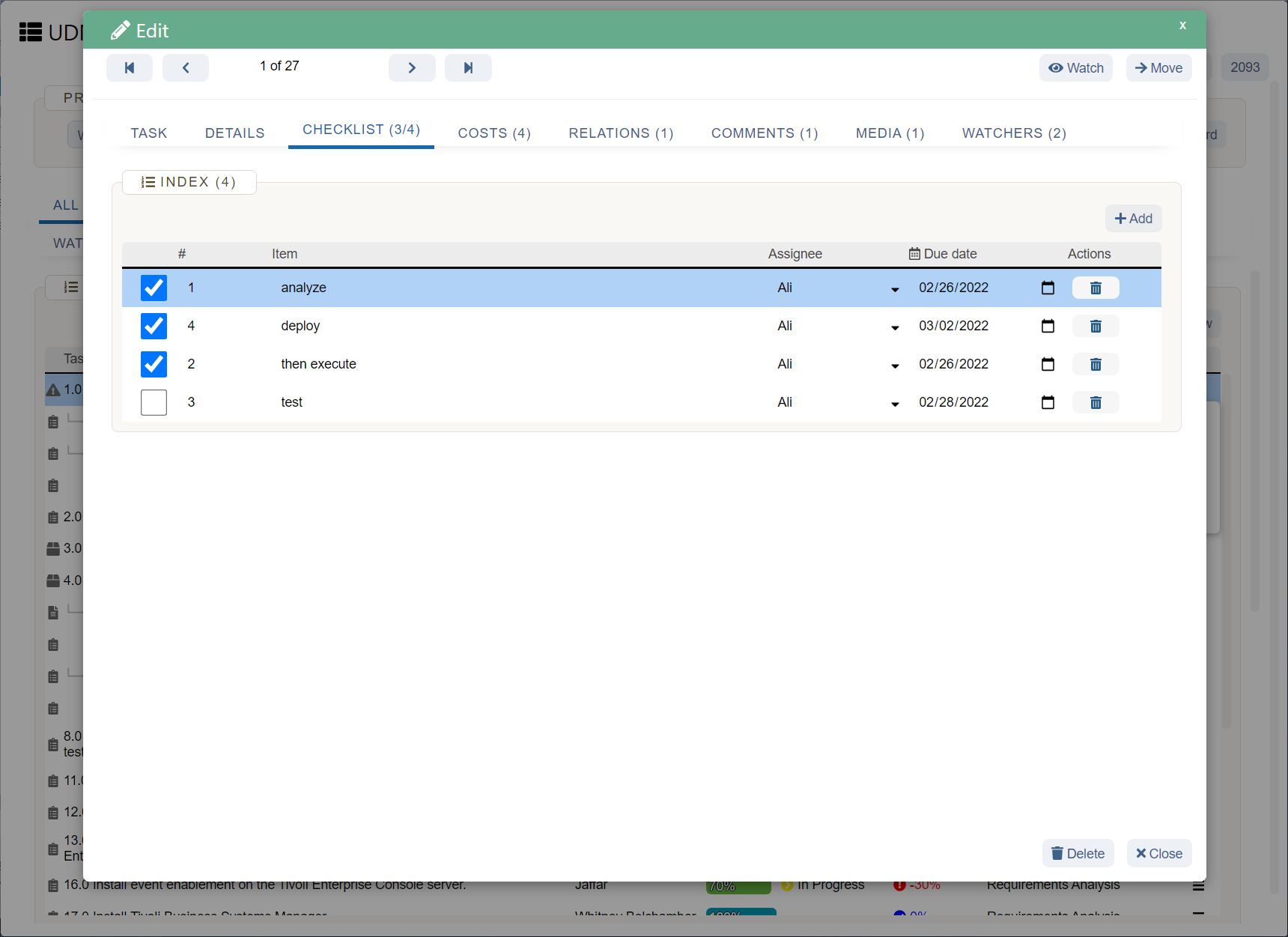

This powerful Agile tool offers additional features , like:

Conclusion

Short lead times are vital to staying on top of your business. With the ability to respond to changing market patterns, they help increase your cash flow as well as customer satisfaction.

Now that you know how to calculate it, you can easily use it for optimizing and reordering your supply chain and production process.

However, while knowing the lead time formula is a good start, you can’t keep manually calculating things every time.

Remember, it’s all about saving time.

And Agile project management tools like UDN Task Manager help you do exactly that!

From workflow automation and customizable widgets to project planning and resource allocation , it’s got everything you need to optimize your supply chain and production process.

So why not get UDN Task Manager for free today to improve your lead times and leave your customers like this: