The Key to Perfect Automation Is Imperfect People

In June 1982, a robot bowed to the chairman of General Motors, Roger B. Smith, and then bowed to Dr. Seiuemon Inaba, the president of Fujitsu Fanuc Ltd. After these pleasantries, the robot reached forward and gently cut a ribbon in half to open the GMFanuc Robotics Corporation in Troy, Michigan.

At the start of the 1980s, Japanese car manufacturers were eroding GM’s 48% share of the market, and the company was in need of transformation. The company was a joint venture between GM and Fujitsu Fanuc to form the largest robotics company in the world. The company was to supply over 1,000 robots to a new GM plant in Hamtramck, Michigan. It was part of a decade long, $90-billion-dollar initiative led by Smith to revitalize GM.

Smith handed down a “ reindustrialization ” mandate. He envisioned a fully automated, “lights-out factory” where the only humans needed were a few to supervise the legions of robots. The Hamtramck plant was a factory from the future. Smith called it “ the most modern auto plant in the world today .”

Rise (and fall) of the machines

In 1984, as the Hamtramck plant started operations, the factory a GM brochure called “the passage to the future” began to self destruct. In their book, “ Comeback ,” Paul Ingrassia and Joseph White explain:

“As Hamtramck’s assembly line tried to gain speed, the computer-guided dolly wandered off course. The spray-painting robots began spraying each other instead of the cars, causing GM to truck the cars across town to a fifty-seven-year-old Cadillac plant for repainting. When a massive computer-controlled ‘robogate’ welding machine smashed a car body, or a welding machine stopped dead, the entire Hamtramck line would stop. Workers could do nothing but stand around and wait while managers called in the robot contractor’s technicians.”

Throughout the 1980s, GM’s market share slipped to the low 30% range. In 1986, F. Alan Smith, a former GM CFO, quipped that GM should have just used the money to buy their 2 biggest competitors. “For $34.7 billion, given recent market valuations, GM could have purchased Toyota and Nissan. This would almost double GM's world market share, increasing our penetration to over 40% of the entire free world.”

So what went wrong?

Observers both inside and outside the company blame the speed at which the automation was implemented. “They had simply grafted robots onto the old, inefficient system… GM bet the entire Hamtramck production system on the proposition that leading-edge automation would work instantaneously,” wrote Ingrassia and White in “Comeback.”

Automation doesn’t replace process

Automation is a magnifier, not a solution . No matter how sophisticated the implementation, it won’t compensate for nonexistent or poorly defined processes. In fact, introducing automation into inefficient processes can actually cause more problems than it solves.

The best automation is built on rock-solid processes. But how do you ensure your processes are up to snuff? Visibility and consistency.

Visibility

The entire workflow must be mapped out down to the last detail. Everyone involved must understand how each part contributes to the whole. Only be seeing it all laid out can you spot and troubleshoot inefficiencies or roadblocks. It can be a bit of a laborious process, but just remember the results of bad processes are not eliminated by automation, they’re amplified.

Consistency

Former Ford President Phil Benton explained it this way, “Consistency of manufacture must come before automation.” The ability to produce consistent results is a hallmark of high-performing teams and organizations. When visibility is established, teams are able to hone and improve their process to yield consistent results and repeatable processes.

With these two key elements in place, internal processes should be ready for teams to begin identifying areas where automation could have an impact.

Humans are a critical part of the equation

GM tried to introduce automation into all parts of their processes, regardless of what the process was. Japanese automakers took a more calculated approach. They solidified and refined each process first, and if the process could benefit from it, designed and built the automation around it.

“I thought we were pretty adept at automation,” explains a former Chrysler executive , “until I walked through the doors to tour a Toyota plant in Japan and saw how well their products fit their processes.”

Even today, many parts of the Toyota production line have very little automation because some tasks are better suited for humans.

Evaluating the cause of some recent automation failures at a Tesla plant, a Bernstein Analyst said this: “Automation simply can’t deal with the complexity, inconsistencies, variation and ‘things gone wrong’ that humans can.”

Humans have mastered adaptive intelligence , the ability to adapt to rapidly changing situations. Life is complex and transformative. The ability to cope with unforeseen changes is a survival mechanism that has been built into our DNA over thousands of years. As new challenges manifest themselves, humans still have the edge when it comes to coming up with new solutions and countermeasures.

This isn’t just mentally either. We’re able to move and adjust our bodies as needed. While there are some automated systems that are equipped with environmental sensors, they’re still well behind biological systems. Our sense of touch and our awareness of where we are in relation to our environment is pretty astonishing.

For example, an optician named Achim Leistener is able to make perfect spheres better than any machinery because of his “atomic touch.” The employee-less Amazon Go stores have trouble when people move too fast or move items around.

So what should be automated? Routine and repetitive tasks are ripe or automation. Automating these kinds of tasks frees humans up for the most high-value, high-impact, and ultimately, most-rewarding work.

“Humans should produce goods manually and make the process as simple as possible. Then when the process is thoroughly simplified, machines can take over,” says Mitsuru Kawai, Head of Global Manufacturing at Toyota .

Even when automation is a good fit, humans are still needed to audit the ROI of the implementation, and update the systems as needs change or solutions evolve.

Automation is the future, just not how you may think

The potential of automation can’t be overstated — it will indeed transform the way we work. But it’s not a magic wand that will finish all of our work for us. Instead, think of it as a powerful toolset, and like any tool, we need to learn how to use it properly for the best results.

We believe automation will free us from repetitive, low-value work and open us up to a future full of rewarding challenges not tedious tasks. Leading companies are already using automation in project management to achieve more with less.

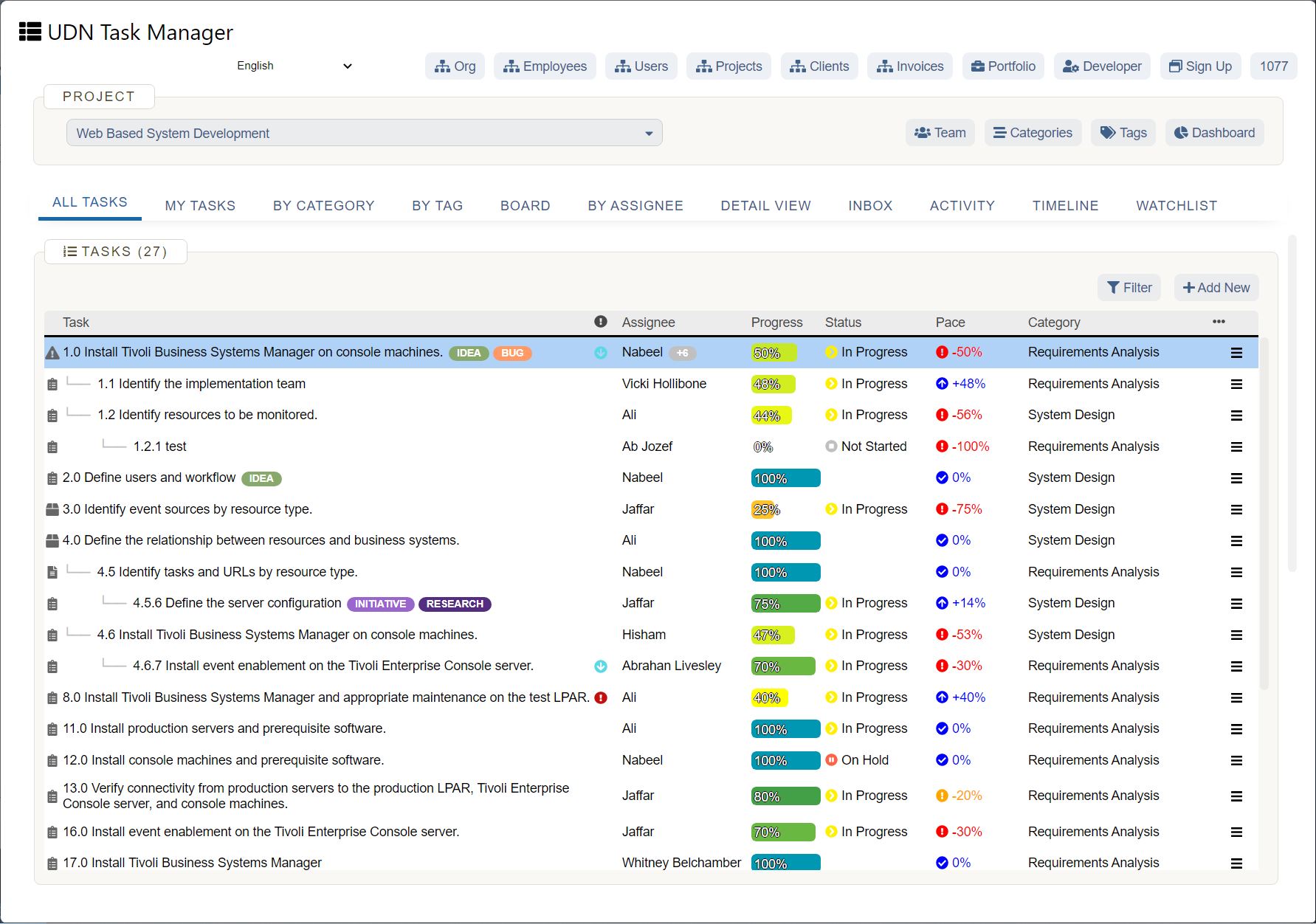

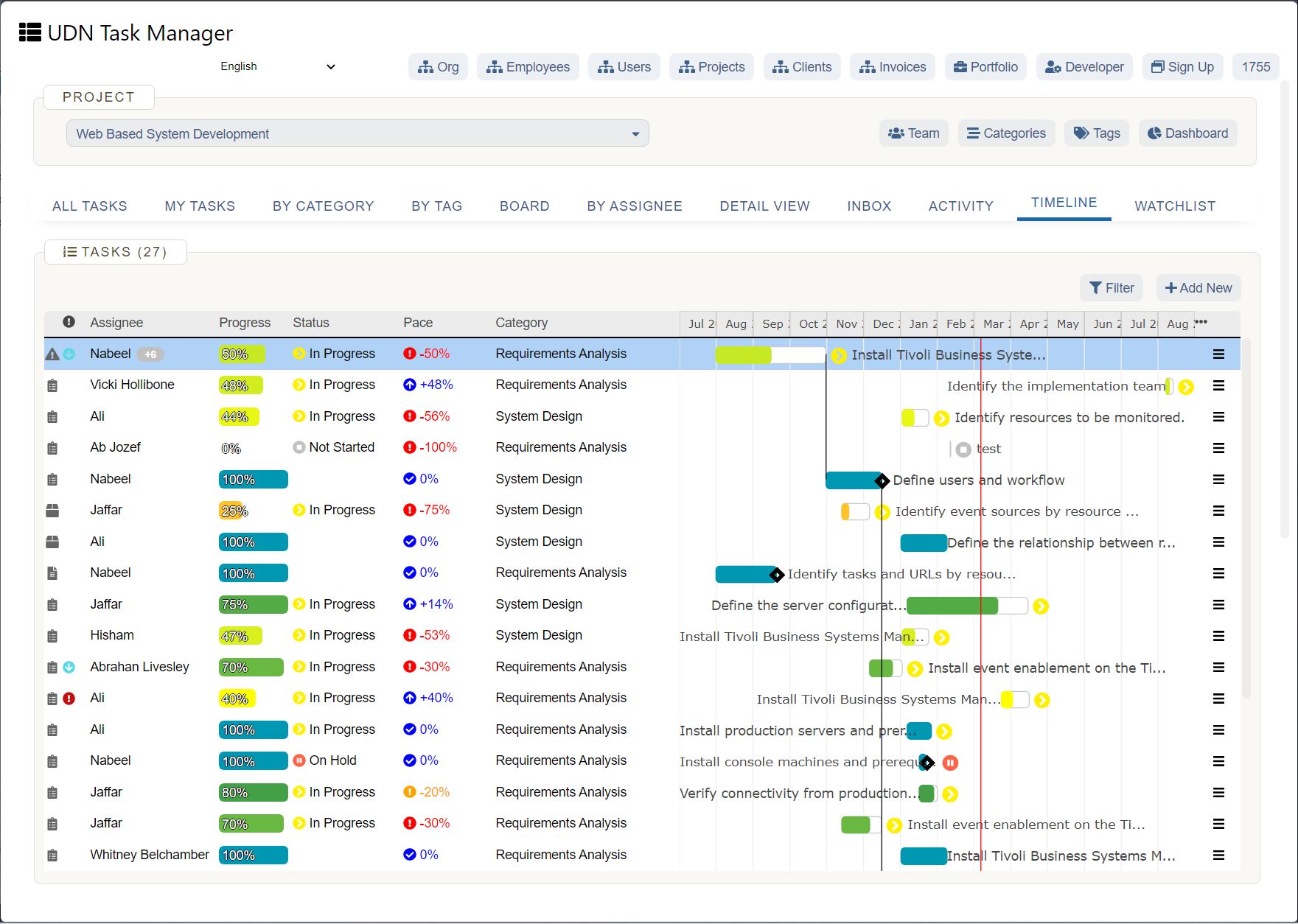

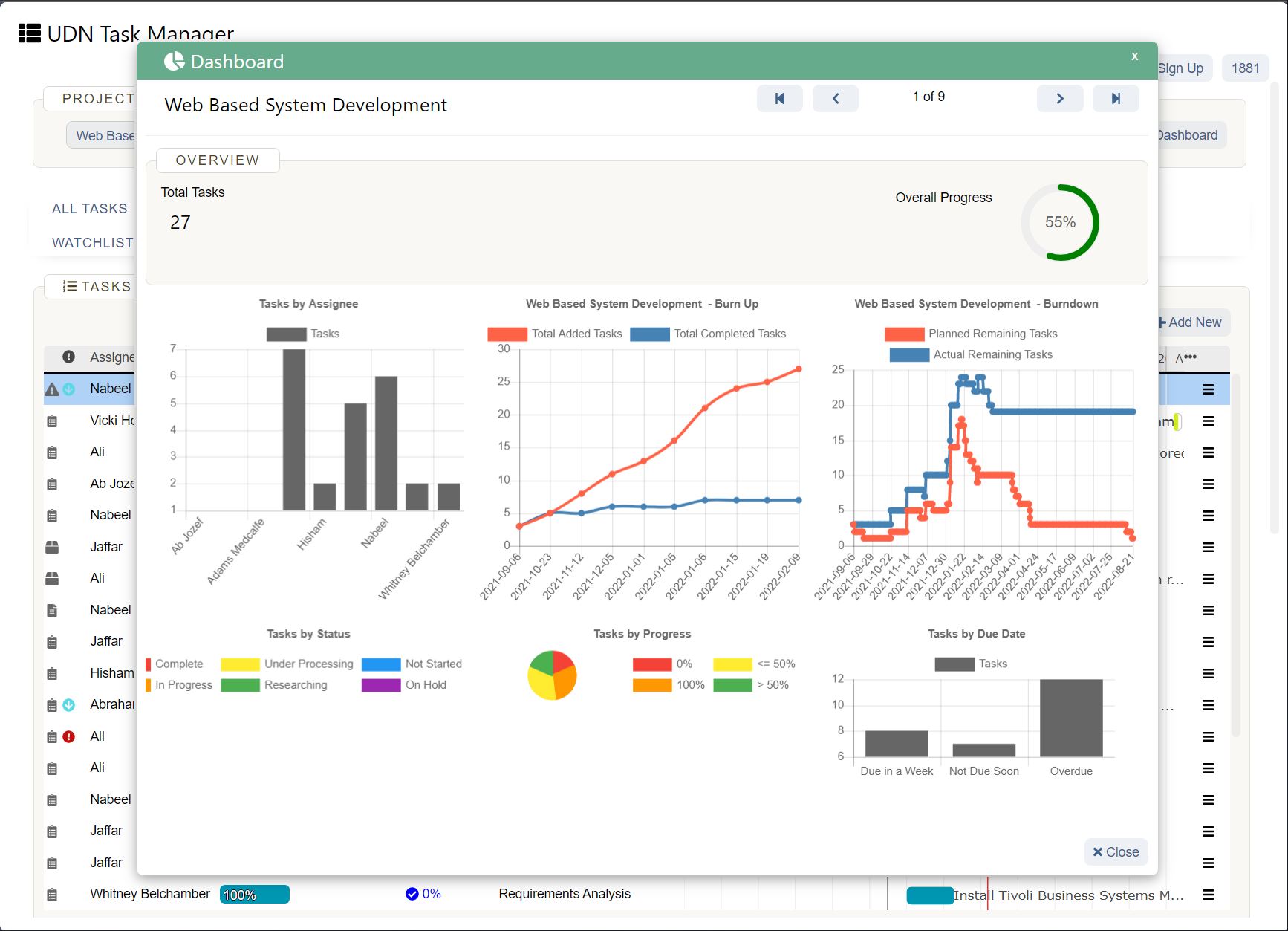

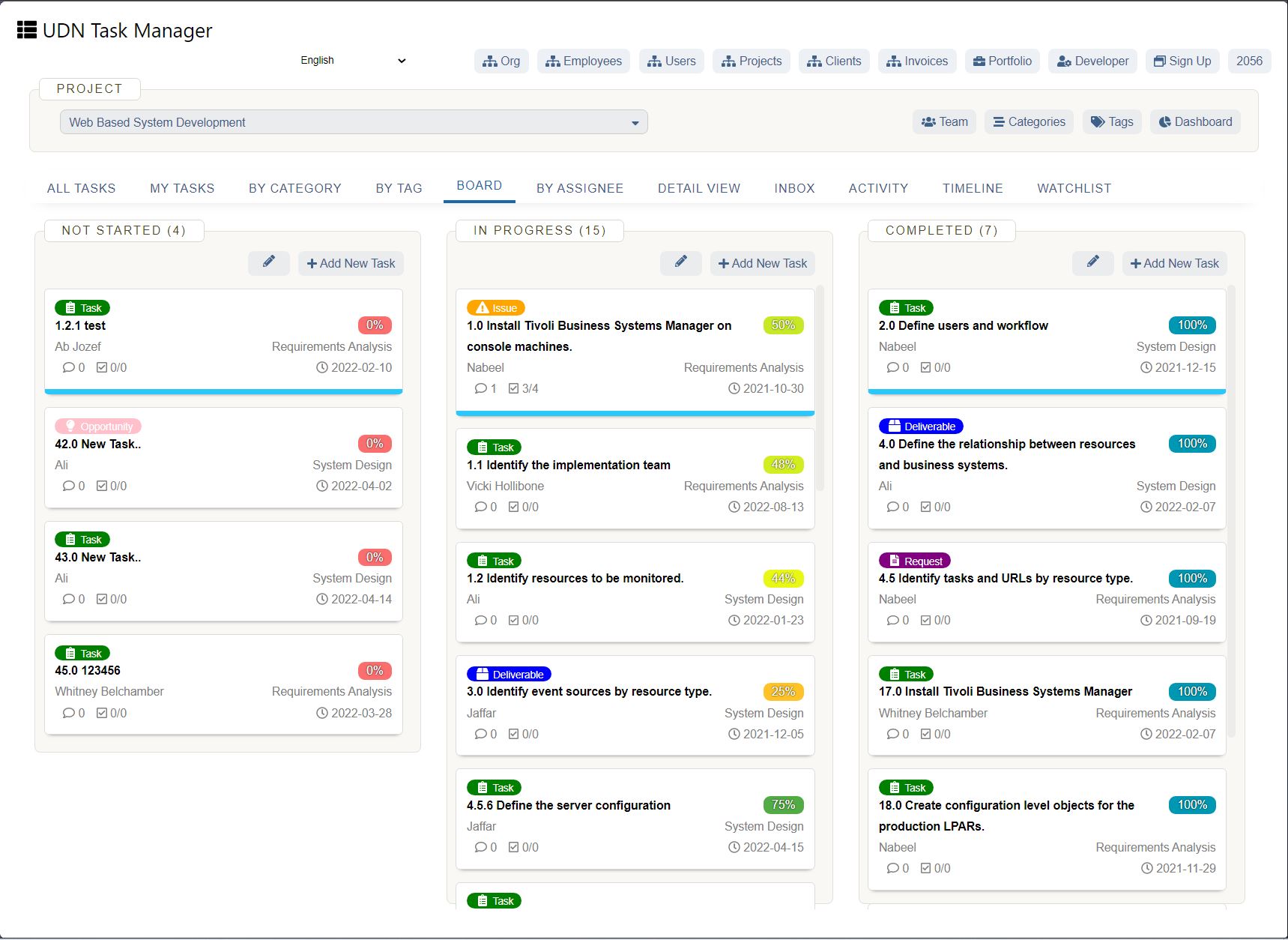

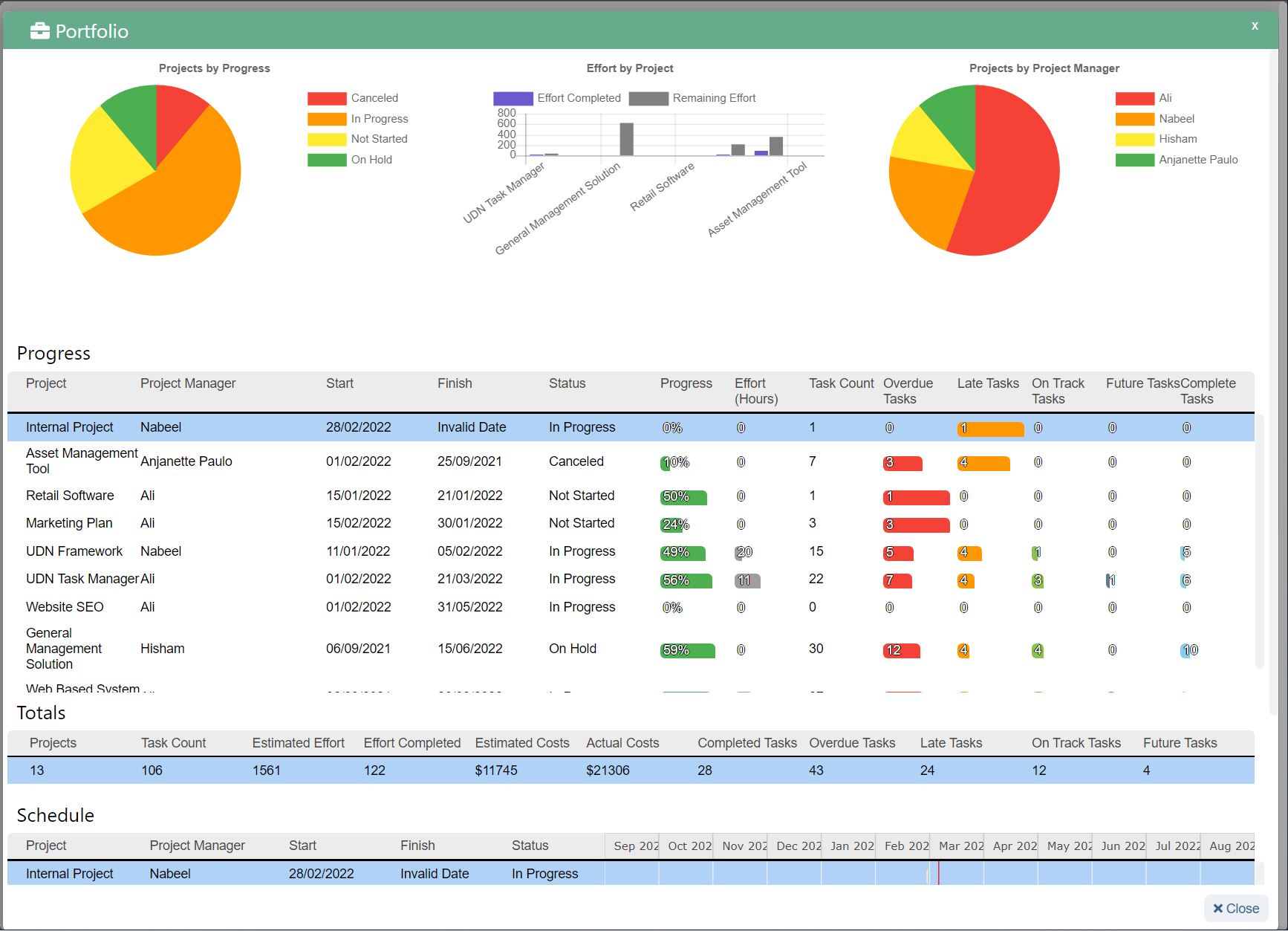

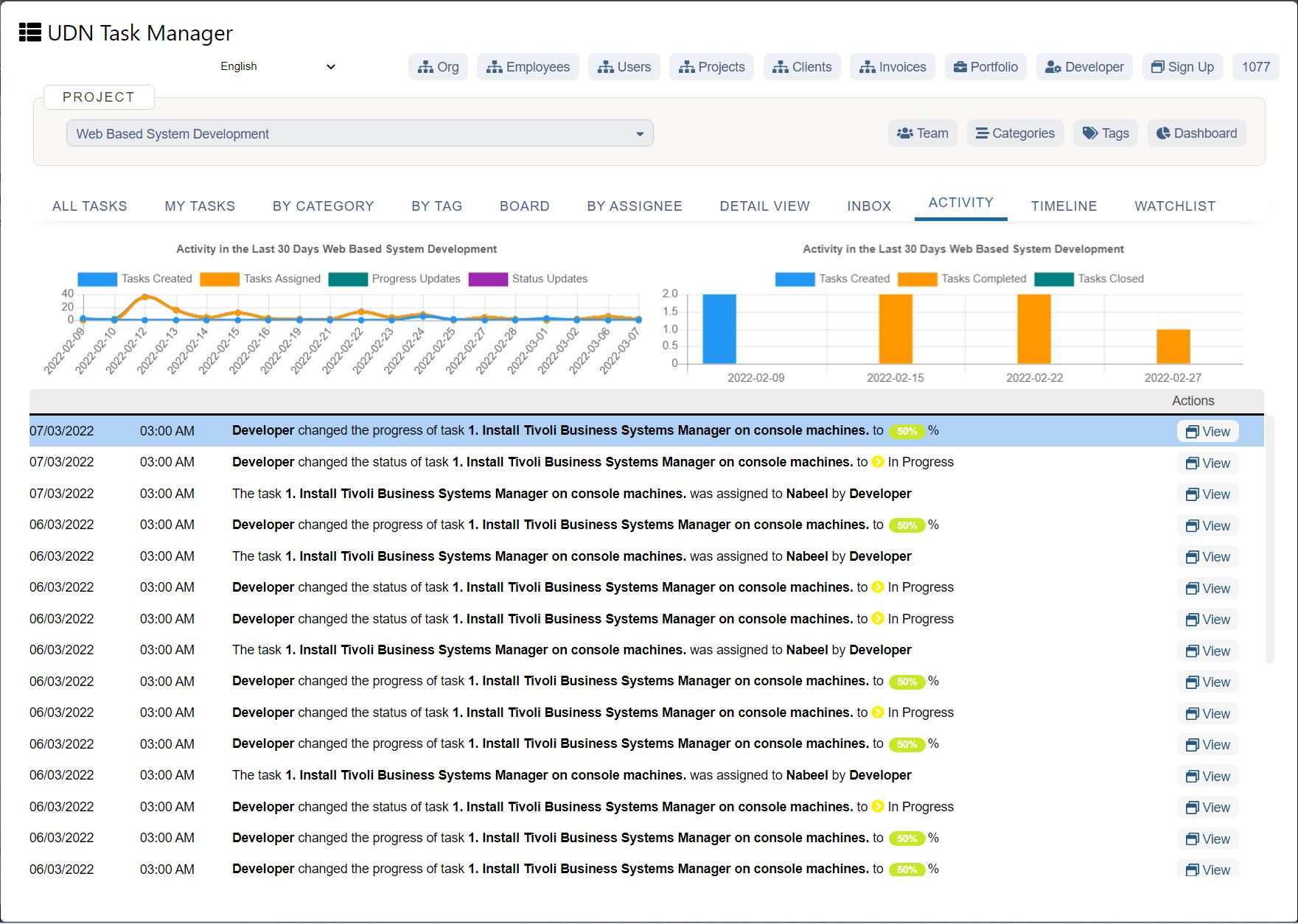

UDN Task Manager gives organizations unprecedented visibility into how their teams manage work and get things done, enabling companies to deliver consistent results and build operational excellence. We’ve also been building powerful automation tools and functionality that are enabling organizations to work more efficiently and drive results.

The best part? We’re just getting started.

Interested in learning how your organization can start implementing automation today? Download our new eBook to see the specific ways industry leaders like Airbnb, BMIND, Unbounce, and Esurance are using UDN Task Manager to automate their work, scale their output, and achieve more.

For further reading on automation, check out How Expert Project Managers Get Powerful Results with Automation .