PERT Guide For Project Managers and Productivity Gurus

PERT or Project Evaluation and Review Technique is a statistical tool that is used in project management to estimating the minimum time required for a project to complete by analyzing all the tasks required and by calculating the minimum time it would take to complete each task in the project.

The PERT chart is a crucial part of PERT methodology as it shows how to schedule, organize and coordinate tasks during a project. PERT Methodology allows the project manager to devise a budget depending upon the duration of the project without knowing all the details and durations of the tasks and to closely monitor the progress of the project. This methodology is favorable for projects where time is a bigger concern than cost, thus this methodology is a popular event-oriented technique.

This technique was devised by the U.S. Navy’s Special Projects Office in cooperation with the management consulting firm of Booz, Allen, and Hamilton when developing the Polaris submarine missile program in 1957. Thus, the technique is most suitable for large-scale, one-time, complex, non-routine infrastructure and Research and Development projects.

The 1968 Winter Olympics in Grenoble is an early example of the usage of the PERT technique. PERT was used from 1965 till the opening of the 1968 Games.

PERT is often mentioned in conjunction with the Critical Path Method (CPM) , a similar statistical method for forecasting progress which was developed by project management personnel in the private sector around the same time as PERT.

Although there are strong similarities between both techniques, they are complementary tools and are often referred jointly as PERT/CPM technique.

1. Identifying Activities and Milestones

Tasks and milestones are often written listed in a table in which information like sequence and duration is later added.

2. Determining Activity Sequence

This is a straight forward process for most project managers and allows them to efficiently employ project resources.

3. Construction of the Network Diagram

For complex and large projects, this phase is made easier by dividing the tasks into subtasks. This also makes it easier to manage large teams.

4. Estimation of Activity Times and Probabilities

PERT is used to deal with uncertainty related to activity completion times.

PERT is an ideal methodology for large and complex projects as it

Also Read:

The 33 Best To-do List Apps of 2022 for Personal Task Management

Like any technique, PERT is not without its limitations. Some of its limitations are as follows:

Time is the only variable. The effects of resource and technical performance changes enter into the analysis only regarding their effect on elapsed time for the affected activity (Monte Carlo has a similar limitation).

The potential range of outcomes for any activity can vary depending on the type of work contained in the activity. PERT is limited to the single ‘Modified Beta’ distribution, modern systems allow a range of different distributions to more accurately reflect the variability inherent in each activity.

Triangular, Normal (Gaussian), Beta, Flat (no preference for any value between the max & min) and customizable distributions to name a few. This limitation in PERT reduces the accuracy of the calculation. The Calculation for SD is an Approximation. The PERT calculation for the value of the SD is a significant source of error. Modern computers can easily manage the more complex calculations needed to accurately assess the actual SD for a data set.

The single-pass PERT calculation generates a single value. Techniques such as Monte Carlo run many hundreds of simulations that generate significantly richer and more accurate information.

The single-pass PERT calculation based on the ‘critical path’ ignores the possibility that other sub-critical paths may take longer to complete under certain circumstances. In the sketch above, if the critical path is achieving an outcome close to its ‘most likely’ date, but the sub-critical path is heading towards a pessimistic outcome, the project completion will be delayed, but the PERT calculations fail to recognize this.

The adaptability of PERT means that it can be implemented for many projects. PERT can be used for a variety of projects, including the following types.

PERT can be adapted and used for a variety of projects. However, by its very nature, PERT is used for projects where estimating the time required for each task and the whole project involves some uncertainty.

The development of PERT was born out of sheer necessity. In 1956, the U.S. Navy’s Special Projects Office was working on the Polaris missile development program. Concerned with the Soviet Union’s growing nuclear arsenal, U.S. Navy wanted to speed up the process, however, they discovered that all the conventional management methods were inadequate for handling such an immense project.

U.S. Navy’s Special Projects Office helped by the Lockheed Missile Systems division and the Consultant firm of Booz-Allen & Hamilton devised PERT to address the issues faced by the Polaris missile development program. The solution was devised keeping in view the uncertainty involved in coordinating the efforts of 11,000 contractors. The methodology was developed keeping in view time as the critical factor.

The calculations were so arranged so that they could be carried out on the IBM Naval Ordinance Research Computer (NORC) at Dahlgren, Virginia. The methodology was so successful that it is attributed to the completion of the projects two years before the original estimate. The success of this application led the U.S. Department of Defense to specify that all future defense contracts must use PERT.

In 1991, the Persian Gulf War is well underway. General Schwarzkopf directed that the logistics community keep a 60-day supply of material on hand which included medical supplies, fuel, etc. Conservative medical supplies estimates alone amounted to 26,352 short tons. The combat unit was designed for mobility and survivability and thus carried only two-day supplies on missions. They relied heavily on a steady source of new supplies.

The Solution

Using PERT, resupply technique was optimized in such a way that the optimized the resupply time from 6 hours to 3 hours and allows both the supply team combat unit to be on the move during resupply activity. This helped increase security, and supply vehicles make more round trips in the same amount of time. This also gave greater freedom to the tactical commander in planning as less time was taken up by resupply activities.

Brief Description

Planning and implementing transcutaneous pC02 monitoring developed as a new clinical service by the Department of Laboratory Medicine at the University of Washington using PERT.

Actors

Precondition

Requirements

Basic Flow:

Ø Select premature infant for study

Ø Get consent from parents to participate in the study

Ø Take temperature

Ø Record temperature

Alternate flow

Ø Parents volunteer themselves

Exception flow

Ø No premature birth

Ø Refusal

Ø Problem taking the temperature

Ø Time Crunch

Ø Inaccurate estimates

Brief Description

Planning and development of an advanced navigation system using PERT.

Actors

Precondition

Basic Flow:

Ø Set up meetings with relevant stakeholders

Ø Start discussions on the basic requirements

Ø Elaborate and improve understanding of the requirements

Ø Finalize requirements

Ø Document requirements

Ø Send for final approval

Ø Get approval

Exception flow

Ø Disagreements resulting in a delay in gathering requirements

Vlaamse Maatschappij Voor Watervoorziening (VMW) , a Flemish water distribution company, used PERT on a project at the water production center (WPC) of Kluizen, Belgium. This center produces and delivers water by transforming surface water into drinkable water. It then distributes it to the customers by taking several different steps.

The VMW project was aimed at expanding the production capacity of water in East Flanders to address scheduling problems. It was a very capital-intensive project with a duration of more than six years.

The subproject extension of the storage capacity of treated water requires building two extra reservoirs for treated water (RWK). This will allow WPC to meet the daily demand of the customer.

To increase the storage capacity of pure water, VMW built two new reservoirs, each with a capacity of 15,000, installed pumps in a new high-pressure room to assure the circulation of the pure water, installed new high voltage cabinet for the increased energy requirement and built pipes between these new installations. With the help of these new reservoirs, they were able to satisfy demand during peak hours.

Using PERT, VMW was able to calculate the duration of all 26 individual tasks required for the completion of the subproject. PERT helped them in better scheduling of tasks and managing project deadlines by giving special attention to tasks on the critical path.

Dishansh 2005 is a software that calculates spatial relations by plotting planer and linear structural features, for seismological and geotechnical interpretations. Dishansh 2005 development team used PERT for planning, scheduling, and control of activities during the software development process. PERT was used as it allowed analysis and visualization of structural data following the same technique used in manual stereo nets.

PERT allowed the project managers to calculate the time required for the development of the software with some certainty. It also presented all the tasks in a logical manner and the duration required for the completion of each activity. Network diagram was constructed and the critical path identified. With the help of PERT methodology, Dishansh 2005 was able to predict that the probability of project completion within 60 days was 99.77%.

As business varies according to type, size, industry, and many other factors, so do projects. Rather than looking for the best methodology, businesses should learn these methodologies, their uses, and applications and decide upon the best methodology for them according to the following variables:

PERT Methodology was designed for large, and complex projects. It is the preferred method for projects when time is of the essence but calculating it involves uncertainty. By its very nature, it is suitable for projects that are perhaps not very common or consists of large complex activities.

The PERT Methodology helps project managers make sense of complex procedures, that might involve activities that they are unfamiliar with. Alternatively, it can help to graphically organize tasks and activities.

If your entire team is working on a large multi-faceted project, PERT will help in the visualization of the order of tasks, milestones, and phases within a project. This will help you coordinate work across teams and departments more effectively by identifying the nature of the tasks: dependent, or sequential tasks or non-dependent, or concurrent tasks.

Table 1: PERT Checklist

PERT Checklist

Project management methodology is vital for today’s businesses. By using an appropriate style for your business, you can transform the way your team collaborates, works on tasks, and accomplishes project milestones.

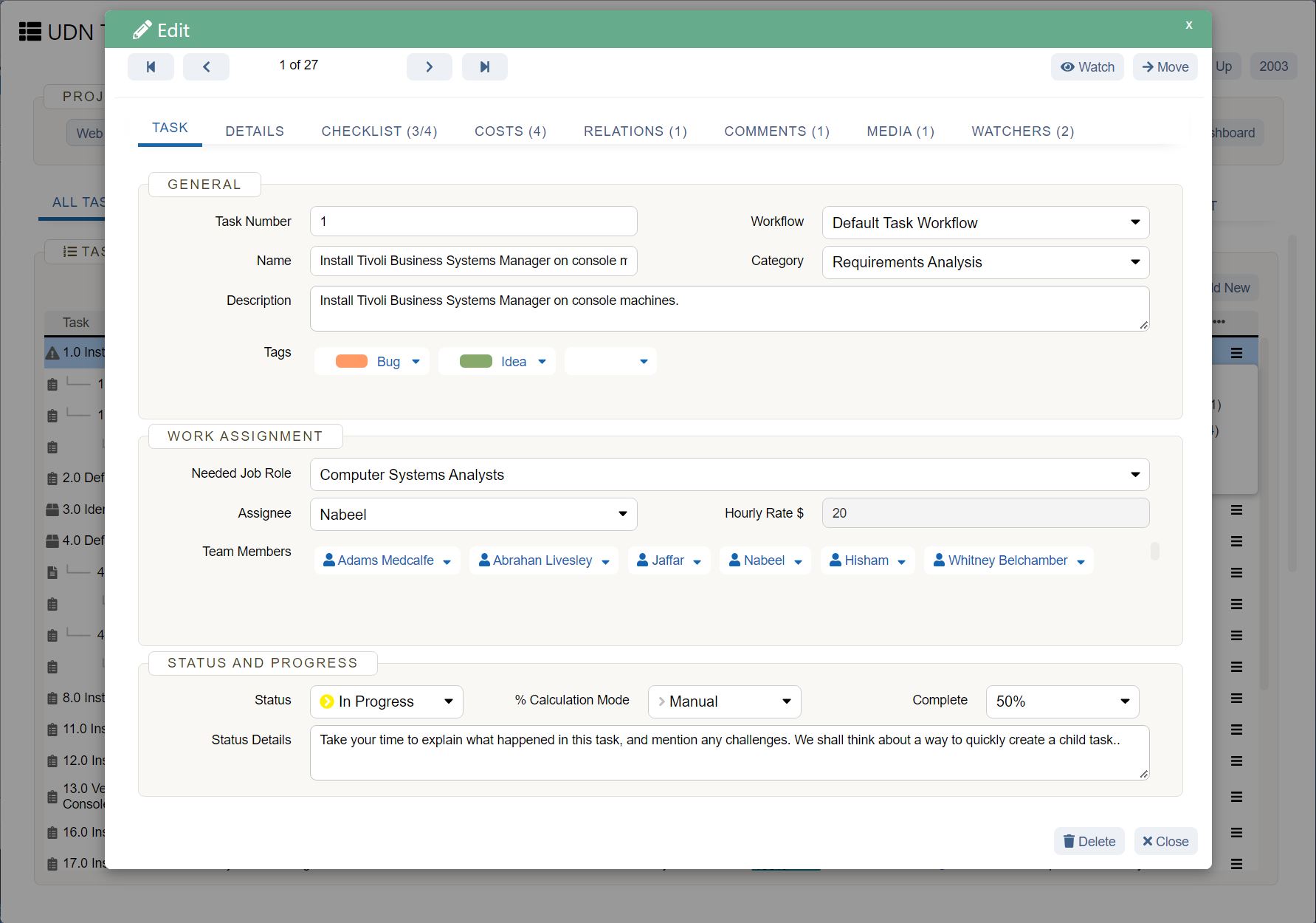

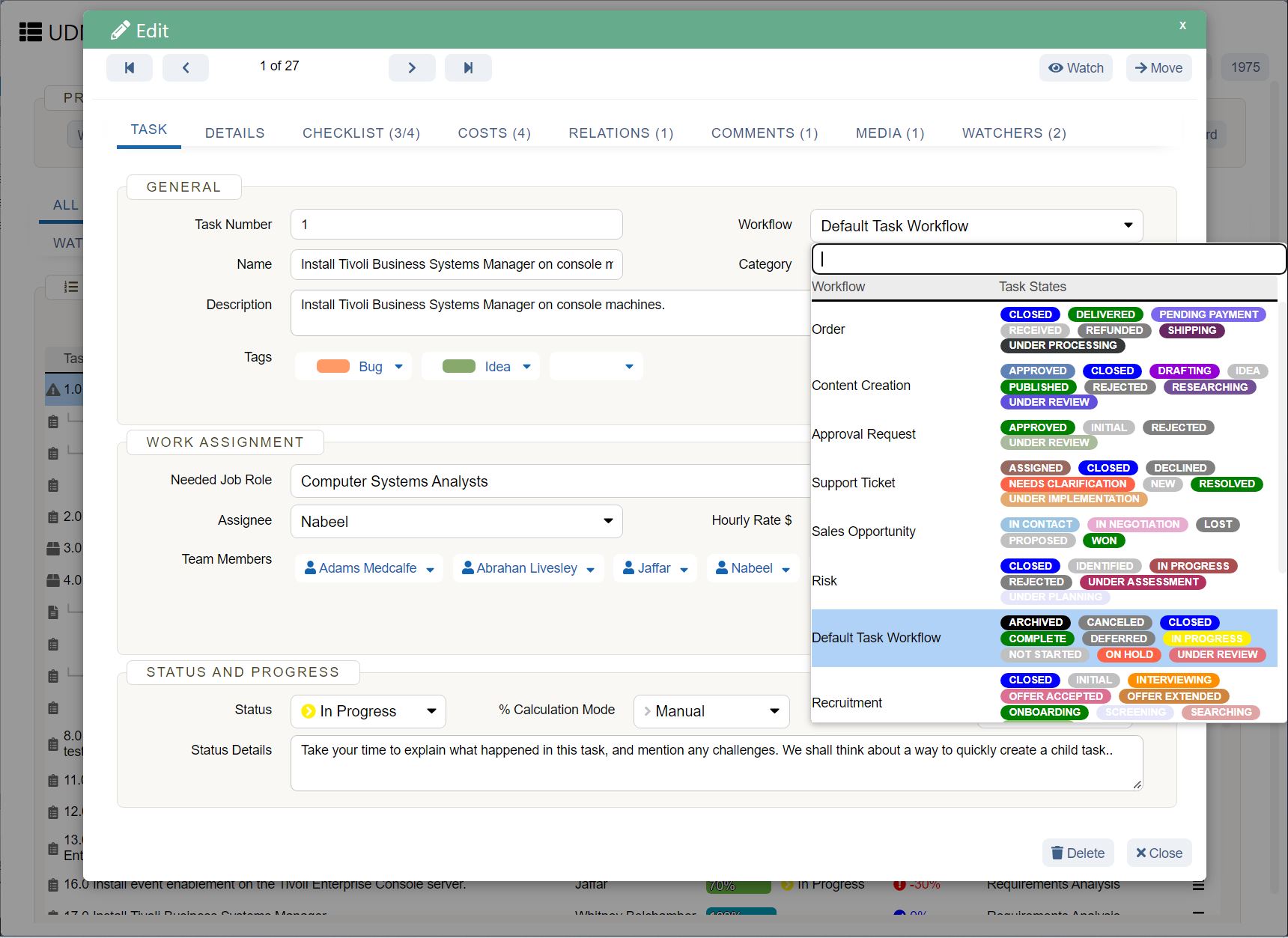

UDN Task Manager and PERT

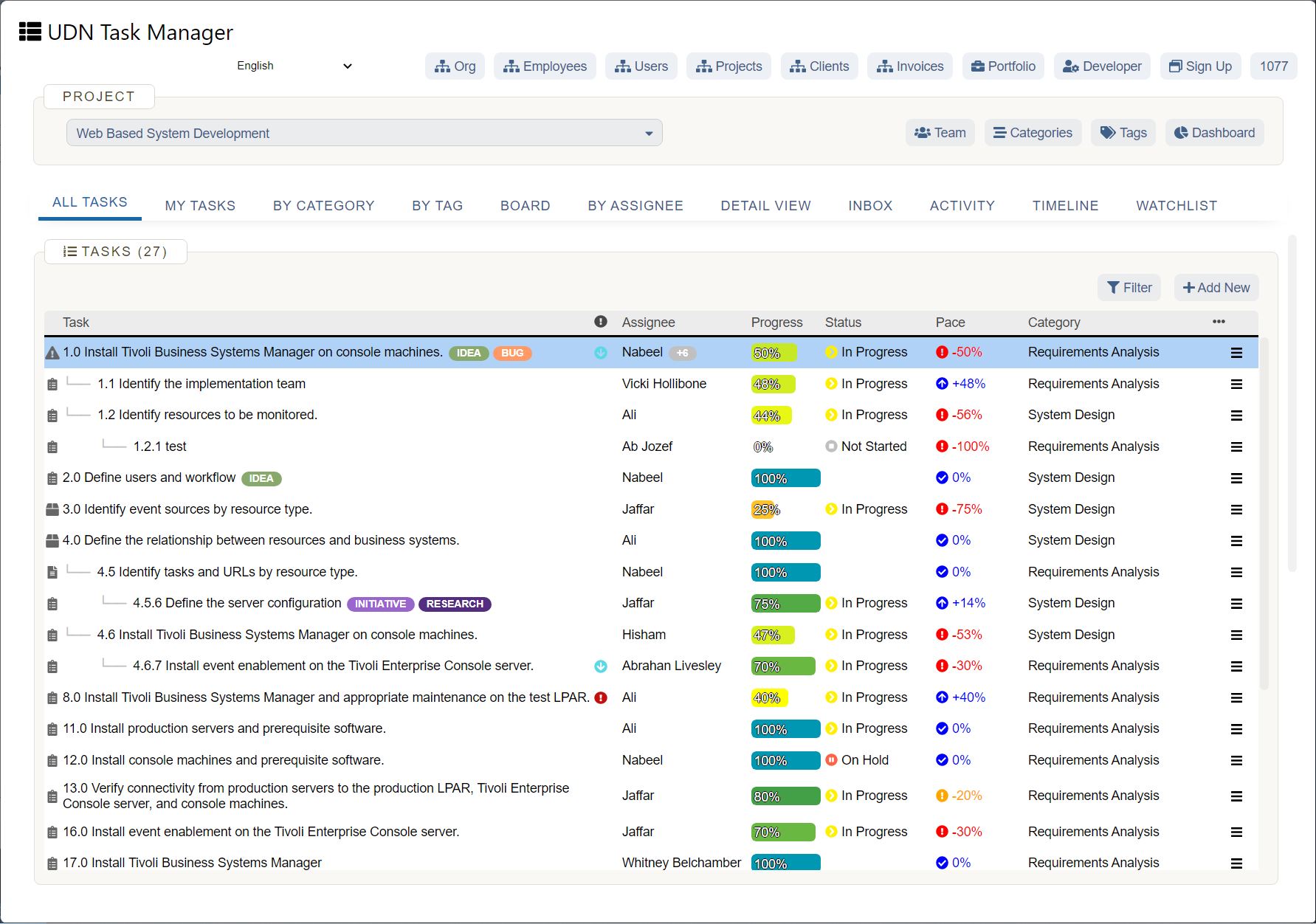

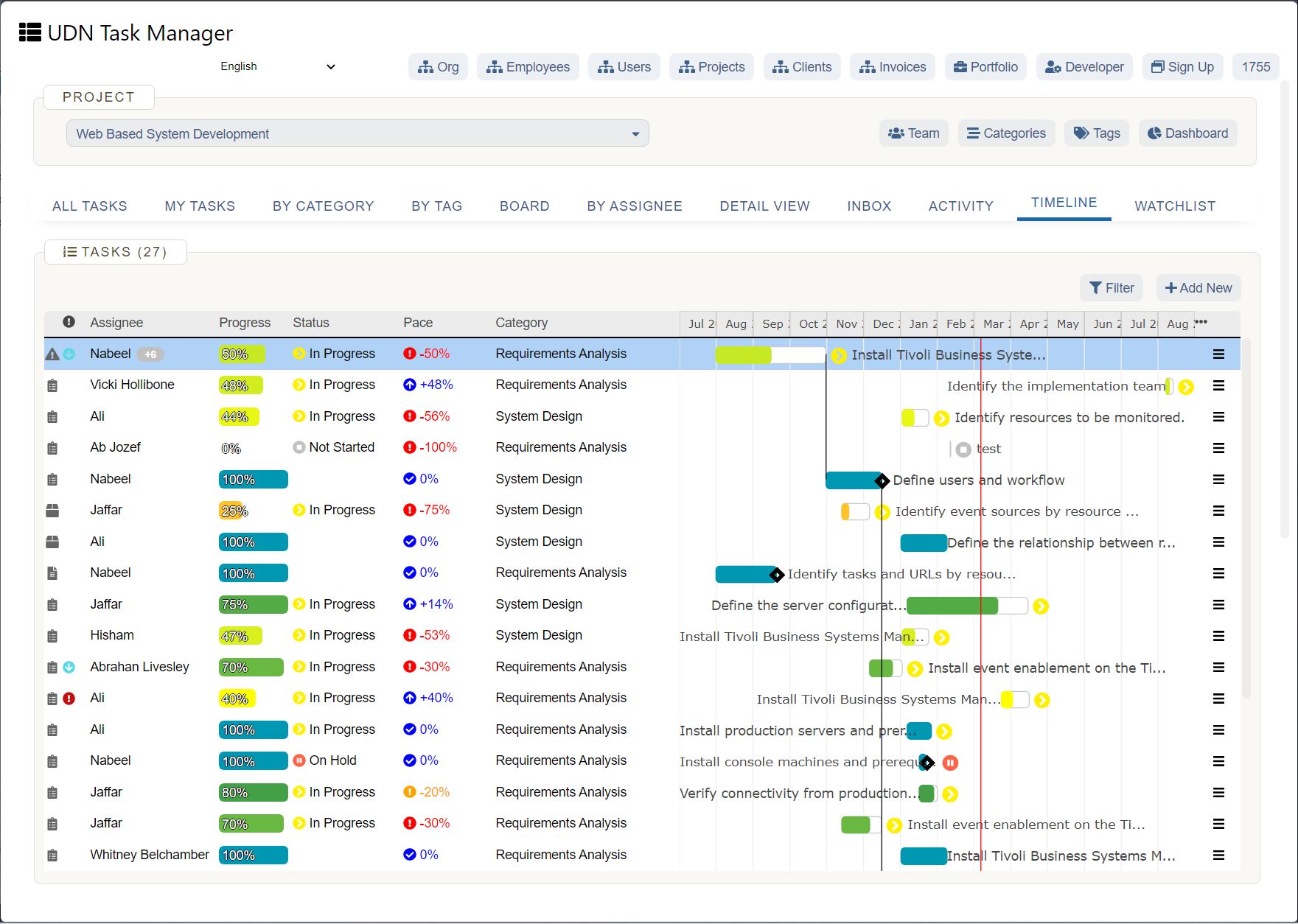

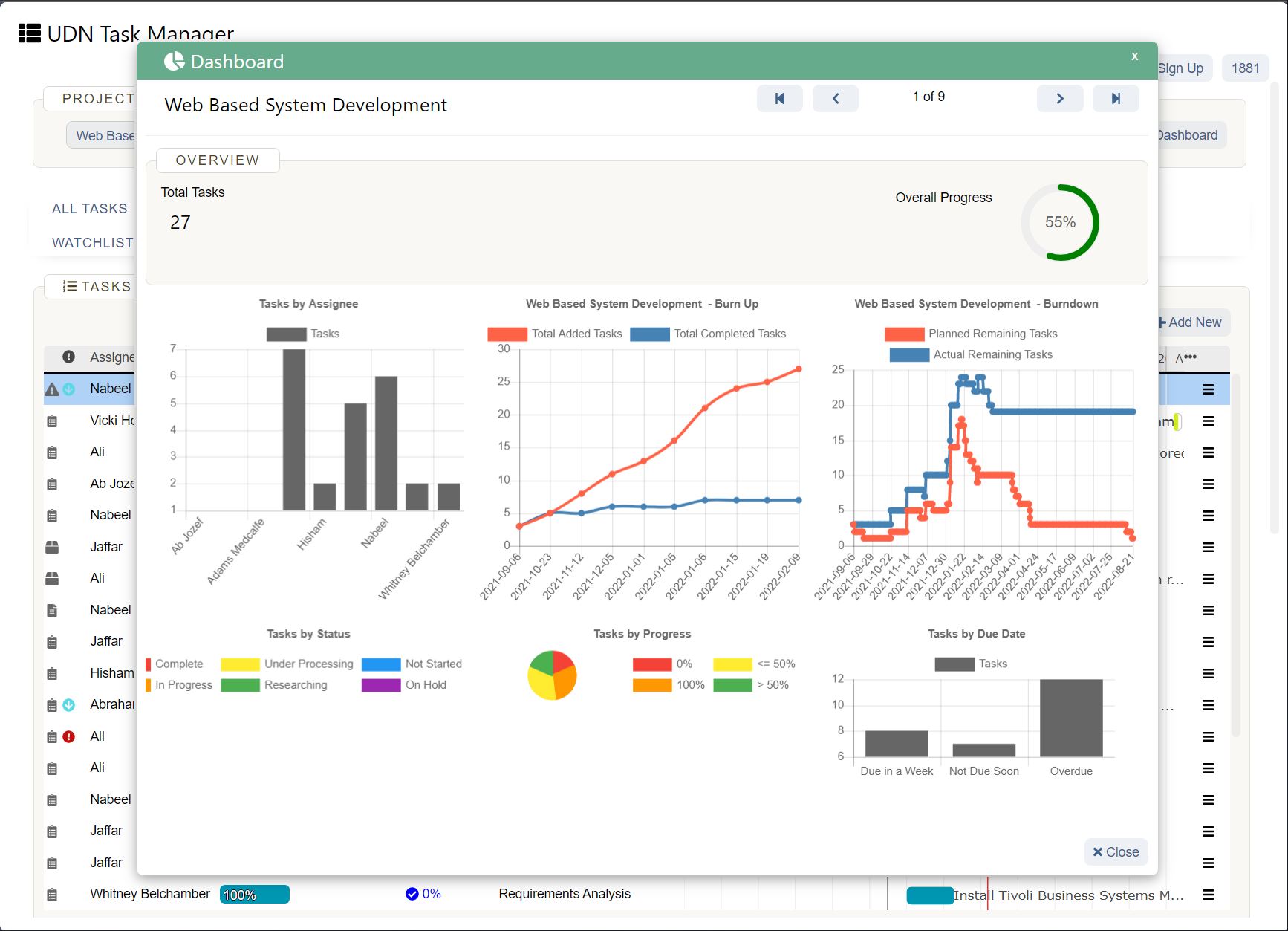

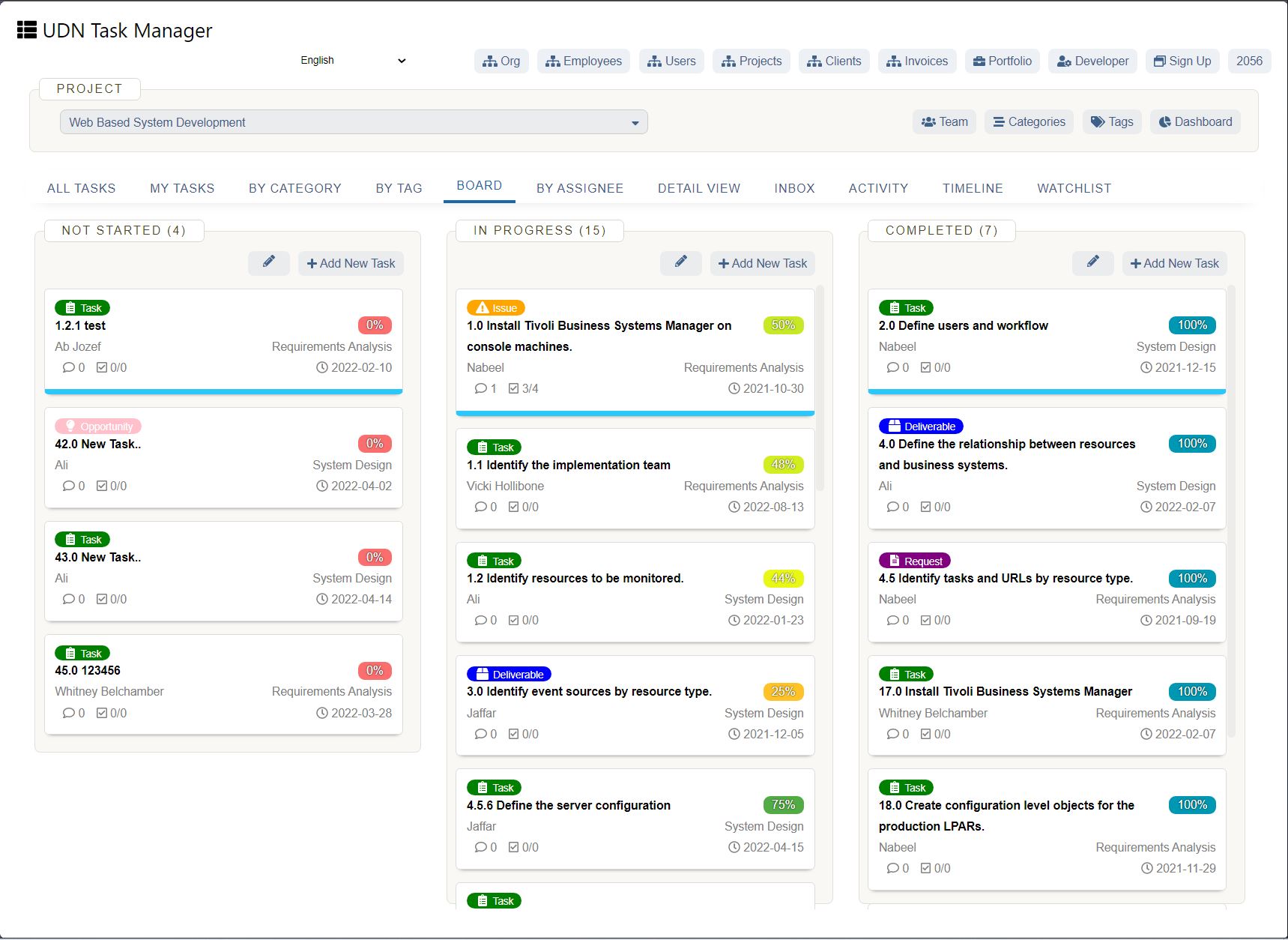

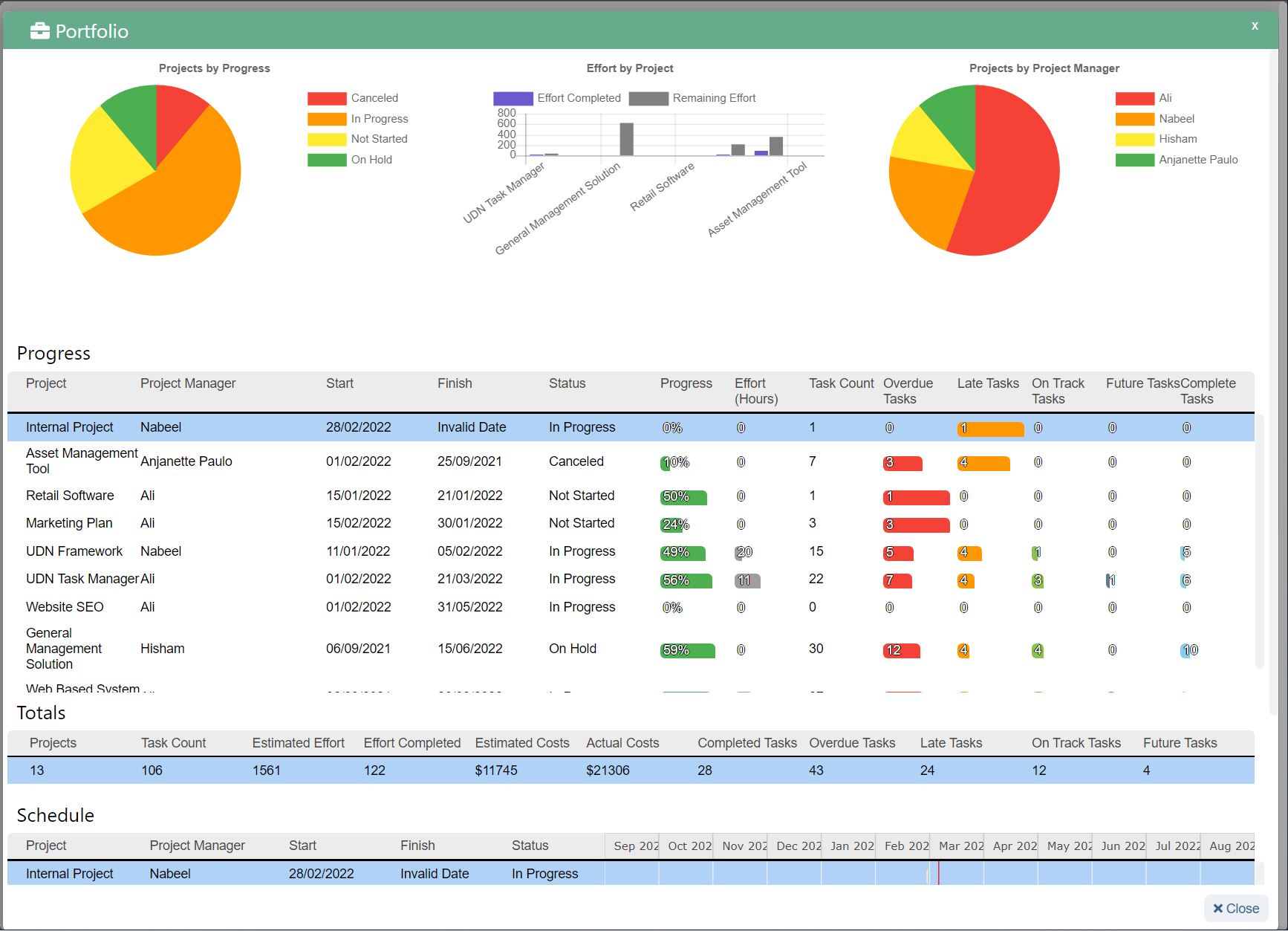

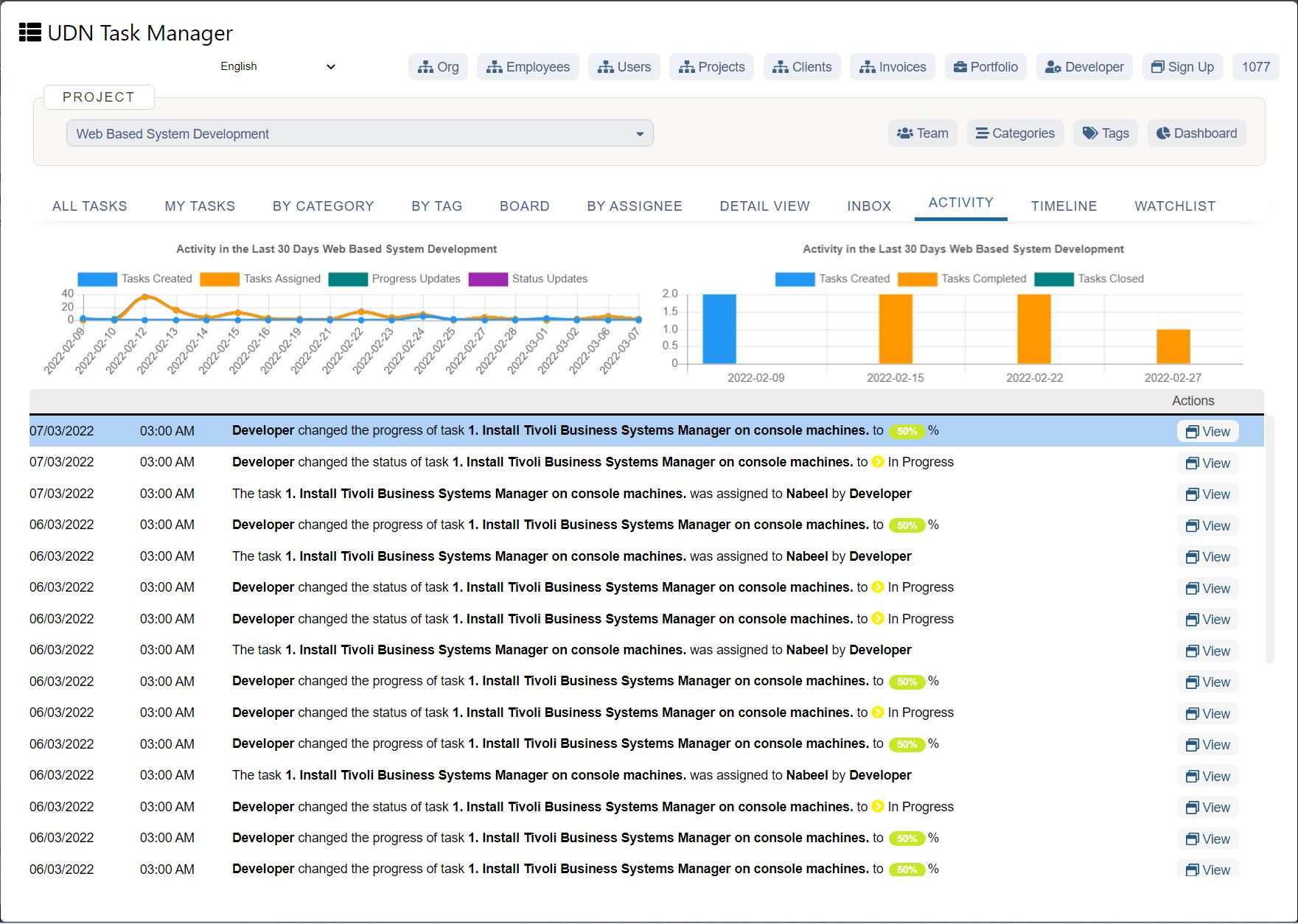

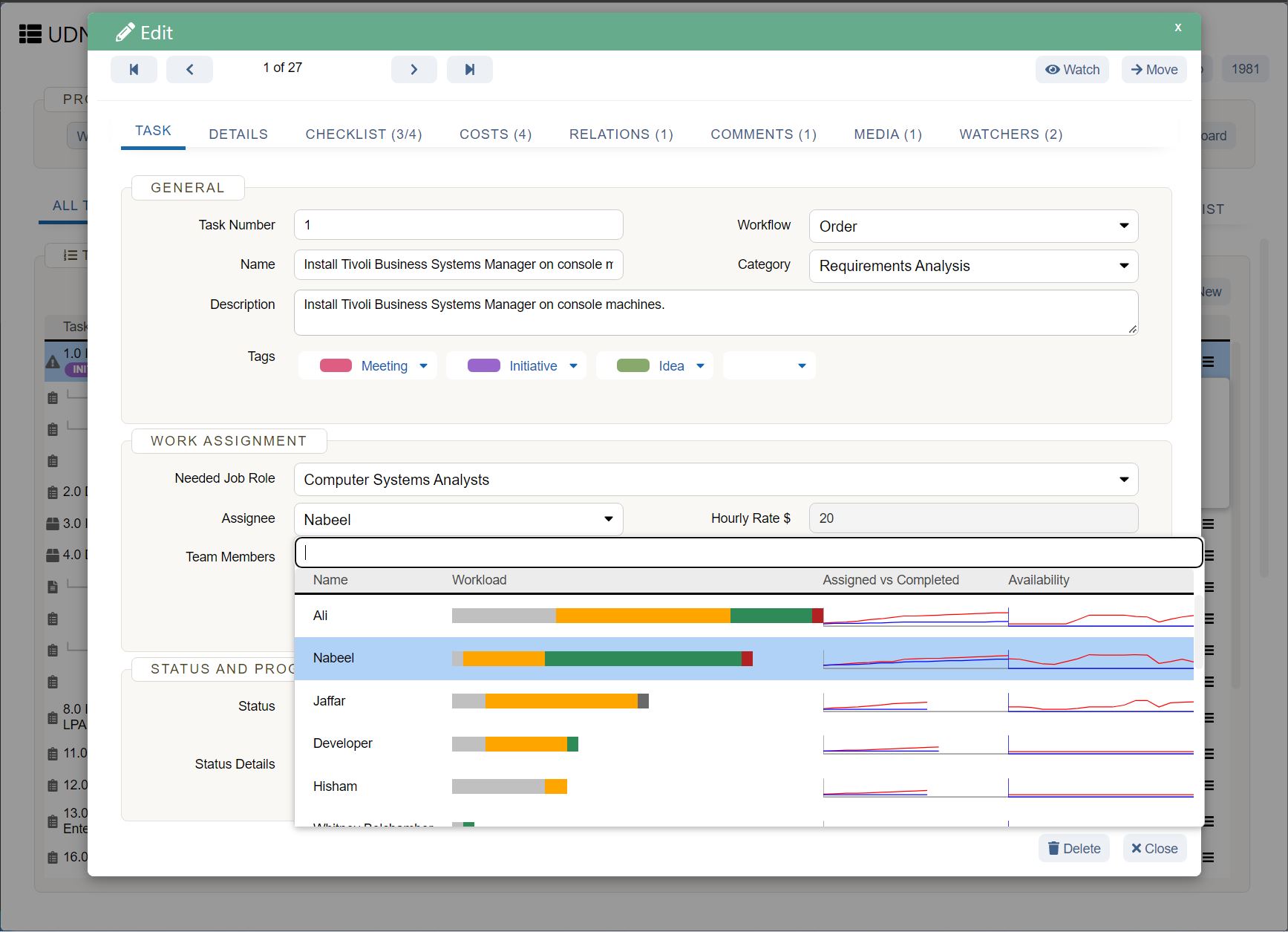

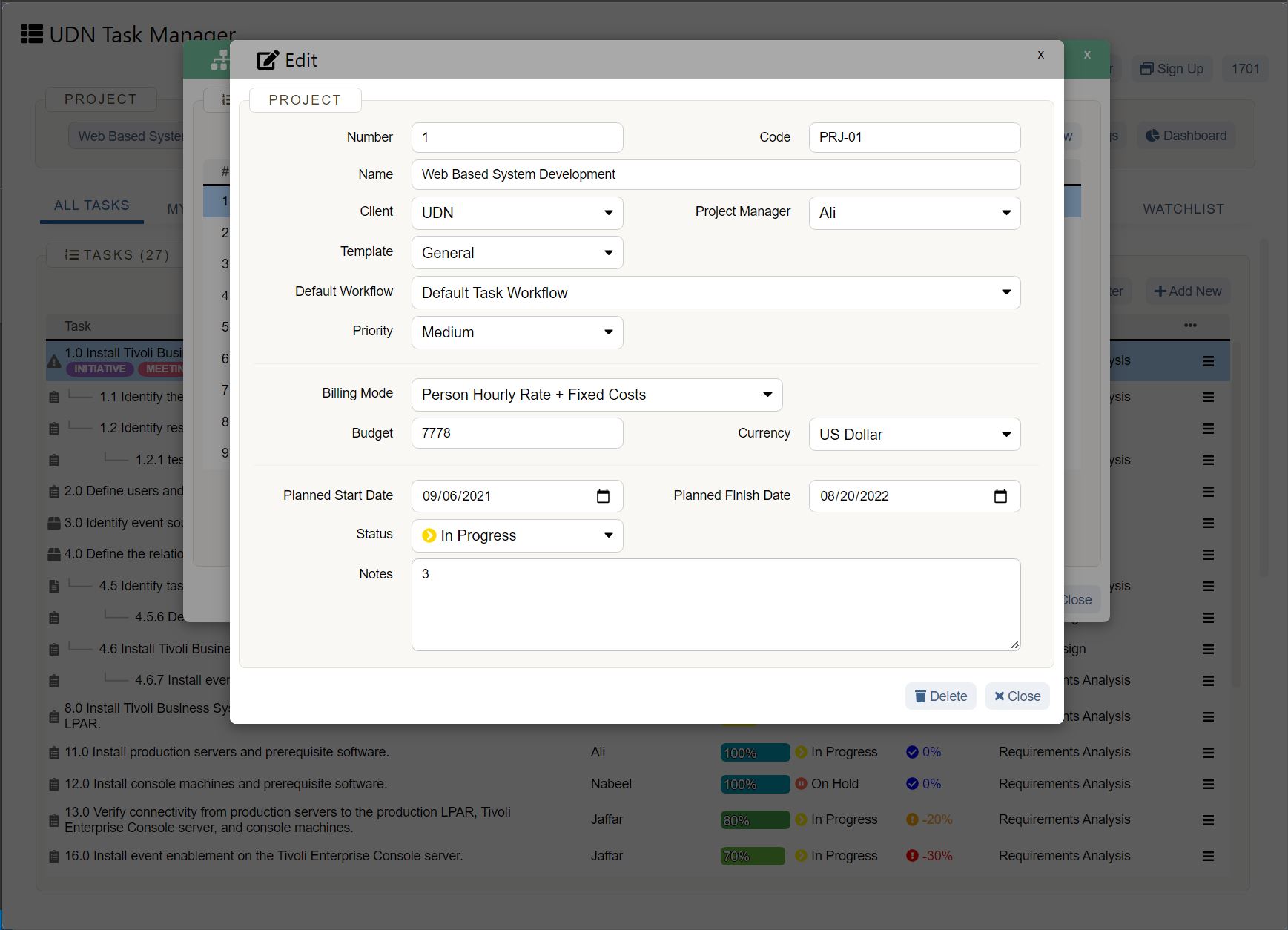

Even with the help of PERT, project management can be overwhelming. For large and complex projects any miscalculation or accidental omission will leave you bewildered. Using project management software like UDN Task Manager will ensure that you will not get overwhelmed by the size or duration of the project.

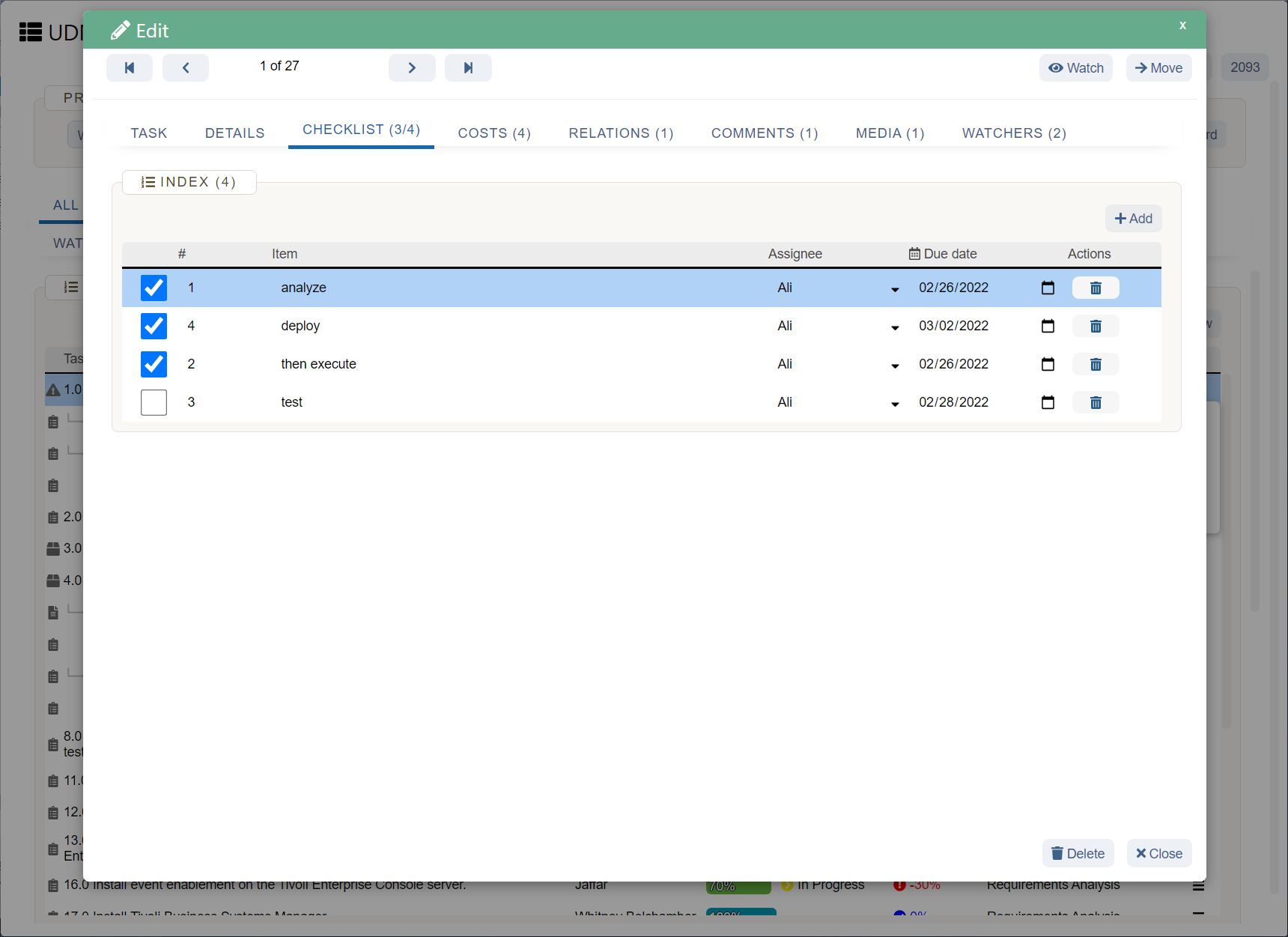

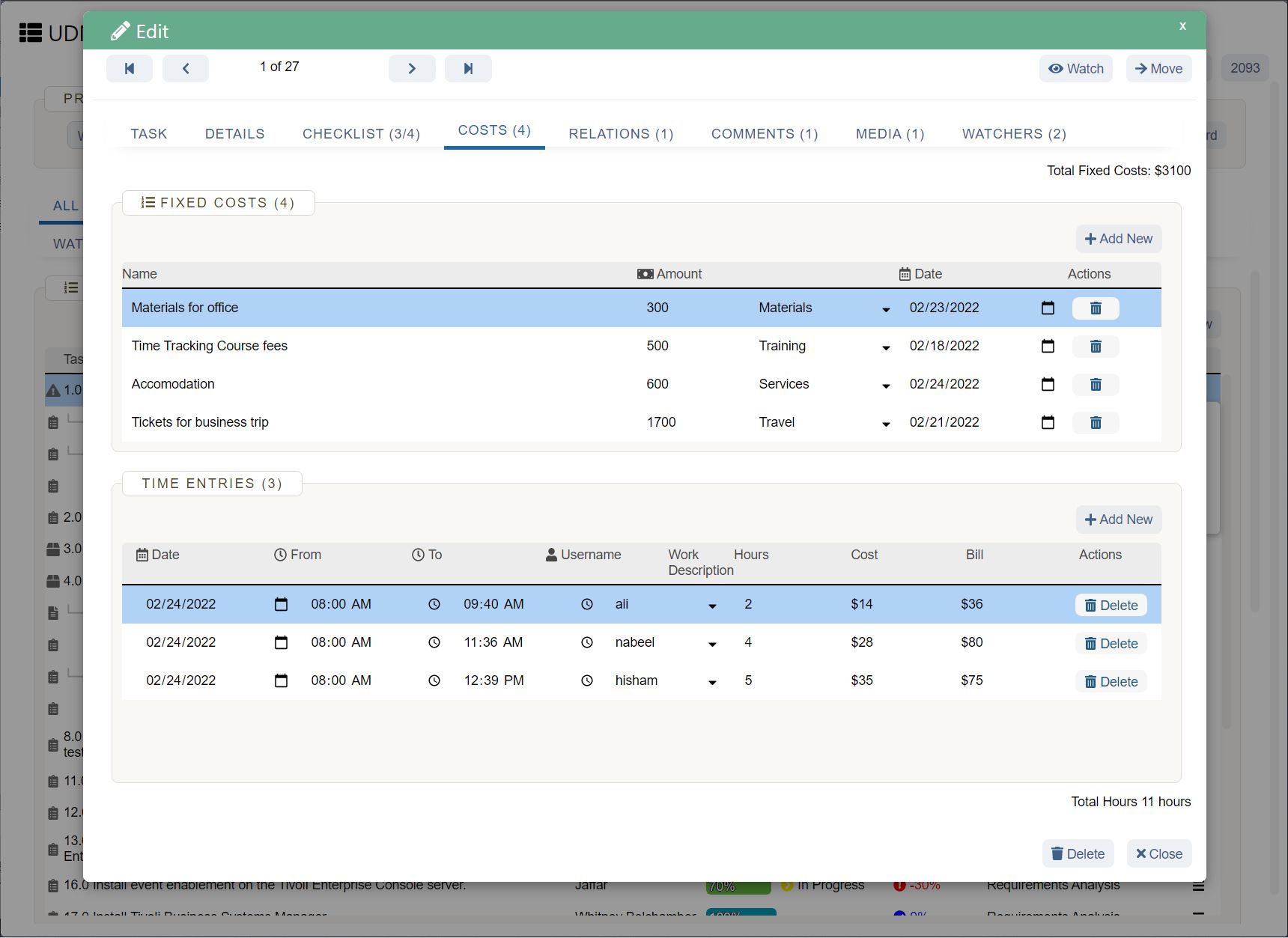

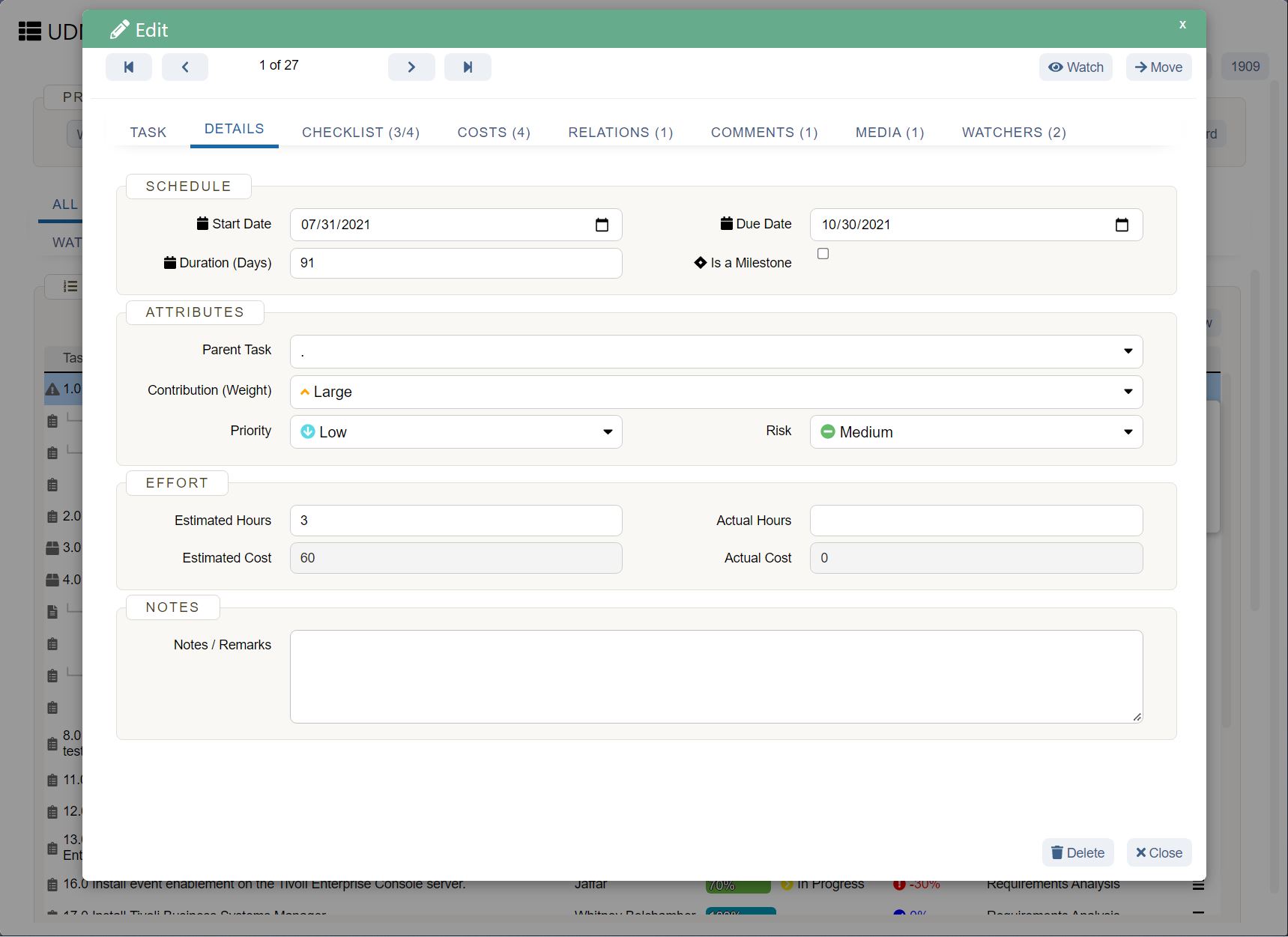

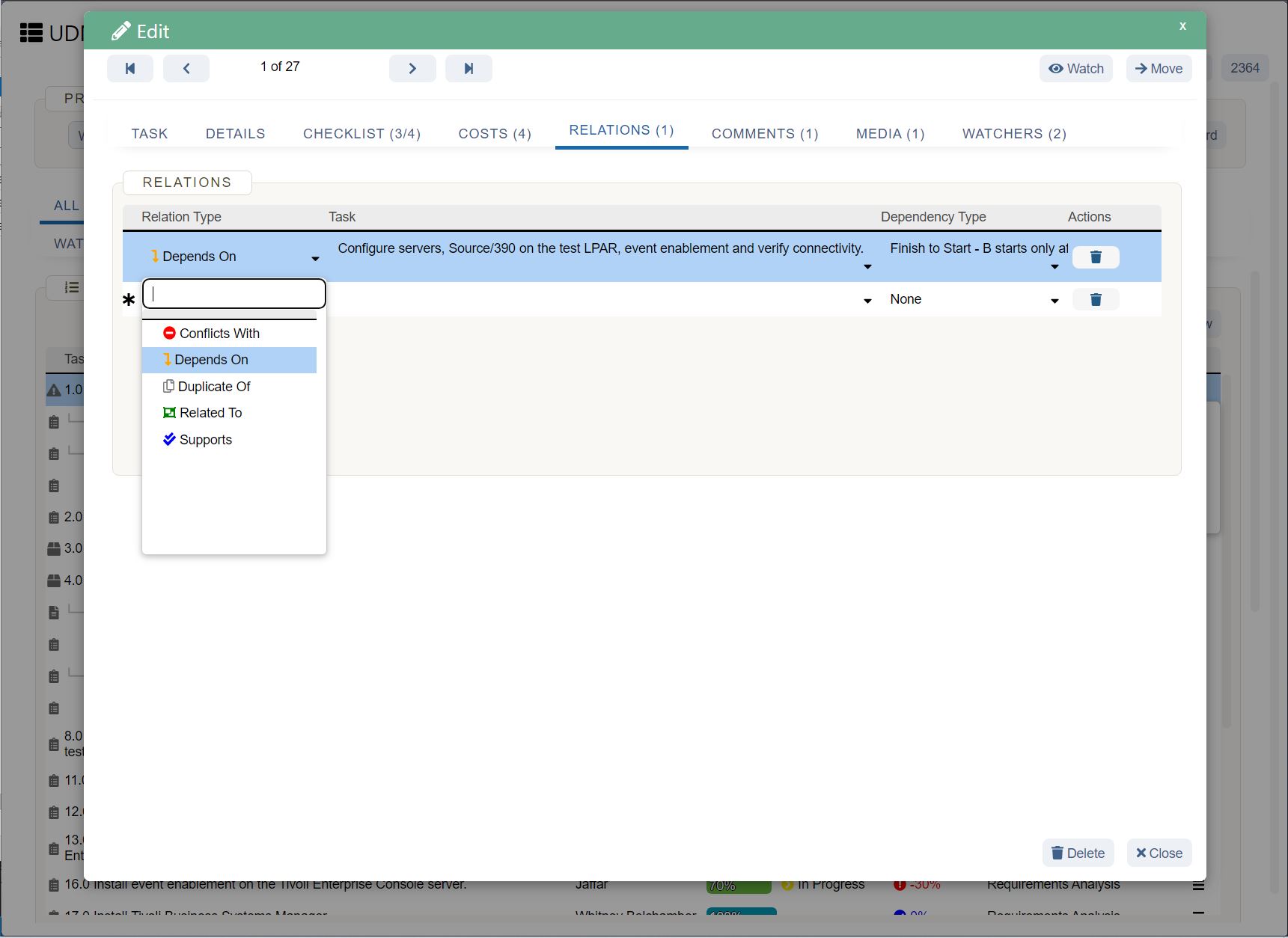

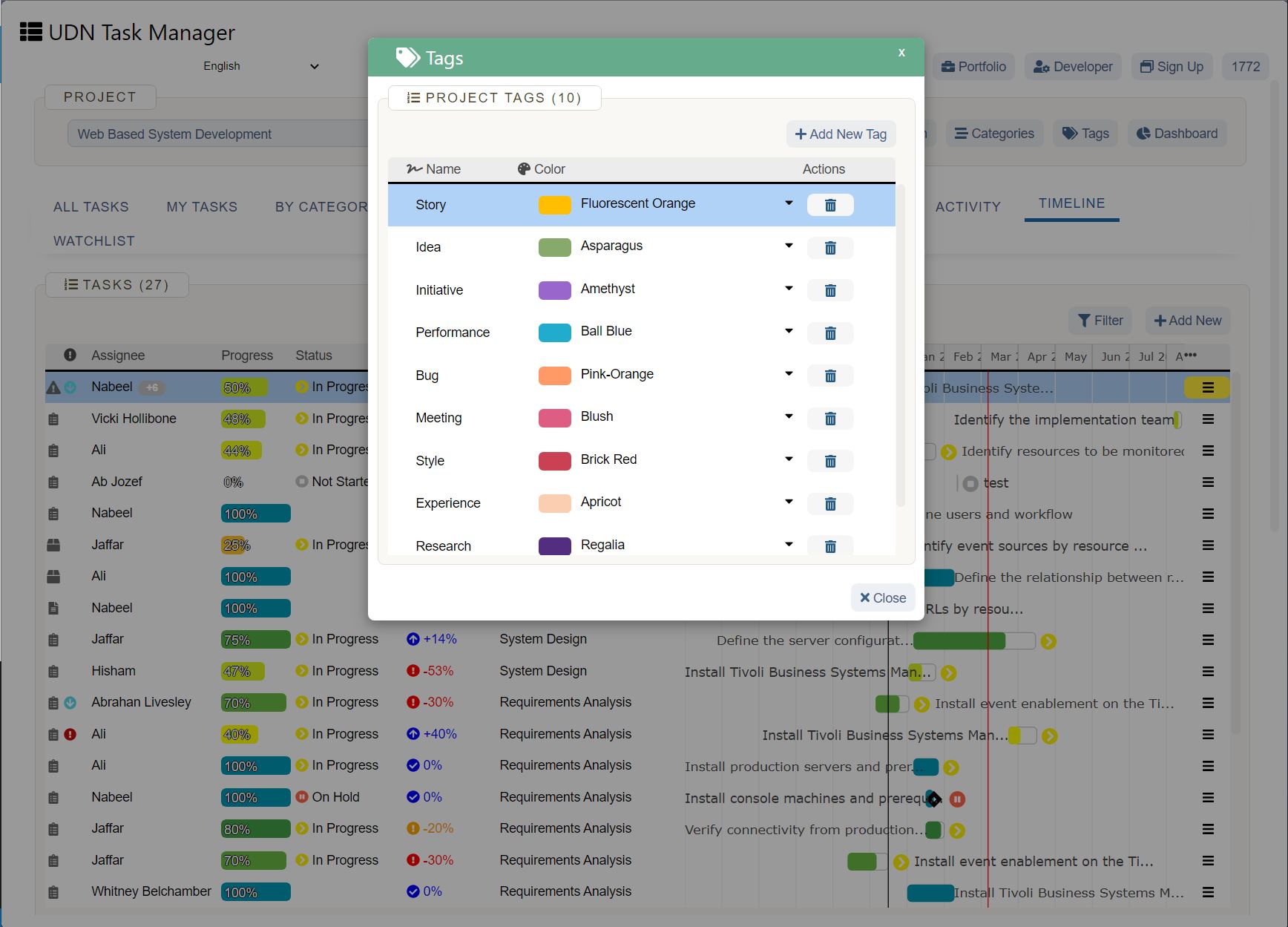

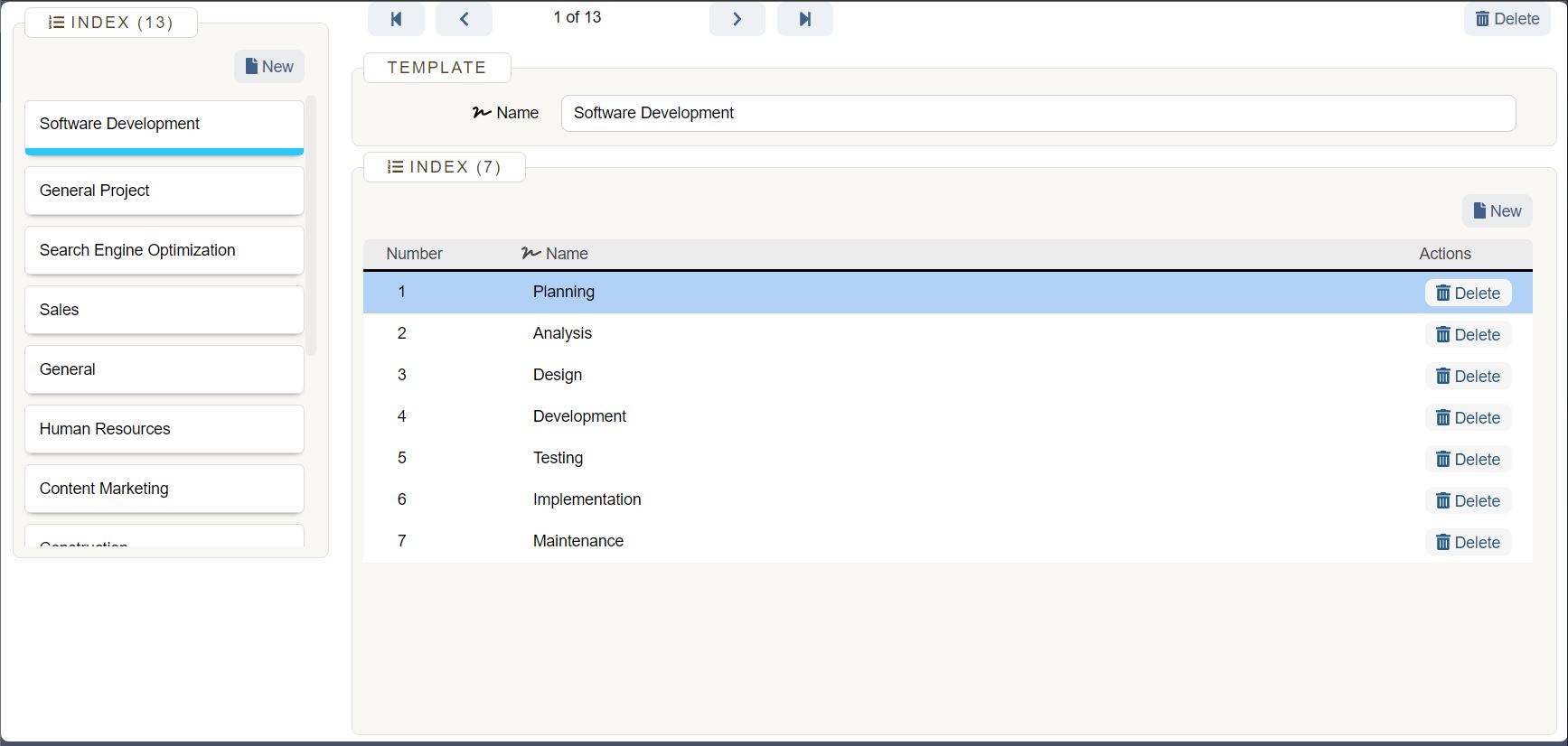

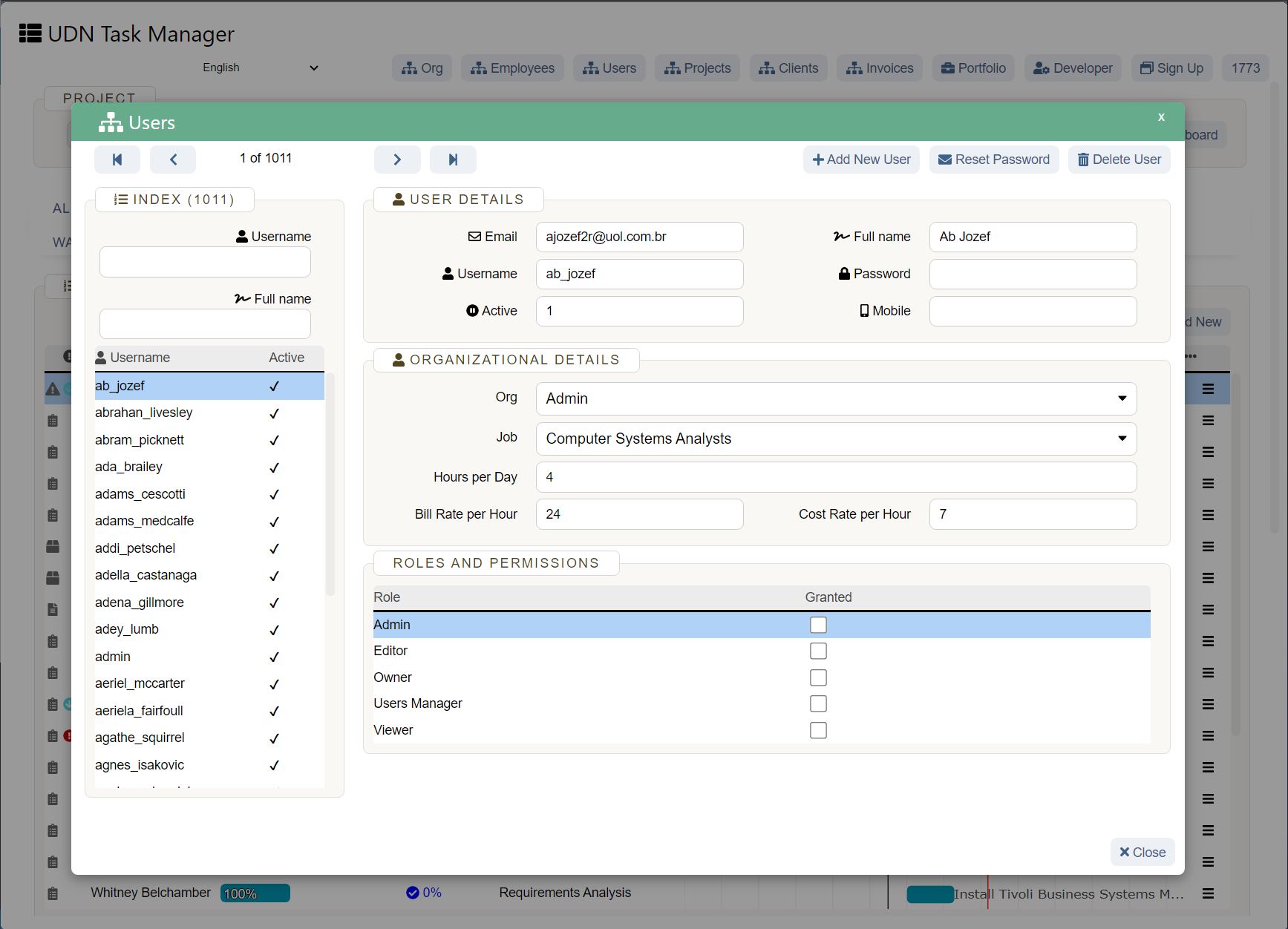

UDN Task Manager allows you to easily manage your complex project by breaking down events into tasks and subtasks. It allows for better collaboration by making it easier to delegate tasks. UDN Task Manager also helps in providing greater visibility and understanding of project variables such as timeline constraints, resource availability/utility and potential risk areas as identified by PERT. Furthermore, any changes in any task are shared in real-time with the whole team. The automated process reduces the chances of errors and mismanagement.

Also Read:

5 Common Project Management Challenges and Solutions to Tackle Them like a Pro