What Is Value Stream Mapping? (VSM)

Even though organization processes are set up to improve productivity and results, value stream mapping is the key to streamlining everything once you’re in the thick of it. Value stream mapping is used to uncover the people, processes, and effort it takes to reach an outcome. Understanding where your processes can improve means finding better solutions for customers and ultimately improving their experiences.

A strong understanding of where your processes work (and where they don’t) is becoming even more important these days, especially if your company aims to:

Operations, procedures, and workflows need to be monitored consistently to perform consistently. However, many product managers still see their project management style as static when making teamwide improvements. That couldn’t be further from the truth. Just like your offerings, your big picture and day-to-day processes always have room for improvement, and a value stream map is the best way to help find those areas.

Additionally, while it is true that everyone follows a team's prescribed process, the reality is that most of the time, processes are modified or simplified by individuals or teams. Using the value stream mapping approach, everyone from software engineers and developers to project managers can refresh their knowledge of how workflows can or should go.

Now sure where to begin? In this detailed guide to value stream mapping, you’ll discover:

What is value stream mapping?

Value stream mapping (VSM) is a process used to identify and improve the flow of information and materials required to produce a finished product or service before it reaches the customer. Understanding the value stream is very important when it comes to identifying the steps a company needs to take to create a high- quality product.

As the name suggests, a value stream map is a visual tool used for communicating complex information in a more digestible way. A value stream map shows all the critical steps in a product creation or service process. It also helps to identify the time and volume taken during each stage.

Many companies use value mapping to quantify the information that's being used in the given process. A great VSM can help determine if the process or organization of a project is overly complex or counterproductive. It can also be used to create a plan that addresses the issues it identifies while helping planners visualize specific goals and objectives for improvement.

To create a value stream map, you may choose to use a value chain diagram. A value chain diagram shows the various activities related to a material product or service. These are the activities that are typically referred to as "value streams." So when a value stream map is created, the information may come from here.

The goal of mapping a value stream is to identify and reduce waste in that stream. Doing so can help improve the efficiency of the process. Think of it as a summarized version of your workflow from start to finish. It will be used to define, assess, and improve existing processes so that teams can create a better customer experience.

The history of value stream mapping

Despite being around for a while, value stream mapping is still considered a new tool that can improve business efficiency. The concept of value stream mapping dates back to the 1980s. The original idea became the basis for the material and information flow diagram.

The term value stream mapping itself became popular after the books " The Machine that Changed the World " and " Lean Thinking " were released in 1990. The technique and waste theory were then further developed by Toyota during the early days of the Lean-Agile project management movement.

Today, value stream mapping is popular among software engineers and many other industries that aim to provide better customer experiences while also managing complex production processes.

What kinds of waste can you use value stream mapping to curb?

There are seven common types of waste that value stream mapping solves for:

Defects are defined as waste created by unsellable or refunded goods and services. These can be costly both in terms of revenue and brand reputation. Spotting defects ahead of time through value stream mapping is a realistic preventative measure any company can do.

Too much of a good or service can cause a ripple effect, leading to production delays, quality problems, and wasted time.

This means goods are not being transported or handled on time. This term also refers to an overly complex process or procedure that can be easily manipulated. One example of this is unsafe production.

You may also hear waiting to be referred to as a non-value-adding operation. This means any action or activity considered necessary to sustain a business, even though it does not contribute to its customer requirements.

Underutilized talent refers to team members who have extra time in their schedule for tasks that aren't being used. This can also mean assigning team members with special skills or knowledge to work that doesn’t make use of their abilities.

Unnecessarily moving physical goods and supplies from one place to another is an example of controllable transportation waste.

Overproduction refers to an accumulation of inventory that has become too heavy or created a burden in some way. This can result in increased lead times, difficulty identifying problems, or significant storage costs.

Similar to transportation, motion covers wasted resources that go from Point A to Point B, only in this case, it refers to people and not objects.

Additional processing refers to overworking a certain area, whether that’s extra steps or using too high-quality output for unnecessary aspects of the product or service that don’t have a proportionate effect on the end customer experience.

A successful operation involves identifying and correcting waste. When these areas of waste are identified, teams can solve these issues and create more productive processes.

Types of value stream maps

Mapping techniques are also used to analyze and design flows within lean environments.

Although value-stream mapping is commonly associated with manufacturing, it is used in various industries such as healthcare, logistics, and software development. Really any team that uses advanced product management strategies can take advantage of all that VSM has to offer.

There are two main types of value stream maps: current state and future state. The current state and future state value stream maps are used to determine the process's current state and its future state, just as the names imply.

The current state value stream map is typically created before the future state map so planners can understand where their processes currently are. This map is typically created by observing the flow of information and material in the system then communicating it.

Each value stream map has three key sections: information flow, product flow, and time ladder.

This section visualizes who is involved in communication, where communication happens, and how communication will flow between stakeholders.

You’ll typically see titles such as release manager, product manager, or team lead at the top. Depending on who you’re collaborating with, you’ll also want to include key stakeholder categories such as a client group or brand partner.

These are typically circled or underlined and connected via lines or arrows. If using lines, there should be a word or two (approvals, requests, etc.) on who does what when it comes to communication. If using arrows, this will dictate who is the go-between for clients and the rest of the stakeholders as they’ll point out how information cycles.

Towards the bottom of the section of the value stream map are the tools you’ll use to communicate. These can include project management software or even a spreadsheet program. Even if you use an entire suite of communication applications, it’s best to focus on your most centralized communication and task management hub here.

These tool names will also be circled or put in boxes. Lines or arrows will connect these boxes to the next stage: product flow.

The product flow box will outline the number of processes you have, which teams work on them, plus the cycle (C/T) and setup (S/T) times for each. It will also connect the beginning and endpoints to relevant stakeholders in the communication section.

Process should move left to right on the map. They should also contain all the related details within their respective box. This section remains independent from the final section, which is known as the time ladder.

The time ladder is a visual representation of the production lead and processing time of this particular section. Days are represented by high horizontal lines and hours are represented by low horizontal lines. While not to scale, the horizontal lines are all connected via vertical lines, making the time ladder one long continuous line. You may also choose to include a callout box with a summary of the total C/T and S/T represented in the time ladder to the side of this section.

What are the benefits of value stream mapping?

Mapping a value stream helps identify areas of waste while also uncovering knowledge gaps, improving communication, and making collaboration easier. But it’s the end result that is most important: a renewed focus on the customer.

For example, when a project gets handed off from one team to another, it's important that all relevant knowledge and resources go to the other team. If something goes wrong, you don’t want the new team to waste time reinventing the wheel. With value stream mapping, you can identify waste and minimize it before issues come up.

There may be errors in the tools you use or the time it takes to complete a certain project phase. When information is represented visually, it makes it easier for C-level executives to assess the real versus imagined process labor involved. It’s also a great way to see who is or is not in the loop.

A value stream map helps identify gaps in communication across teams and departments. It also defines the flow of communication. This is helpful when working with third parties and vendors since information sharing is especially important in a successful project plan.

Along those same lines, a VSM can help managers, clients, stakeholders, and team members better understand everyone’s role in the project. It also defines each major process and the expectations around effort. Having one neat summary of all this information in a visual format makes it easier to collaborate effectively since everyone is on the same page.

Your primary focus should always be on the customer. But with so many teams and moving parts, it can be hard to keep that focus long term, especially during busy seasons. This is why value stream mapping is so important. It cuts through the noise to streamline the steps between ideation and actually helping people.

How to conduct a value stream map

The start and endpoints of a mapping exercise can vary depending on your goals. A value stream map can cover operations for an entire department. But it can also drill down on specifics. For example, each individual product or service can have its own value stream map. With all of that in mind, here are the essential steps you can use to conduct a value stream map.

Mapping a process involves gathering information to identify its various stages and procedures. This is the initial step in developing a process activity map.

List out the components of the product or service that bring value to your customer. Rank them in order of importance. This provides a foundation for business decisions while also giving your team a strong starting point for your value stream map.

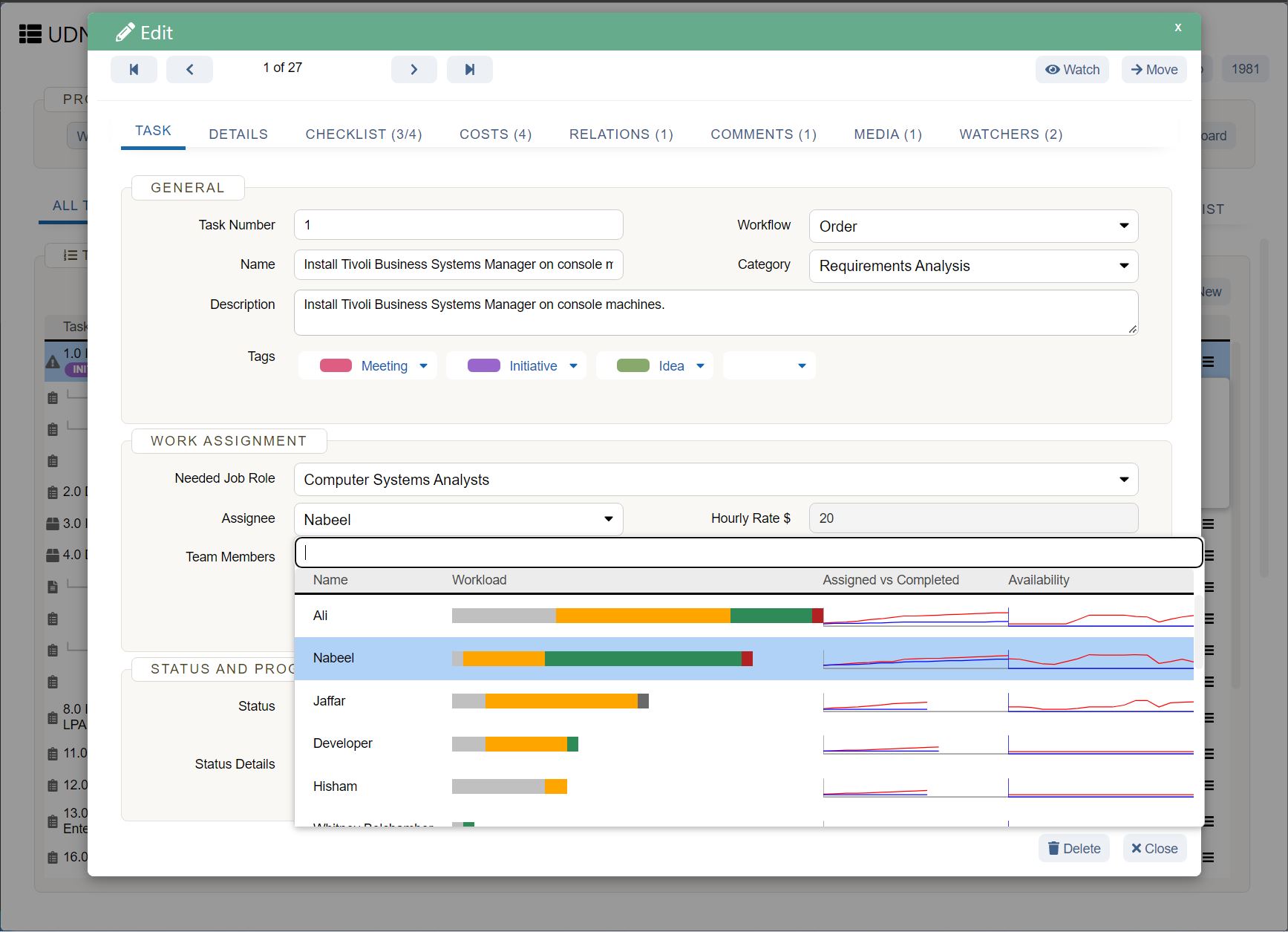

Determine who will lead the project and see it from start to finish. This person will act as a point for related communications. They’ll also draft and revise the value map itself. You’ll also want to build a team that will be responsible for each individual process. A VSM can also communicate where their processes fit into the bigger picture.

The point of creating a value stream map is to solve a problem. But you can’t solve a problem if you don’t understand what it is. Again, keep your focus on the customer. Ask your team what the issue looks like from your audience’s perspective, then go from there.

Consider what you’re trying to solve, what the issue may be, and what a realistic solution looks like. From there, you can focus your VSM on a big picture process or hone in on one specific process within the greater project landscape.

Before you start working on a map, make sure that you know what problems you cannot solve and what solutions you need to implement before taking further action.

Get started mapping out your process steps and timeline. This will help you identify areas of improvement and will also help you improve your lead time.

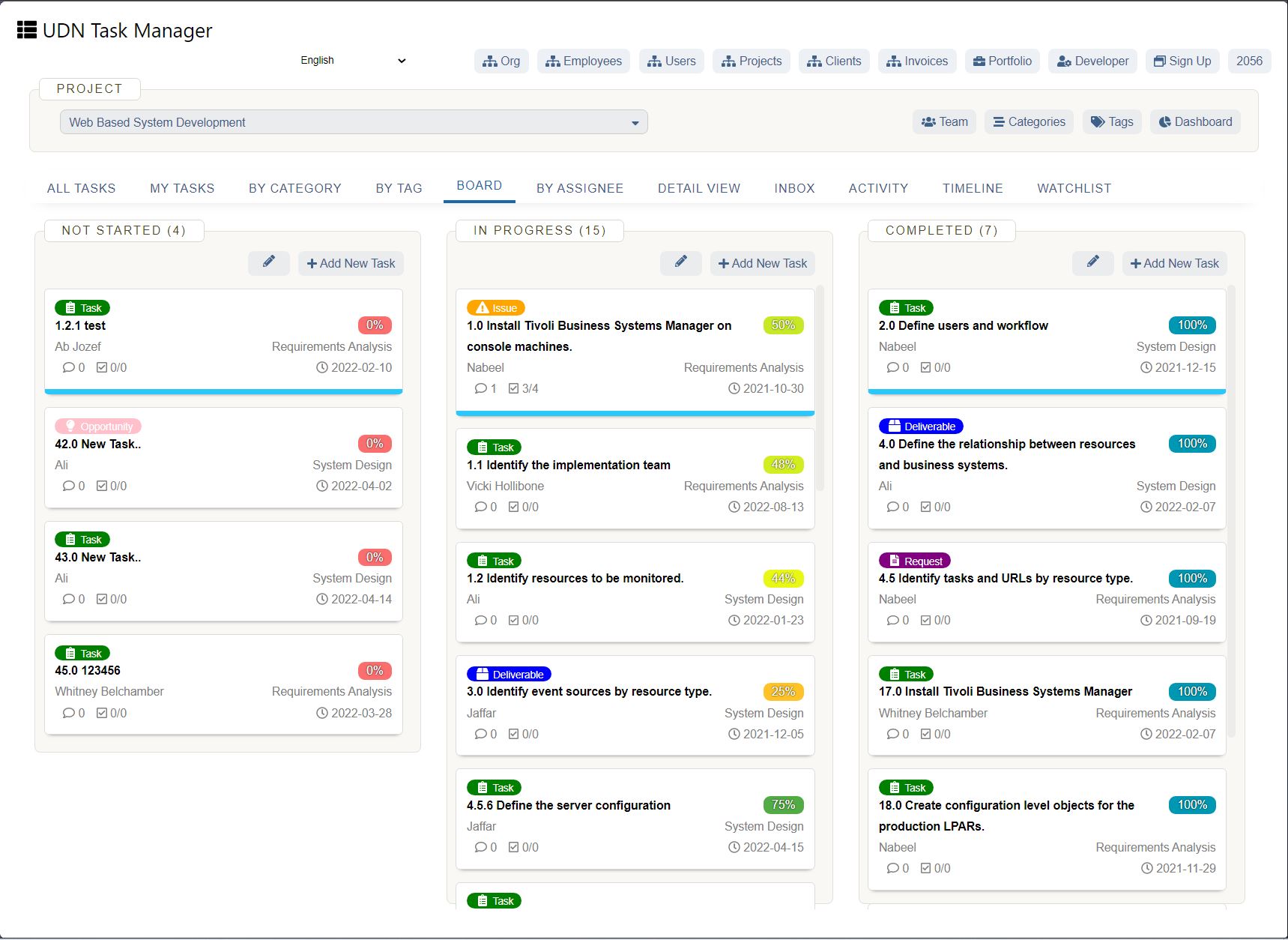

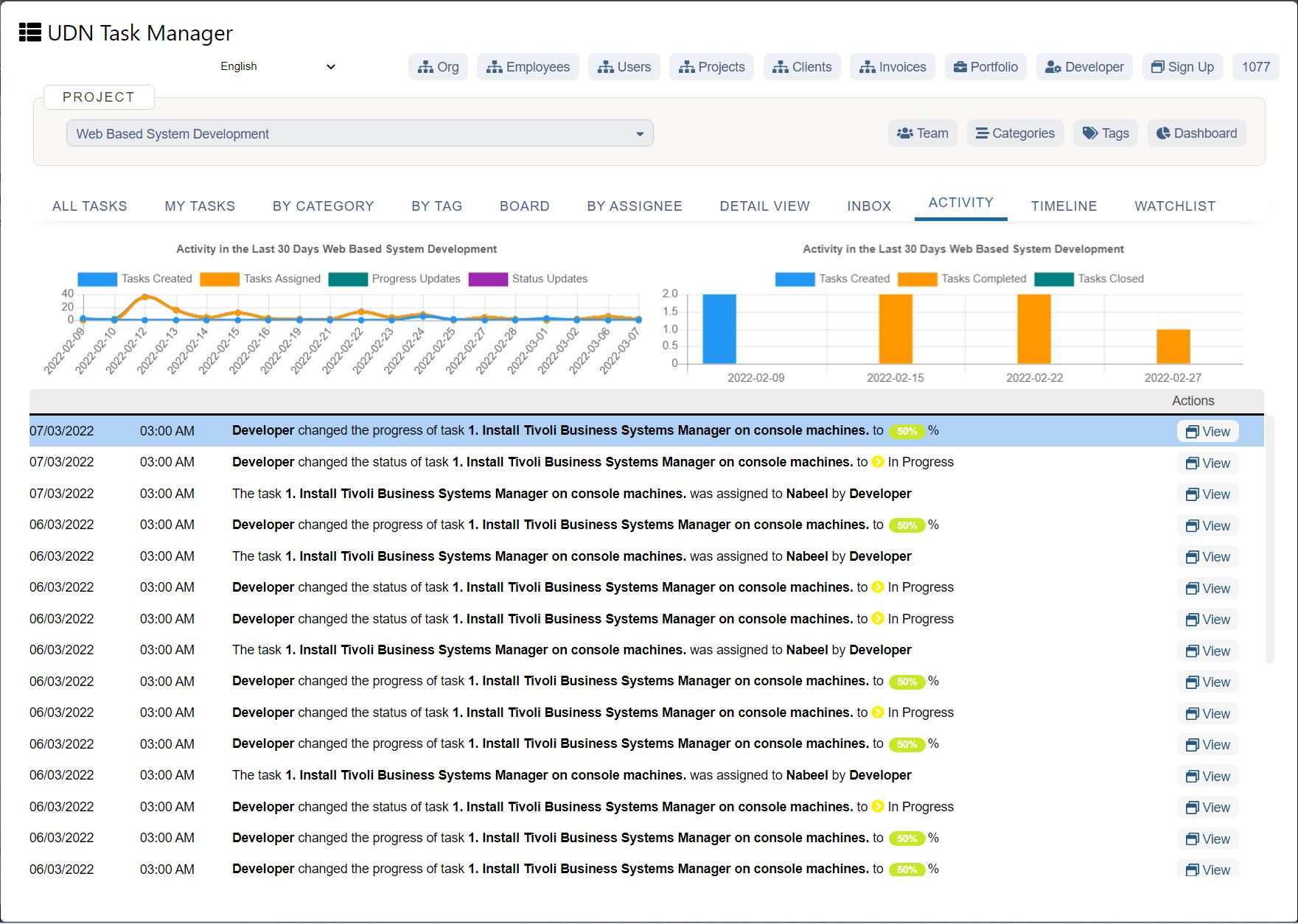

Use a document tool or a value stream mapping generator to visualize your data points. Keep descriptions short but clear. Try color-coding to further divide the three major sections. And be sure to call out details that are unique to your project in the side margins where needed.

Remember that the value stream mapping should also be collaborative. As a team, add additional details together. Doing this eliminates the need for deep-dive explorations and discoveries separate from the VSM creation process. This will also help minimize the number of repeat tutorials needed and allow team members to come up with additional questions on the spot.

Share your VSM with your team. Ask them where they see potential stumbling blocks. Also, be sure to get stakeholders involved at this stage if they aren’t already. They may have preferences that clash with your productivity strategy. If that’s the case, sharing the value stream mapping draft with them can visually communicate the differences in a way that may shift their perspective.

Once everyone has signed on to the draft, it’s time to polish up any leftover notes and finalize. Share it with the group, along with a short bulleted list of any changes made between the last draft and the final one.

How do you conduct a value stream map analysis?

To properly read and find takeaways from a value stream map, you’ll need to learn how to analyze it.

There are many ways to identify and address the value stream challenges that you may face. One of the most common methods is to start with a basic overview of the current state of your organization. This method will typically identify areas of weakness and potential opportunities for process improvement . A good baseline can even help you measure efficiency across various levels of detail.

Others will start with a clear idea of their goal and how they will reach it. For example, if they know that they have to have a certain threshold, they will begin with that and work their way up until they reach their goal.

And still, others will begin with the end in mind: the customer. Once a customer-oriented goal has been created, it's easier to assess your current state VMS and create the future state VSM that will serve as steps to reach the best possible outcome.

Start by using your current state VSM to identify:

After, develop a goal or target state VSM that shows what the prioritized value stream should look like. Make a note of the differences between the two and find areas in need of improvement. Improvement can vary widely depending on the organization and its goals. Some of these can be achieved by implementing changes in procedures, adopting automation, or hiring additional support.

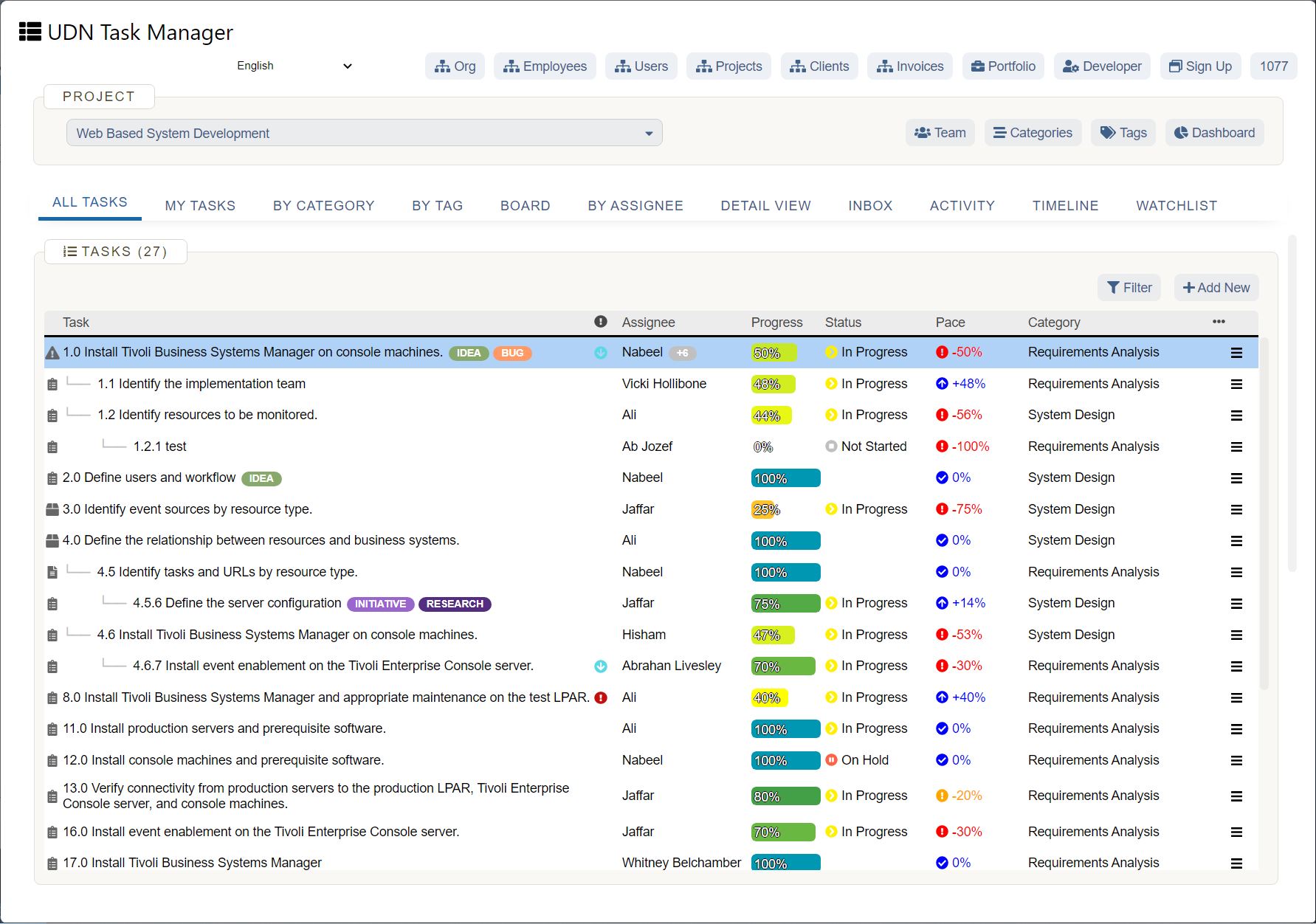

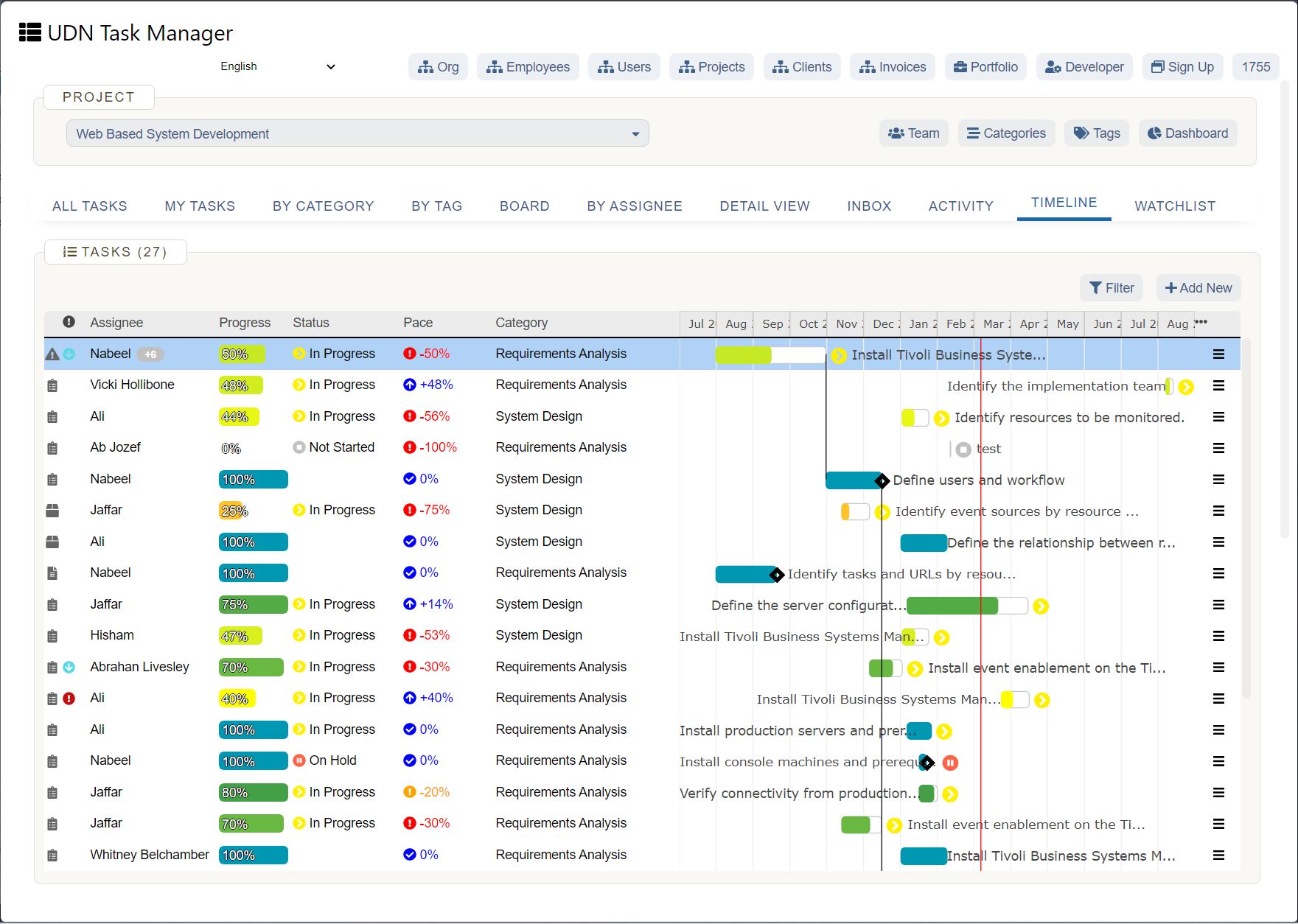

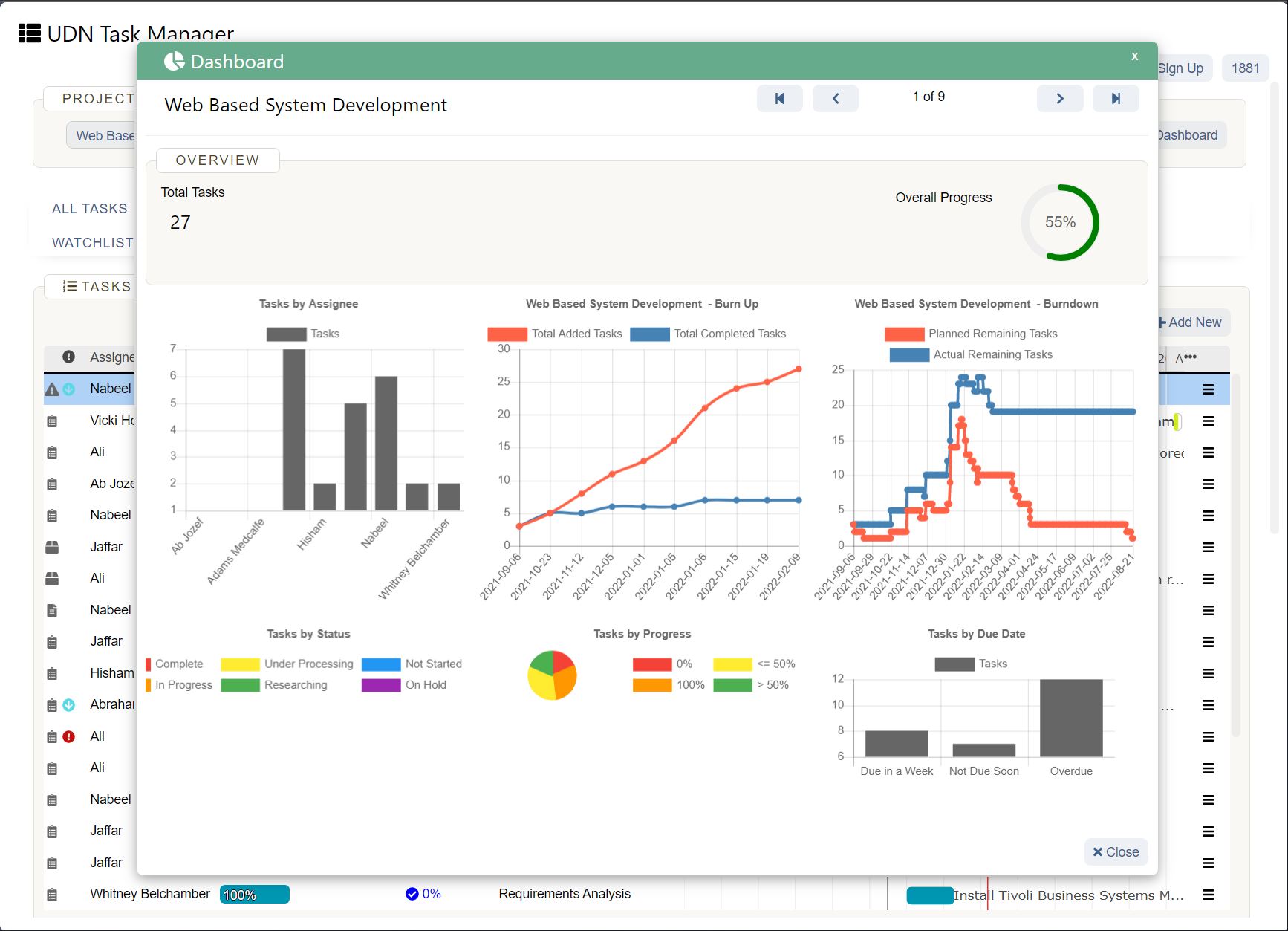

Then, turn the next steps into an actionable product roadmap within your project management software. Assign these tasks to the appropriate parties with due dates and an overall project timeline to ensure accountability.

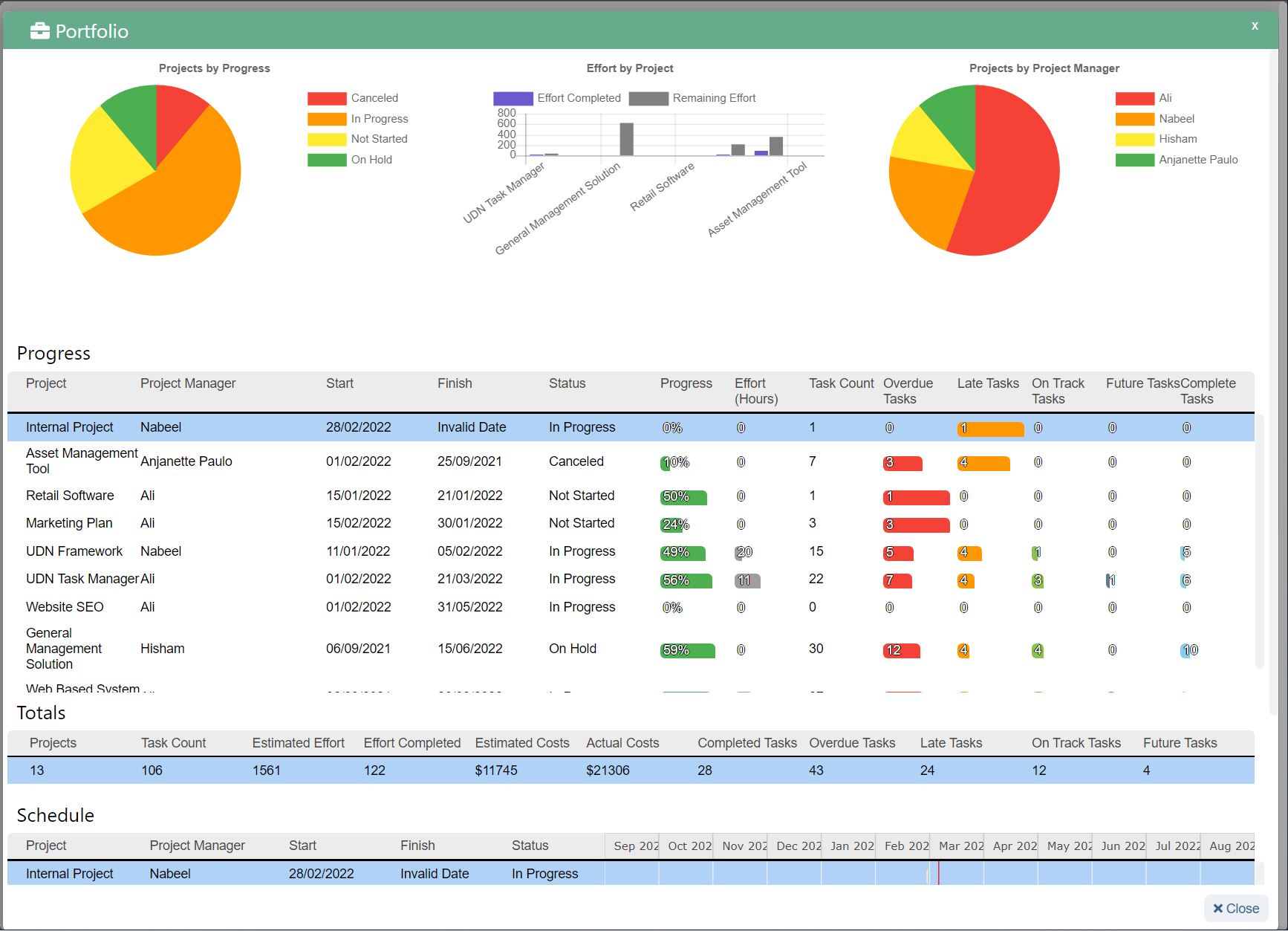

Keep in mind that the goal is to continuously improve processes . This means value stream mapping should become less of a one-off project and more of a habit for you and your team. In fact, establishing a consistent process and monitoring program is an integral part of any successful VSM strategy. This could mean scheduling this project to recur monthly or quarterly, depending on your needs and bandwidth.

Conclusion

The goal of every company is to develop a culture that enables teams to provide the best possible products, services, and experiences to customers. Once you have full visibility into your processes, your entire organization can streamline limited project resource management and operations.

Interested in organizing your next value stream mapping project? Use UDN Task Manager as your one source of truth for task management, data capturing, and team collaboration to greatly improve all your business processes. Start your free trial today .