What is value stream mapping (VSM)?

Summary

Value stream mapping (VSM) is a way to analyze your current state of work and develop a more efficient future state. This process helps you visualize how you work so you can uncover areas that need improvement. In this piece, we’ll explain the value of VSM and how to create your own value stream map.

When you organize a cluttered closet, the first step is to remove everything from the space. Laying everything out gives you a better sense of what you have, making it easier to reorganize.

Work improvements are similar in that it’s hard to notice inefficiencies without spreading everything out in front of you. Doing this with your workflow can reveal problems you didn’t notice before—that’s where value stream mapping comes in handy.

What is value stream mapping?

Value stream mapping is a flowchart method used to illustrate and analyze a production process. VSM is a key component in lean project management —an Agile methodology that increases customer value by eliminating waste from each project phase.

Value stream mapping (VSM) involves four basic steps:

Map current process

Find and eliminate waste

Map improved, future process

Implement future process

You may notice room for improvement in areas of your value stream map such as:

Process flow

Lead and processing times

Equipment reliability

Raw materials/inventory

When you find waste in your production flow, like overproduction, mismanagement, or project defects, you can then manage these bottlenecks so your process flows smoothly.

When should you use value stream mapping?

Value stream mapping can lead to significant improvements in your business model. But you shouldn’t invest time and resources on VSM if it doesn’t fit your needs. Here are situations when you should use value mapping:

To improve an end-to-end work process

To identify piled up inventories in a process

To find opportunities for process optimization

To learn the inherent complexities of a process

To understand the IT systems used in a process

To assess the effectiveness of customer service channels

To visually display the health of your processes

To strategically review your processes

As you can see, creating a value stream map provides insight into many aspects of a work process. However, a value map may not be helpful if you’re trying to solve a problem that has no relation to information, product, or time flow.

How to create a value stream map

Value stream mapping has four basic steps, but you’ll feel more prepared if you expand the process into nine steps. The first five steps in the VSM process focus on project planning. Having a project plan increases your insights and may lead to better process improvements. Then, you can get started on the four basic steps of VSM with all of the context you need.

1. Identify the problem

Value stream mapping is an important part of regular workflow maintenance, but you can also use it to solve a team or customer problem you’re already aware of. For example, you may notice that your customer demand is higher than the amount of inventory stock you have available. When you notice a problem but don’t know the cause, you can share the issue with your team and use VSM to find solutions.

Tip: In this initial stage, brainstorm and ask questions to identify both internal and external inefficiencies. Put yourself in the position of your customer and your team members so you can find pain points.

2. Choose your team

You’ll need a determined and focused team to help you map the value stream, closely analyze it, and implement your improved production process. A cross-functional team of members from the sales, operations, customer service, and design departments will give you the skills and perspectives you need to optimize process times and meet customer needs. Depending on the problem you're trying to solve, you may not need representatives from all of these teams. Choose wisely to make your VSM team as efficient as possible.

Tip: Employ both executives and those in supporting roles on your VSM team to increase visibility into internal issues. Invite suppliers or other stakeholders to join your group if you want an outsider’s point of view.

3. Define the project scope

Your value stream mapping exercise is a project of its own, which means you’ll need to define your scope. If you don’t define your project scope , you won’t know how much of your work processes to map out. Lack of defined scope also makes it harder to identify and eliminate waste later on.

Tip: Only use VSM for one product at a time. Decide whether to map the product life cycle in its entirety or focus on specific process steps. If you’re producing a software product, you can map the process from the initial feature request to customer delivery. Leave out conditional steps that may occur once the customer receives the product.

4. Map your value stream

Now that you’ve scoped your VSM, you can begin your map. Use value stream symbols (explained below) to show how information flows between your work activities. If you’re mapping out your entire production process, your map will create a circle. The final stage of the production process should cycle back to the initial process step.

Tip: If you aren’t sure where to start your value stream map, begin with the team member in charge of approving requests between a customer and a supplier. You can also visualize your map in three parts. Dedicate the top part of your map to information flow, the middle part to product flow, and the bottom part to time flow.

5. Add project data

Once you have an illustration of your value stream, add relevant metrics to get the most accurate insights from this exercise. While the map alone can help you visualize certain things, like your company’s manufacturing process or software development, you’ll need to pair the image with data boxes to compare things like time, quantity, and quality between all of the process steps.

Data points you can add to your map include:

Amount of inventory held for each step

Cycle time per unit

Transfer time

Number of team members needed to perform each step

Number of products scrapped

Number of products in each processing batch

Takt time (rate needed to produce products in order to meet customer demand)

Tip: The data you include in your map will vary depending on your industry, the process you’re mapping, and what problems you hope to solve. Most data will fall within these three categories:

Office or support data

Manufacturing or shop data

Supplier or outside processing data

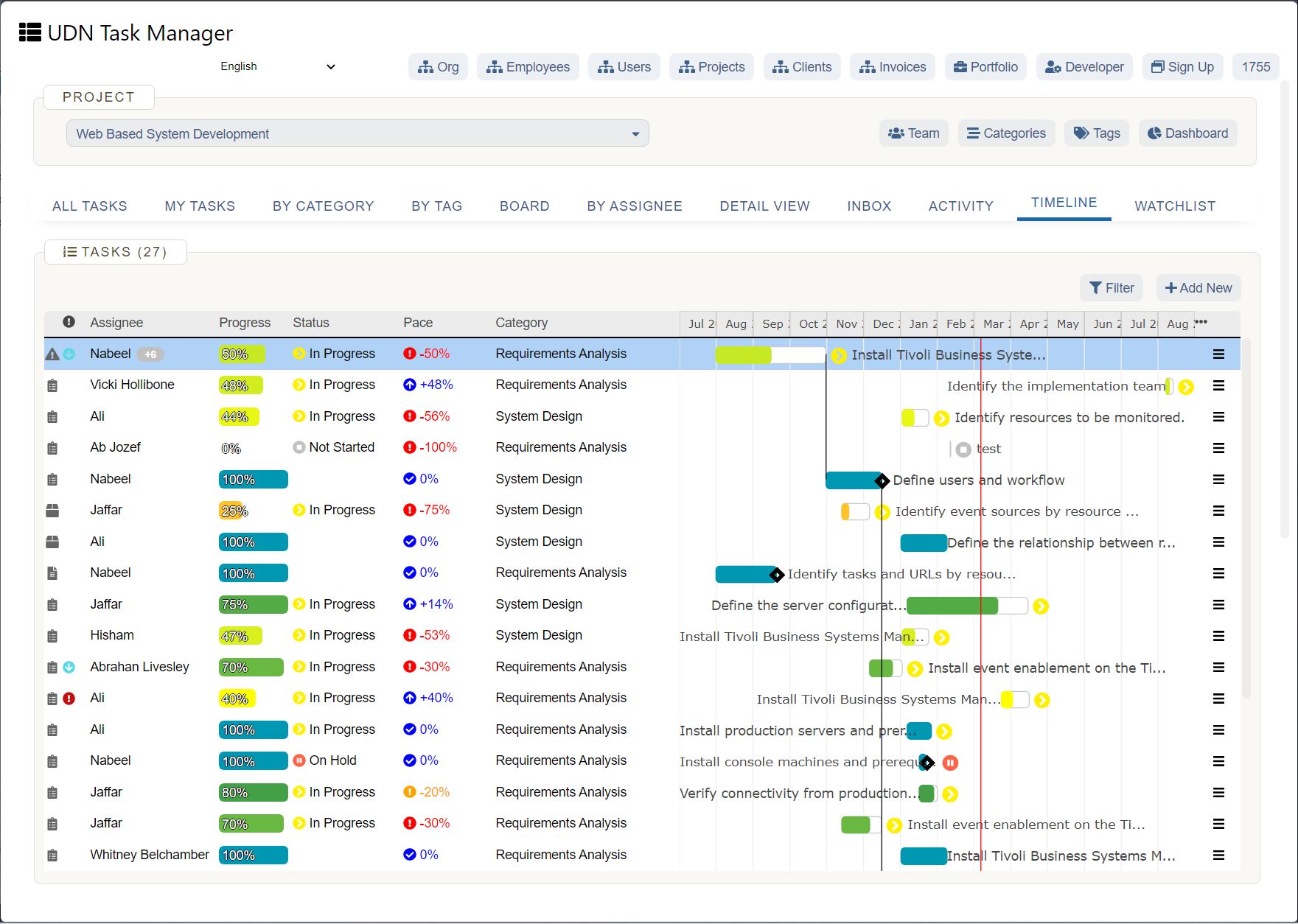

6. Create a timeline

A clear timeline is essential to any production process, and delays can throw off your entire workflow. You’ll dedicate the bottom third of your value stream map to time flow using a time ladder, which has two rungs for lead time and cycle time. This ladder will give you a better sense of whether your lead time and cycle time are up to speed.

Lead time is the total time it takes for your team to complete a task, starting when a task first enters your workflow. Lead time includes all of the operational processes leading up to the actual production stage.

Cycle time is the part of your total lead time when you're actually completing a task. This is sometimes known as value-added time.

Calculate lead time by taking stock of the inventory available before each process step and dividing it by the customer demand for the product. For example, imagine youif you have four of your products available before heading into the shipping process step and the customer demand for the product is two products per day, then your lead time is two days.

Tip: Lead time is closely tied to inventory management and customer satisfaction. If your lead time is too long, you’ll have trouble predicting when to replenish your inventory. Your value stream map can help you optimize lead times before you find yourself behind on product delivery.

7. Analyze your current map

As you build your current flow state map, you’ll likely notice areas that need optimizing. To complete your value stream map, fill it in with project data to make the areas of waste more visible.

However even if the areas of waste seem obvious, you should still set focused time aside for map analysis. Areas of waste in lean management include:

Overproduction (unnecessary features)

Inventory (mismanaged backlog)

Motion (task switching)

Defects (technical debt)

Over-processing (expensive tools)

Waiting

Transport

Fragmented teams

Tip: The best way to analyze your map is by performing kaizen bursts on any areas of waste you’ve identified. The word kaizen comes from two Japanese words: kai, meaning improvement, and zen, meaning good. Combined, the two words create the idea of continuous improvement. You’ll use kaizen bursts to generate value-adding ideas for the future state value stream map.

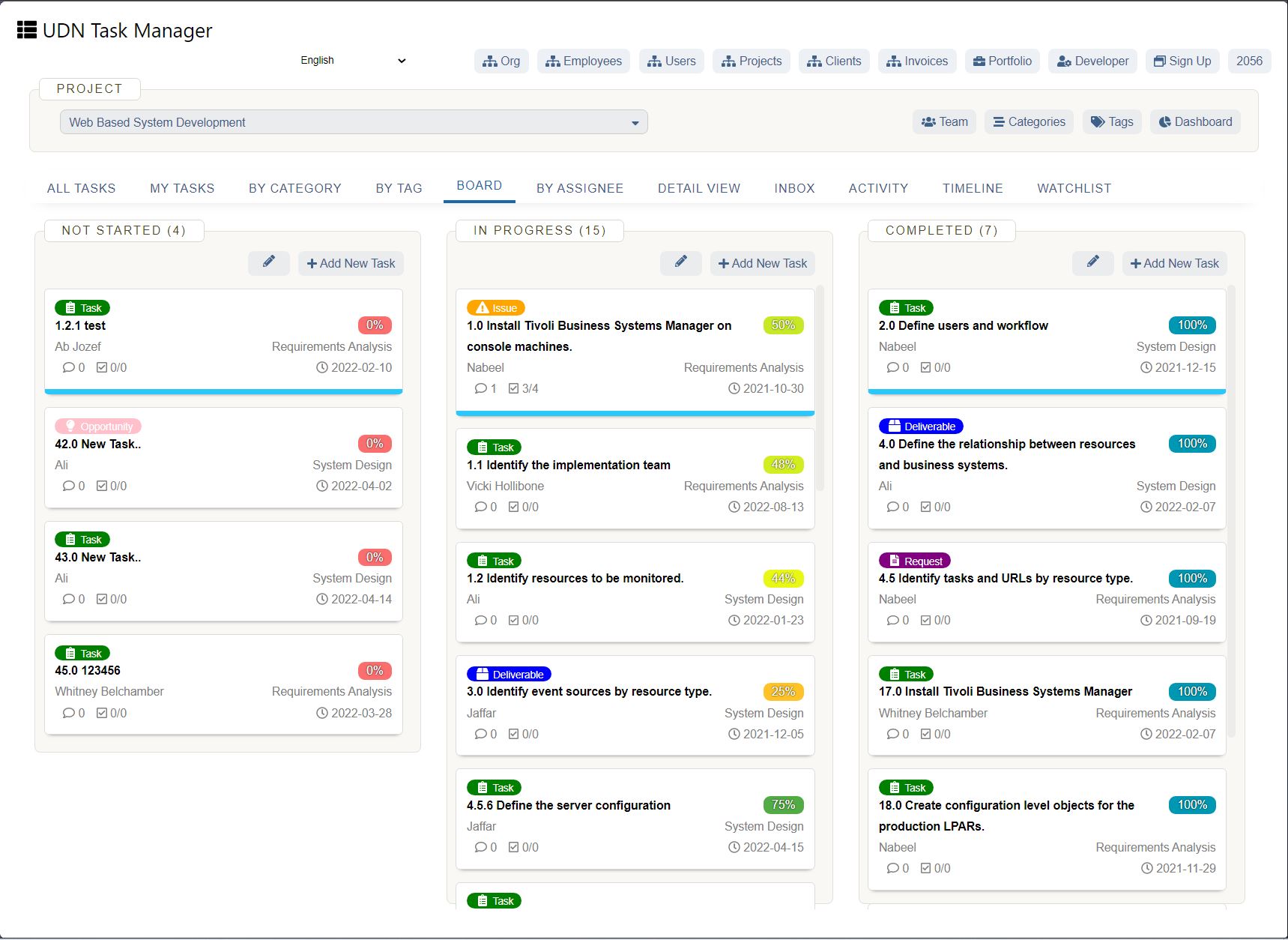

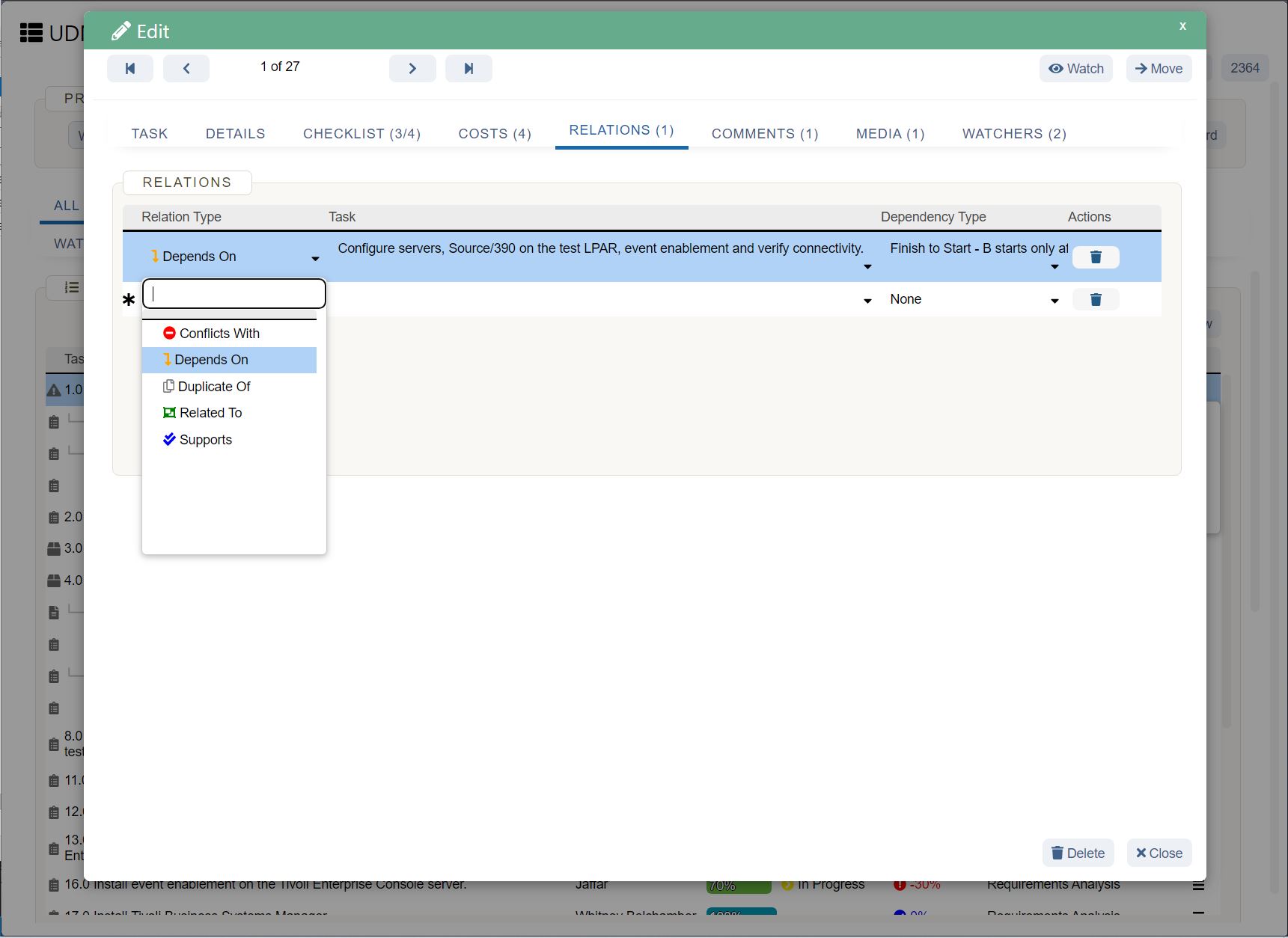

8. Design your new map

You’re now ready to draw your future state value stream map. This map will look similar to your current map, but include elements of kaizen for areas needing improvement. You can use Kanban software to implement a pull—or pull resources only when demand calls for them—and improve your flow of information.

The specific symbols you add to your future state map will vary depending on your process. See the VSM symbol map below for visual representations of the following:.

Supermarket: Represents a Kanban stock point where customers can get the inventory they need as soon as the supplier replenishes it.

Production Kanban: Indicates the need for product to supply parts to a downstream process.

Material withdrawal Kanban: Instructs an operator to move parts from a supermarket to a process.

Signal Kanban: Used when inventory levels in a supermarket are low, and signals production of a specified number of parts.

Kanban post: Indicates location for collecting Kanban signals, typically located near a supermarket.

Material pull: Represents removal of stored inventory from supermarkets.

Sequenced pull: Eliminates the need for supermarket storage of inventory between processes by instructing a specified team to produce a custom order.

Tip: Use the value stream symbol map below to see what each symbol looks like and place them in your future state map accordingly. While the goal of your future state map is to simplify material flow, don’t worry if your future state map looks more crowded than your current state map because of the symbols you’ve added.

9. Implement your new map

The last step in the VSM process is to implement solutions from your future state map into your work process. This is where you’ll see the analysis of your map pay off.

Like organizing a closet, it feels chaotic to sort through clutter, but the project’s purpose becomes clear once you feel the ease of using your newly functional space. While identifying waste and finding leaner solutions is challenging, the final product is a more efficient workflow and happier customers.

Value stream symbol map

The following symbols represent information flows, work activities, and areas that need improvement in your processes. When you use VSM software, you’ll have a bank of these symbols readily available for you to use.

Value stream mapping example

Below you’ll see a VSM example of a current state map. This map outlines the process of a product or service passing from the supplier, through the internal production chain, and to the customer.

The value stream map begins top of center with the team member in charge of production control. This person approves requests or orders from customers and sends these requests to the supplier. Notice that this value stream map example runs in a circular motion because customer demand feeds both the supply and production chain.

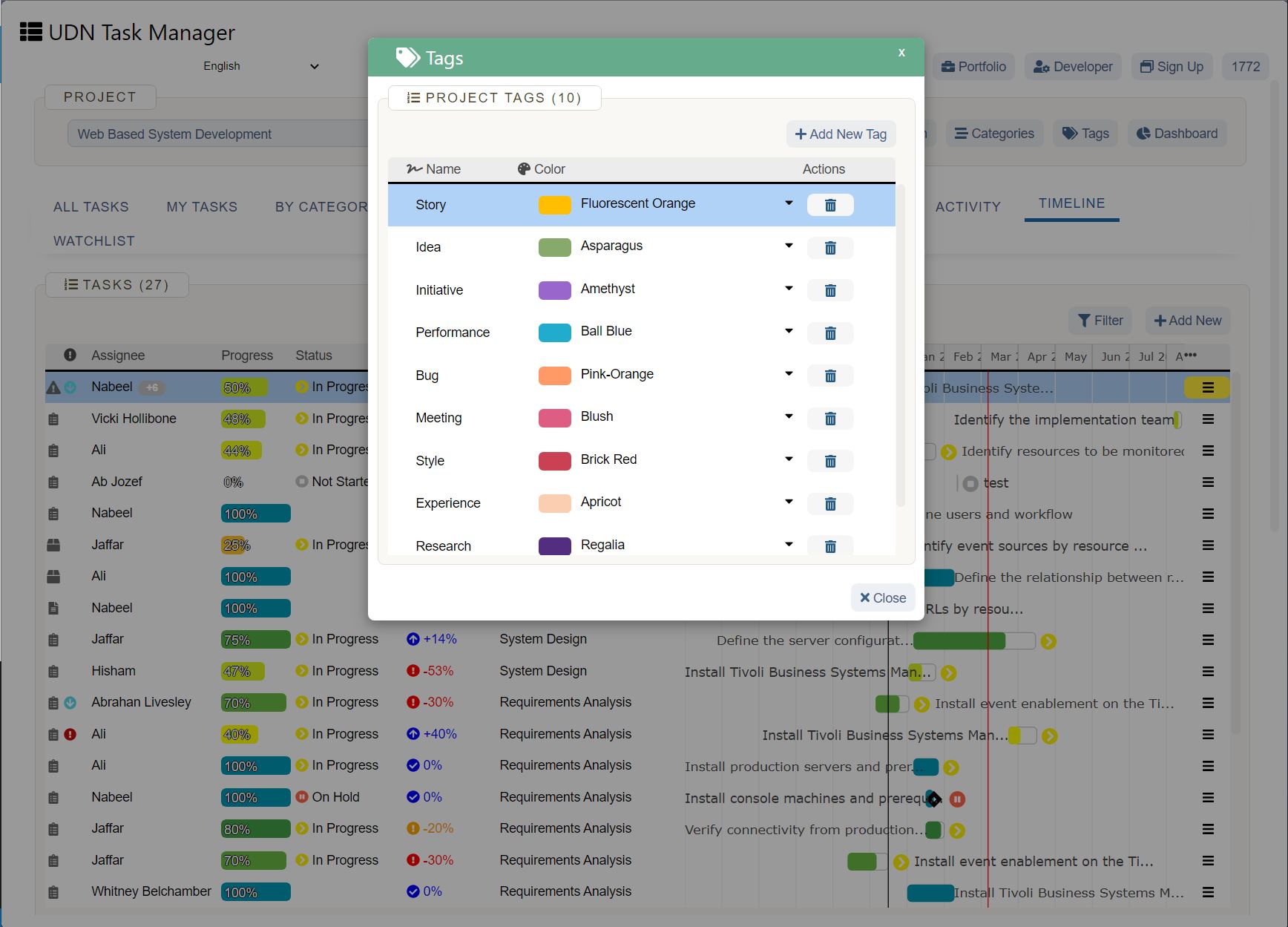

Create an efficient workflow with value stream mapping

If you’re striving for continuous improvement, perform regular upkeep to your processes, just as you would with your home. While VSM can feel tedious, the outcome is a more efficient workflow that has less waste and lower lead times.

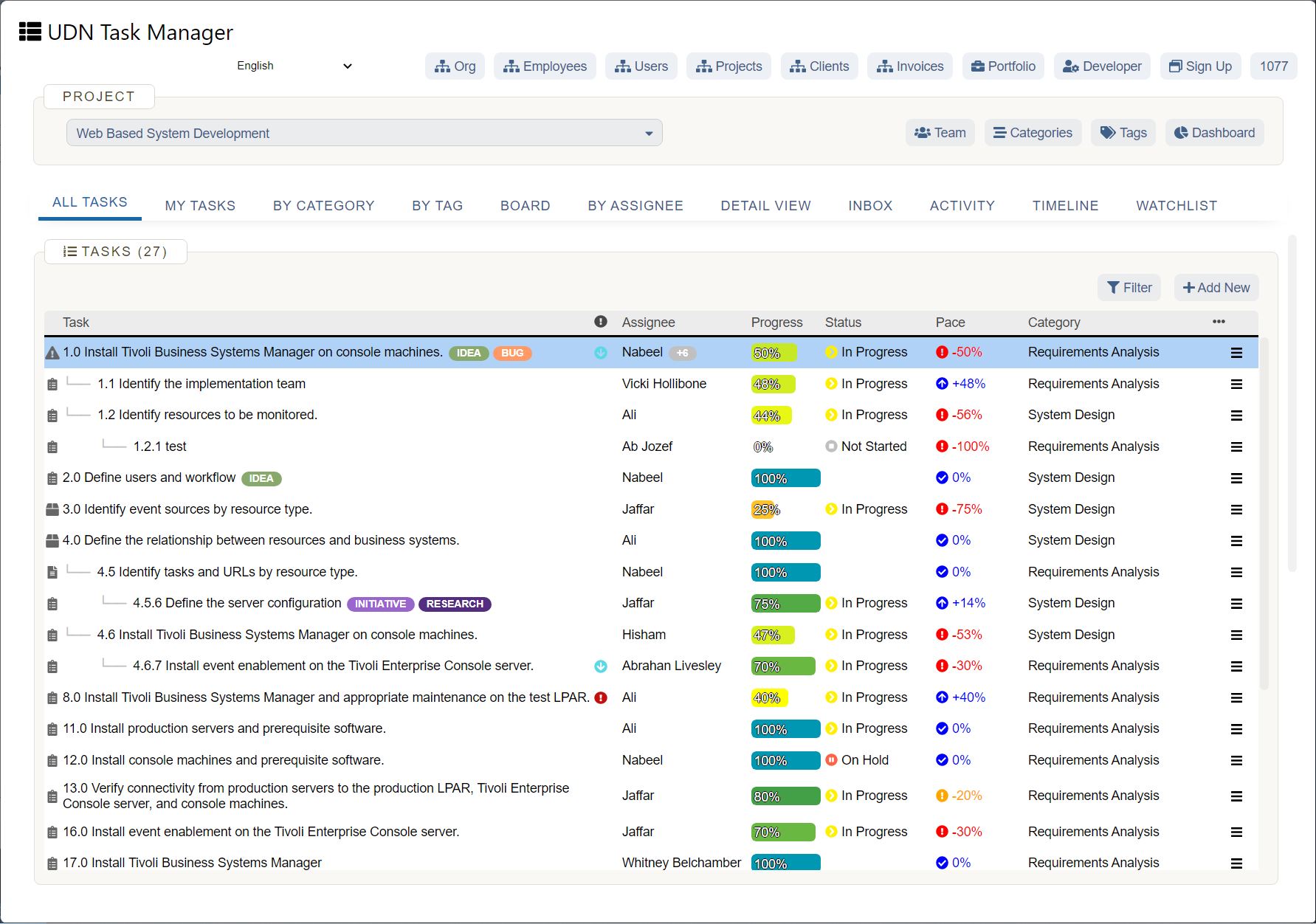

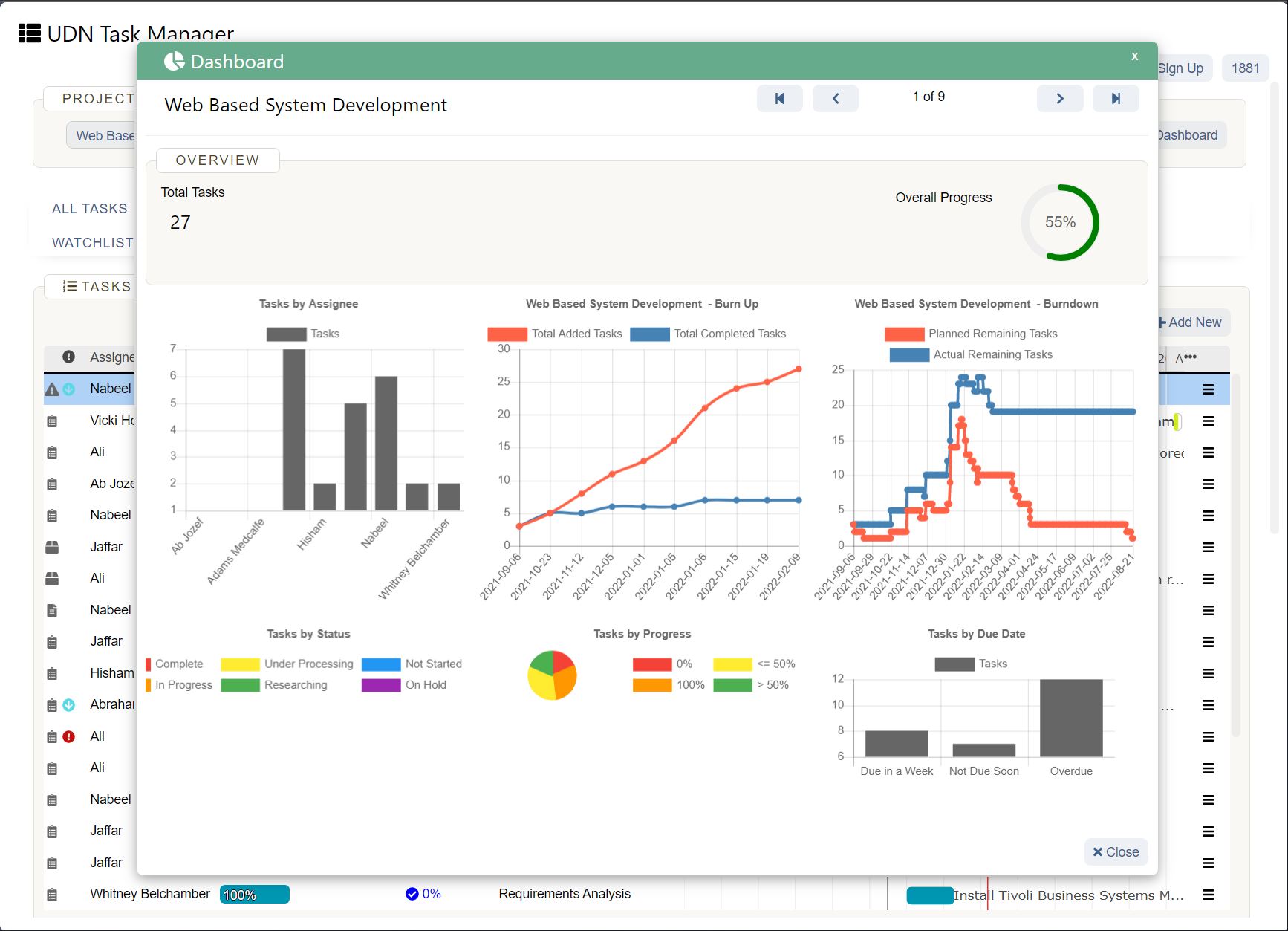

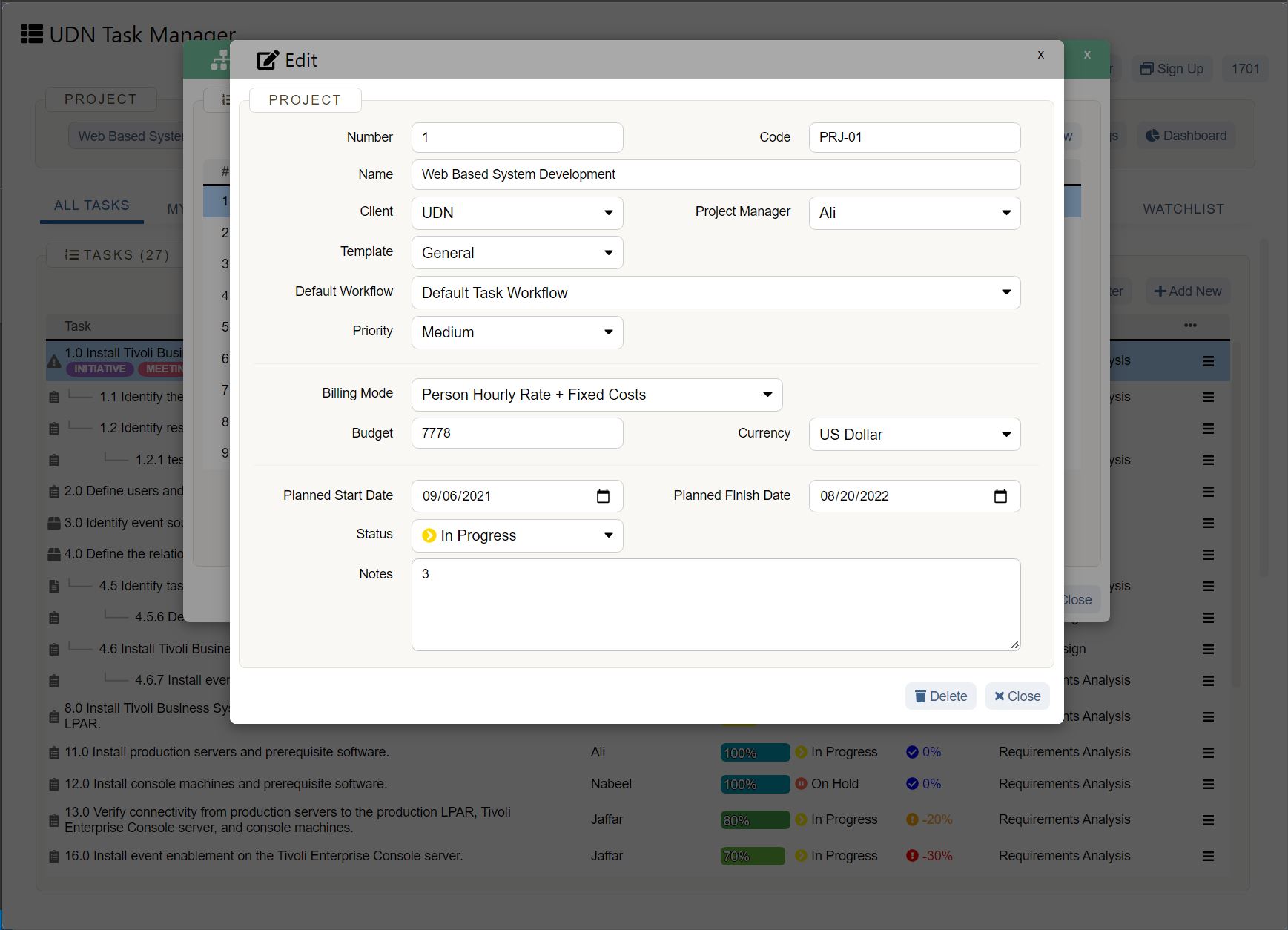

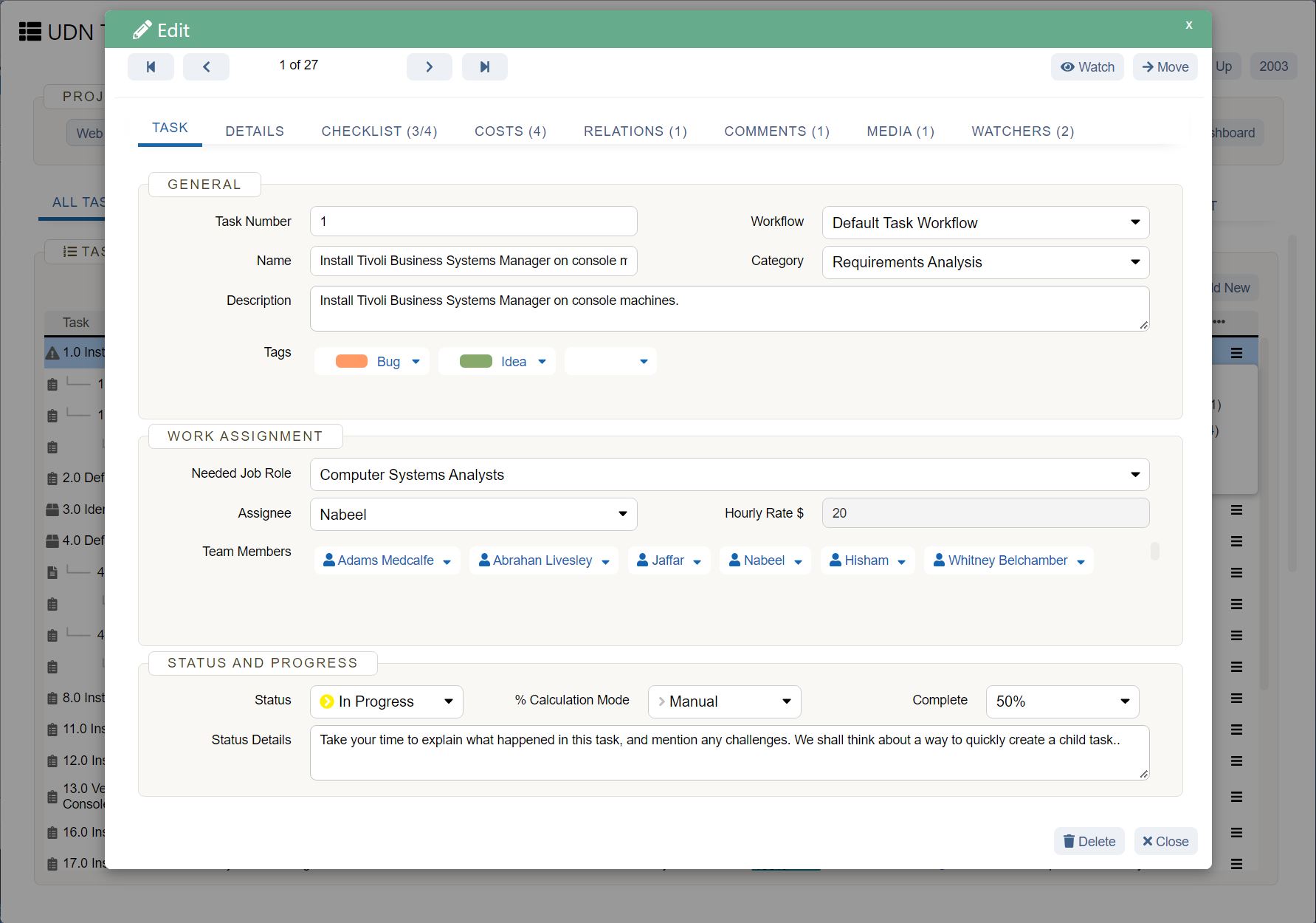

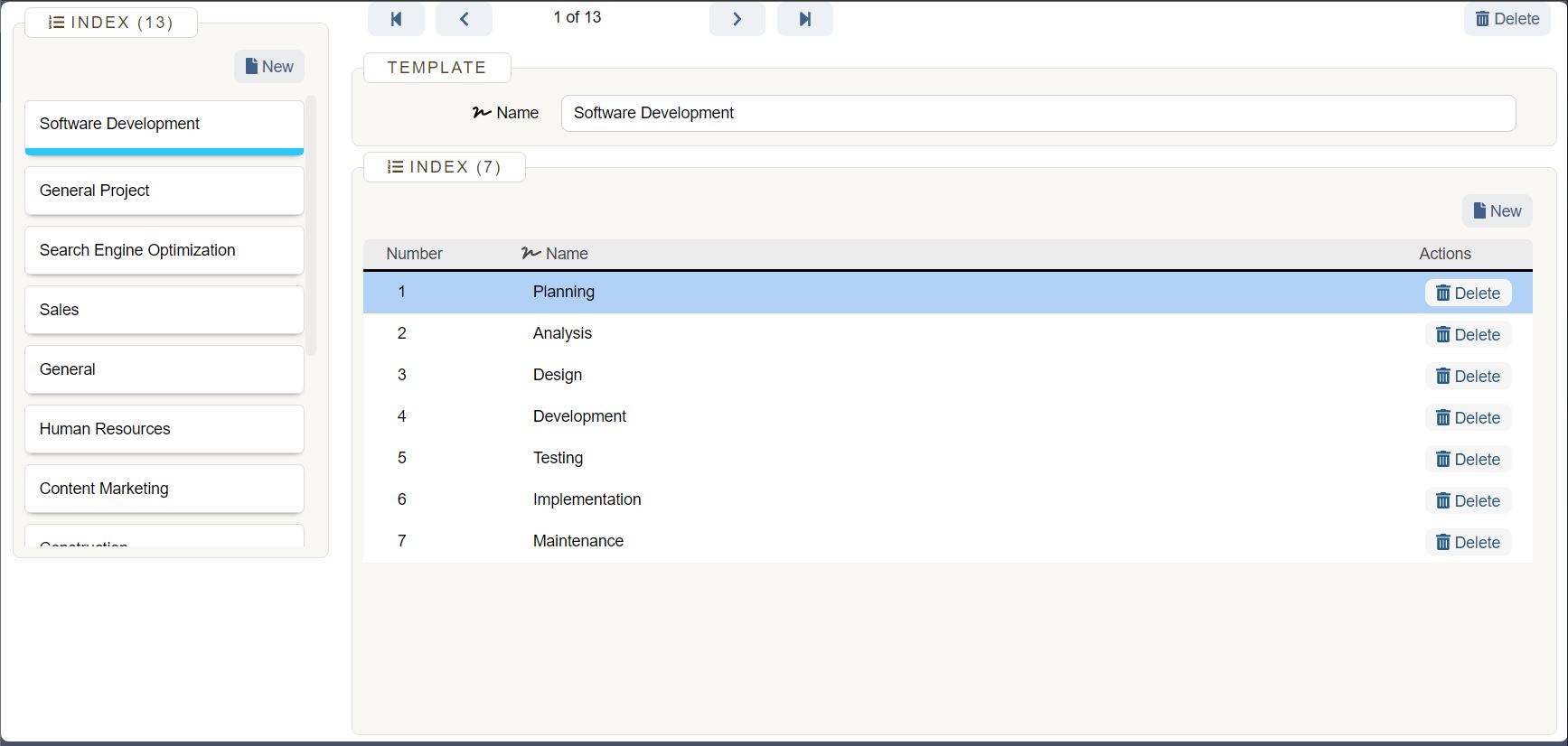

Mapping your current and future value stream is easier when using proper software. When you integrate your value stream map with UDN Task Manager , you can quickly implement your solutions and get back to satisfying your customers.