Six Sigma: Everything you need to know about this process improvement methodology

Summary

Six Sigma is a process improvement method that helps organizations improve their business processes. The end goal of Six Sigma is to reduce the amount of variations in a process as much as possible in order to prevent defects within your product. While this methodology is often used to optimize manufacturing processes, it can also be applied to other industries—including tech companies who produce digital products rather than physical ones.

Imagine your development team is in the process of putting the final touches together for a big product launch. When the product gets to the testing stage, the team catches several unanticipated bugs in the code. How can your team prevent this from happening in the future?

One way to do this is to implement an old manufacturing tool: The Six Sigma methodology.

What is Six Sigma?

Six Sigma is a process improvement methodology that helps organizations improve their business processes. Six Sigma’s main objective is to help you establish uniform processes to decrease the amount of variations in your end product. Ultimately, this minimizes the amount of product defects.

The main philosophy of Six Sigma is that all processes can be defined, measured, analyzed, improved, and controlled (commonly referred to as the DMAIC method). According to Six Sigma, all processes require inputs and outputs. Inputs are the actions that your team performs, and the outputs are the effects of those actions. The main idea is that if you can control as many inputs (or actions) as possible, you also control the outputs.

Where does Six Sigma come from?

Developer Bill Smith created the Six Sigma methodology while he was an engineer at Motorola in 1986. The term “Six Sigma” originates from statistical modeling in the manufacturing process. Basically, you can identify the maturity of a process by its “sigma” rating, which indicates the percentage of products that are defect free. By definition, a Six Sigma process is one in which 99.99966% of opportunities produced are statistically expected to be free of defects.

Six Sigma is commonly used in manufacturing and production because the process helps prevent the amount of defects produced. However, this methodology can also be used in the service industry and with software engineering teams.

Lean Six Sigma

In general, the goal of a lean methodology is to drive out waste or anything that doesn’t add value to a product or process. The lean Six Sigma methodology values defect prevention over defect detection. This means that the goal of lean Six Sigma is not to identify where the defect is, but to prevent defects from happening in the first place.

The 5 key principles of Six Sigma

The Six Sigma methodology has 5 key principles you can use when analyzing your processes.

1. Focus on the customer

In Six Sigma, the goal is to ensure you can provide your customers with as much value as possible. This means your team should spend a lot of time identifying who your customers are, their needs, and what drives their behavior to purchase products. This principle works well for SaaS companies since they often focus on recurring revenue streams. Identifying your customer’s wants and needs can help your team better understand how to retain customers and keep them coming back to your product.

This requires your team to understand the quality of product your customers would find acceptable, so you can meet, or even exceed their expectations. Once you understand that level of quality, you can use it as a benchmark for production.

2. Use data to find where variation occurs

Outline all of the steps of your current production process. Once you’ve done this, analyze and gather data on the current process to see if there are certain areas that can be optimized or areas that are causing a bottleneck in your workflow. For example, consider how you share information with your team. Is everyone on your team getting the same information, or are they referencing outdated documents? Establishing a centralized location for all pertinent project information can help minimize the amount of time spent searching for the right documents.

Sometimes it can be challenging to decide what metrics you need to analyze. An easy way to figure this out is by working backwards. Identify a goal you want to achieve and work back from there. For example, if your goal is to shorten production time, analyze how long each step in the production process takes.

3. Continuously improve your process

While you’re looking at your production process, consider any steps that don’t add value for your team or your end customers. Use tools such as value stream mapping to identify where you can streamline processes and decrease the amount of bottlenecks.

The idea of making small improvements to your processes over time is known as , or continuous improvement. The philosophy behind continuous improvement is that if you’re making small changes over a long period of time, it can lead to major positive changes in the long run.

4. Get everyone involved

Six Sigma is a methodology that allows everyone on the team to contribute. However, this does require everyone on the team to have some training on the Six Sigma process to reduce the risk of creating more blockers instead of getting rid of them.

Six Sigma works especially well when cross-functional teams are involved, because it provides a holistic view of how a process can affect all parts of your business. When you include representatives from all teams involved in a process, you give everyone insight into the improvements you’re making and how those changes might impact their teams.

5. Ensure a flexible and responsive ecosystem

Six Sigma is all about creating positive change for your customers. This means you should consistently look for ways to improve your processes, and your entire team should stay flexible so they can pivot without much disturbance.

This also means that processes need to be easily interchangeable. An easy way to do this is to break out processes into steps. If there’s an issue with just one step, then only that step needs to be fixed, as opposed to the entire process.

The 2 main Six Sigma methodologies

There are two common processes within Six Sigma and they’re each used in different situations. The DMAIC method is the standard method and is used when existing processes need to be optimized. The other method is the DMADV method and it’s used when processes are not yet established and need to be created.

The DMAIC method

DMAIC is an acronym, meaning each letter represents a step in the process. DMAIC stands for:

Define the system. Identify your ideal customer profile, including your customers’ wants and needs. During this stage you also want to identify the goals of your entire project as a whole.

Measure key aspects of current processes. Using the goals you established in the “Define” stage, benchmark your current processes and use that data to inform how you want to optimize your project.

Improve or optimize your process. Based on the analysis from the previous step, create a new future state process. This means you should create a sample of the improved process and test it in a separate environment to see how it performs.

Control the future state process . If the results in the “improve” stage are up to your team’s standards, implement this new process into your current workflow. When doing this, it’s important to try and control as many variables as possible. This is often done using statistical process control or continuous monitoring.

A product team notices that the customer churn rate (the rate at which customers stop doing business with you) is increasing. To prevent this from happening any further, they use the Six Sigma DMAIC methodology to identify the issue and develop a solution.

Define: The customer churn rate has increased from 3% to 7% in the last 6 months.

Measure: The team has a lot of information about how prospective customers convert into actual customers, but there’s not much information about what happens after someone becomes a customer. They decide to analyze and measure user behavior after they purchase the product.

Analyze: After looking at the behavior of users after they become customers, the team notices that newer customers are having a harder time getting used to the new product UI than existing customers.

Improve: The team decides to implement a “new customer onboarding” workflow that helps customers identify key parts of the product and how to use it. For larger customers, the team works with the customer success team to help set best practices and create trainings. This gives the customer success team all the information they need to train new customers effectively.

Control: The team monitors both the churn rate and how customers are behaving now that the changes have been implemented. After a few months, they notice the churn rate beginning to decrease again, so they choose to keep the new changes to the process.

The DMADV method

The DMADV method is sometimes referred to as Design for Six Sigma (DFSS). DMADV stands for:

Define your goals. When establishing goals for the new process you’re establishing, it’s important to consider both business goals and the goals of your ideal customer profile.

Measure and identify CTQs . CTQ stands for “critical to quality.” These are the characteristics that define your perfect product. During this step you will identify how your new process can help achieve these CTQs and add any potential risks that could impact quality.

Analyze to develop and design multiple options. When you’re designing a new production process, it’s important to have multiple options. Take a look at the different options you create and analyze the strengths and weaknesses of each one.

Design the chosen option. Based on the analysis in the previous step, take the next step and implement the option that best fits your needs.

Verify the design and set up pilot runs. Once you finish implementing your process, it’s time to hand it over to process owners and measure how the process works. Once the process is up and running, then your team can optimize it using the DMAIC method.

Six Sigma belt rankings

When you’re learning the Six Sigma methodology, you’ll see that there are different ranking levels. Similar to martial arts, each ranking is a different belt color.

White belt: If you’re brand new to the Six Sigma method, you’ll start out in this stage. Someone with a Six Sigma white belt doesn’t need to have any formal training or certification in Six Sigma, but they understand the basic framework and guidelines. This means they can participate in waste reduction and quality control projects.

Yellow belt: This level requires some formal training in Six Sigma, and you can receive an official yellow belt certification. An individual with a yellow belt can help contribute to strategy more than a white belt can. They assist higher-ups with problem solving and analysis.

Green belt: Once you receive your certification for a green belt, you can start strategizing and implementing smaller process improvement techniques on your own.

Black belt: Individuals who receive Six Sigma black belts are able to break down processes and handle more complex projects than any belt previously. They’re taught how to manage large-scale changes that can impact a business’ bottom line.

One of the most effective ways to climb the rankings in Six Sigma is to take certification courses. While there is no unified standard for certification, these courses are designed to teach the essentials of the Six Sigma process and how to apply them to your day-to-day work situations.

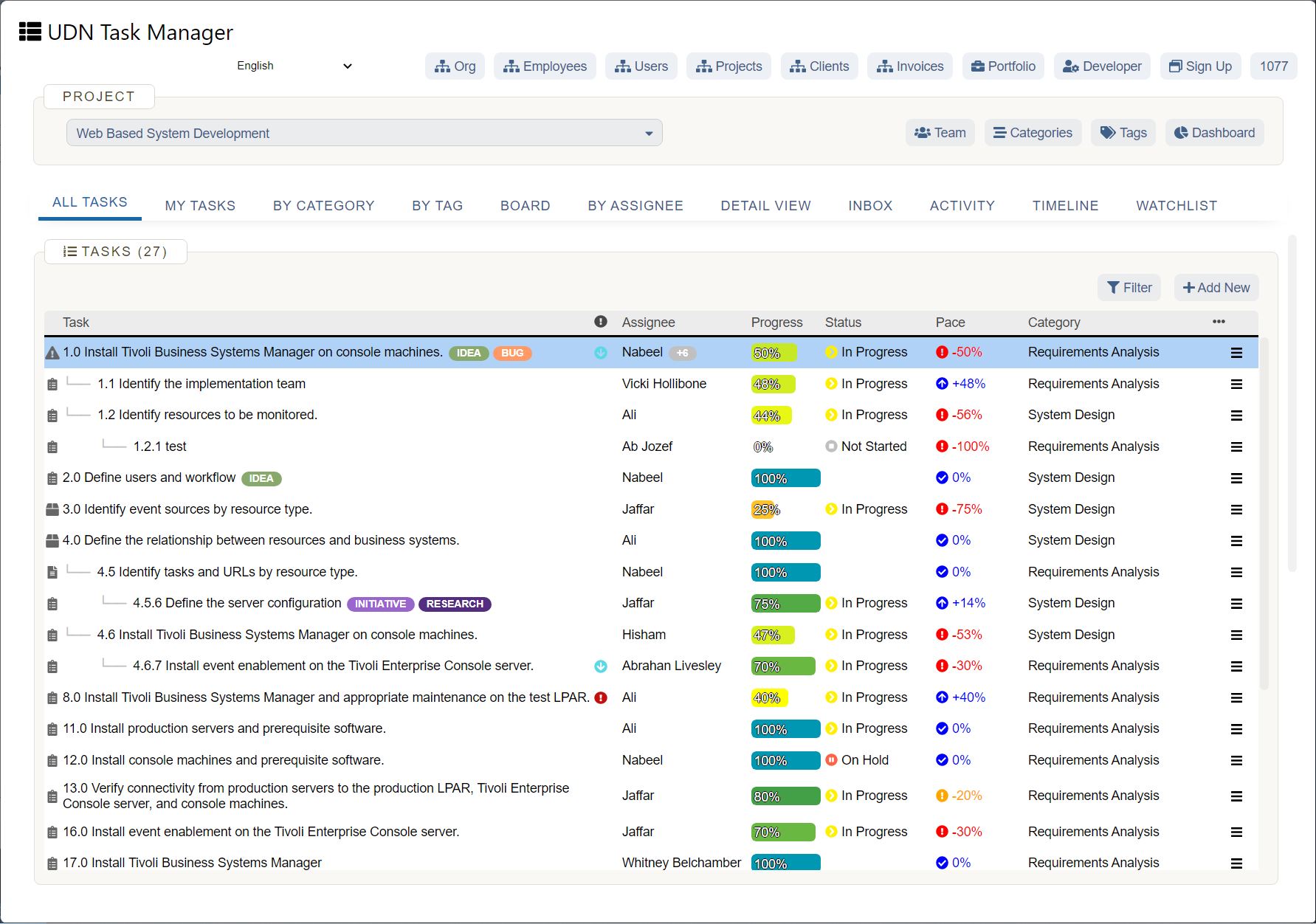

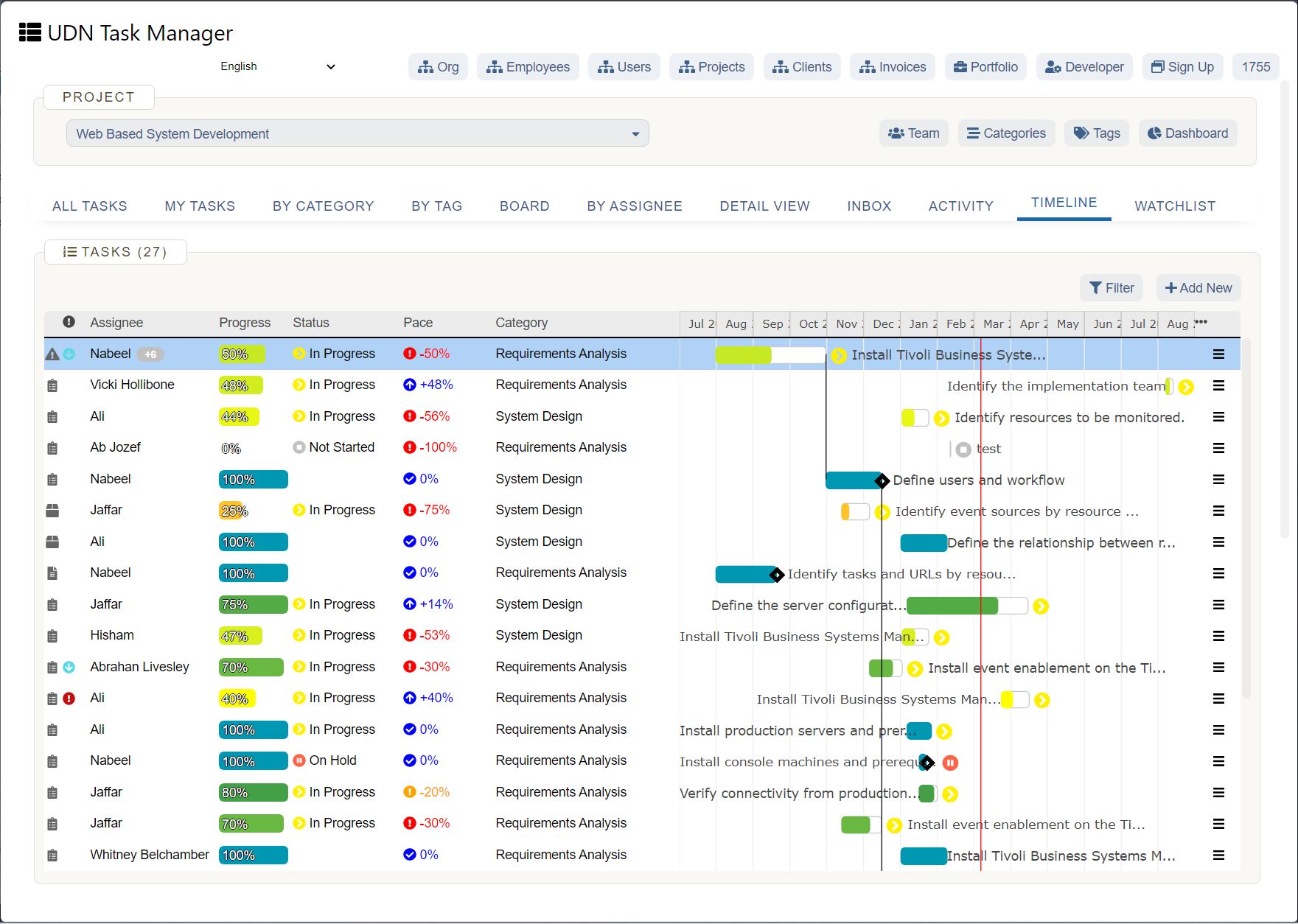

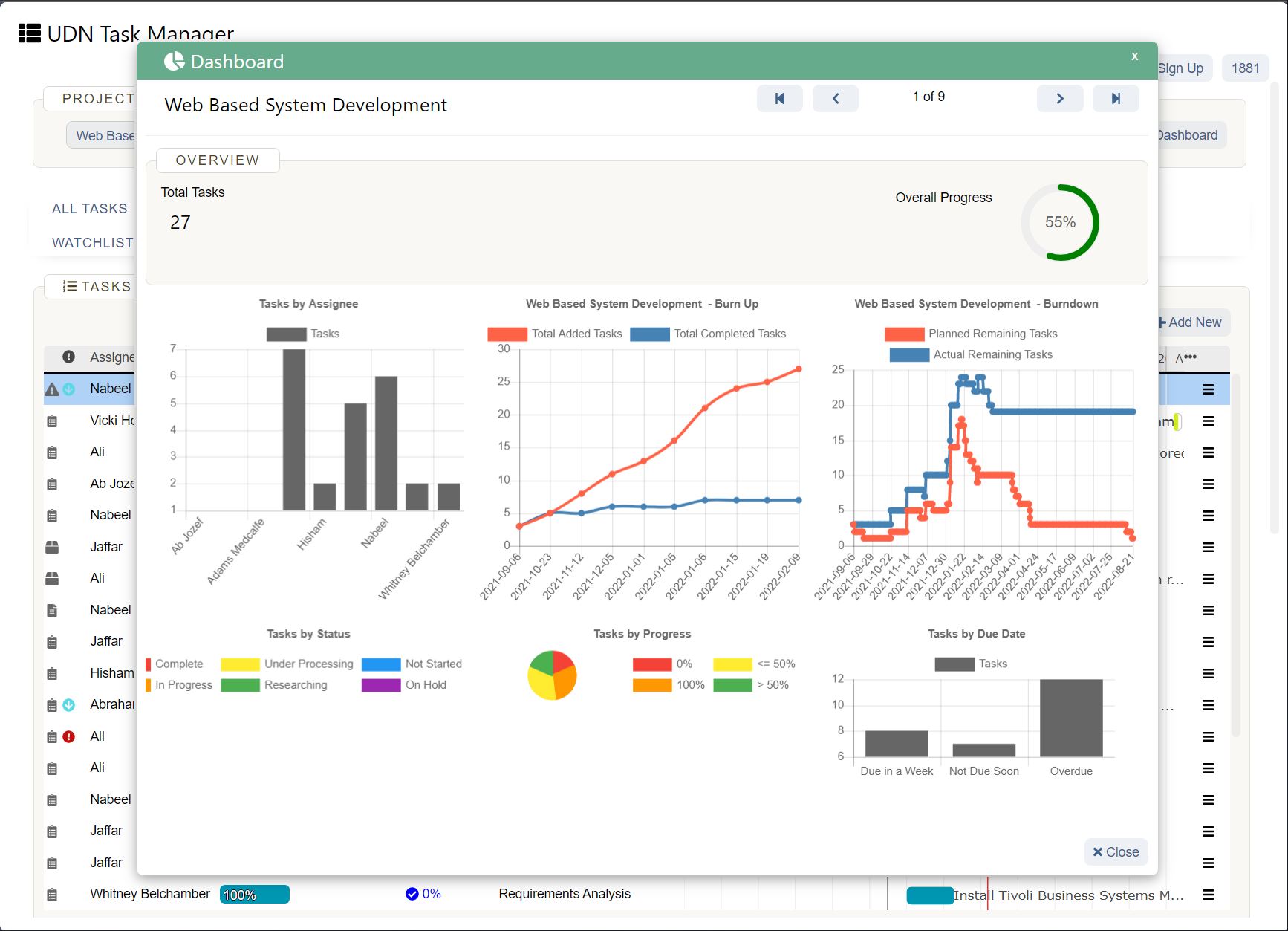

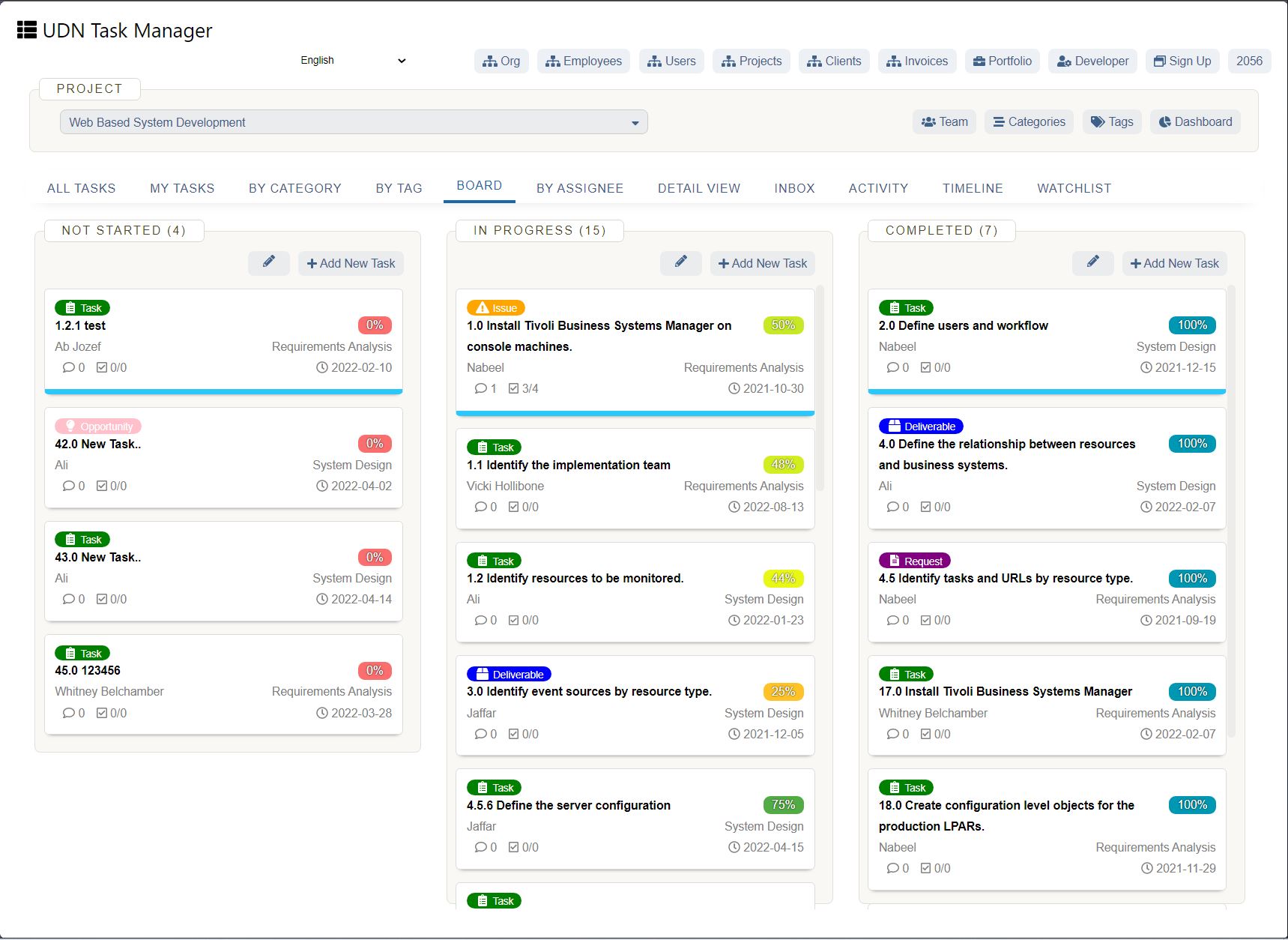

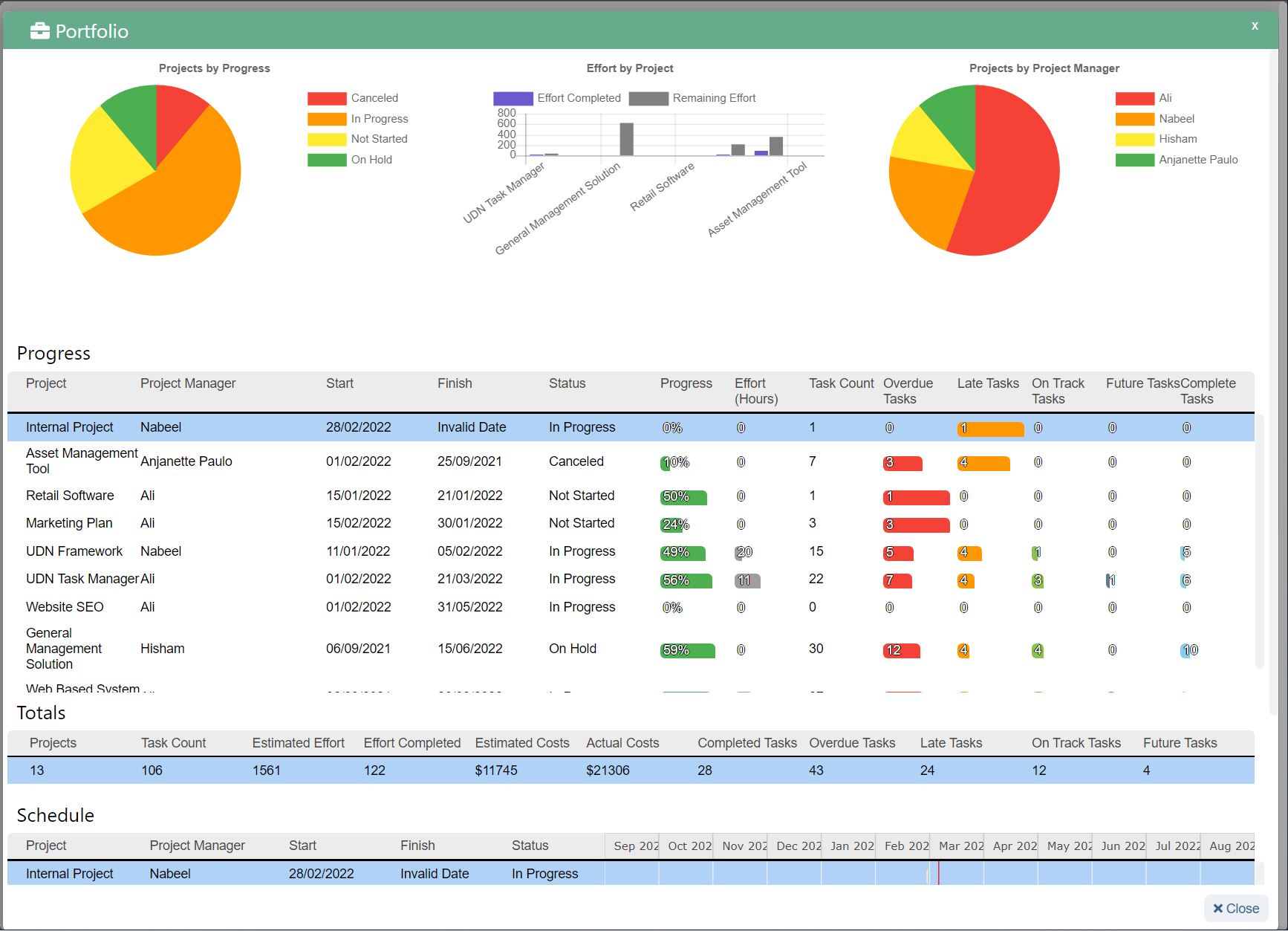

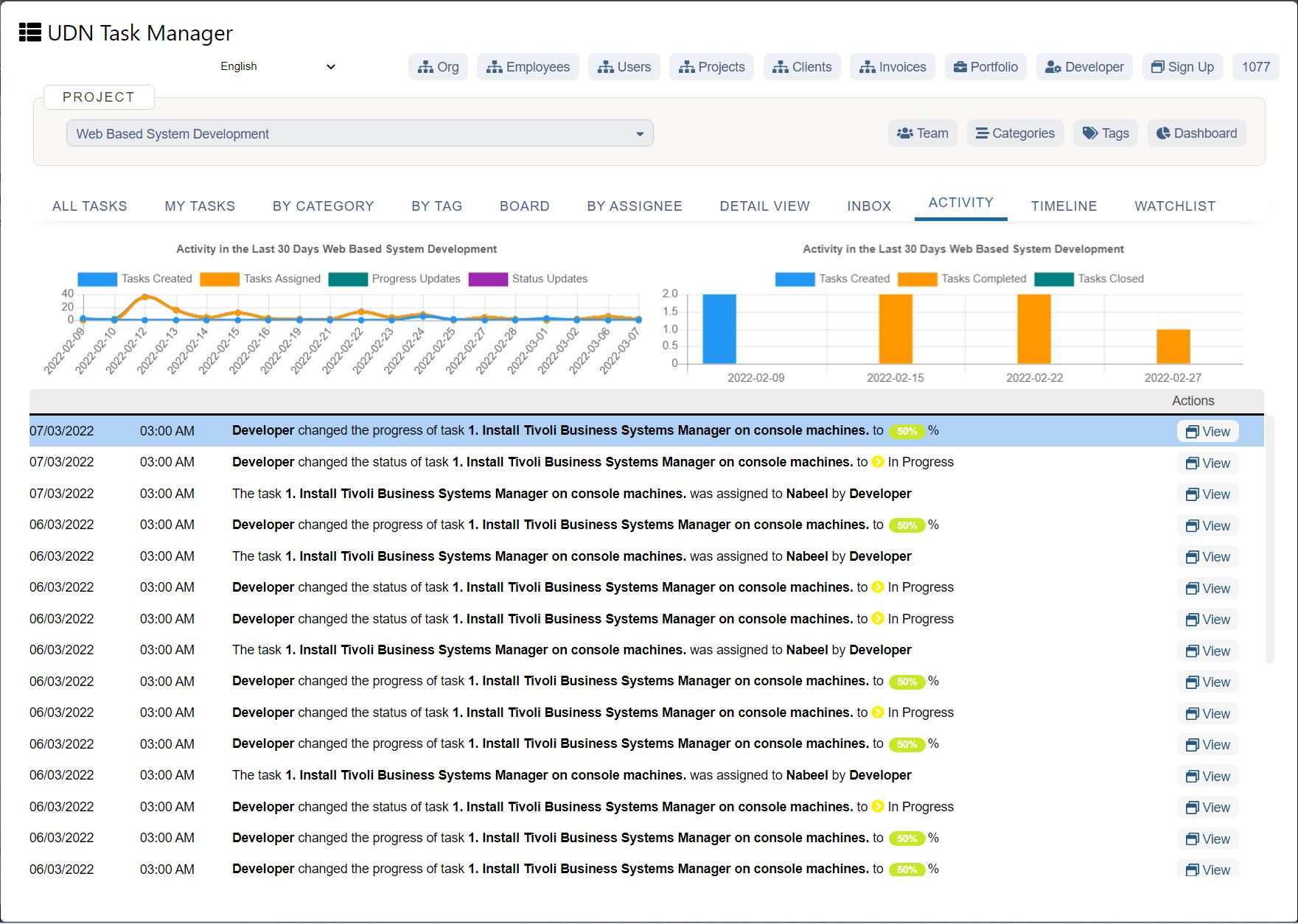

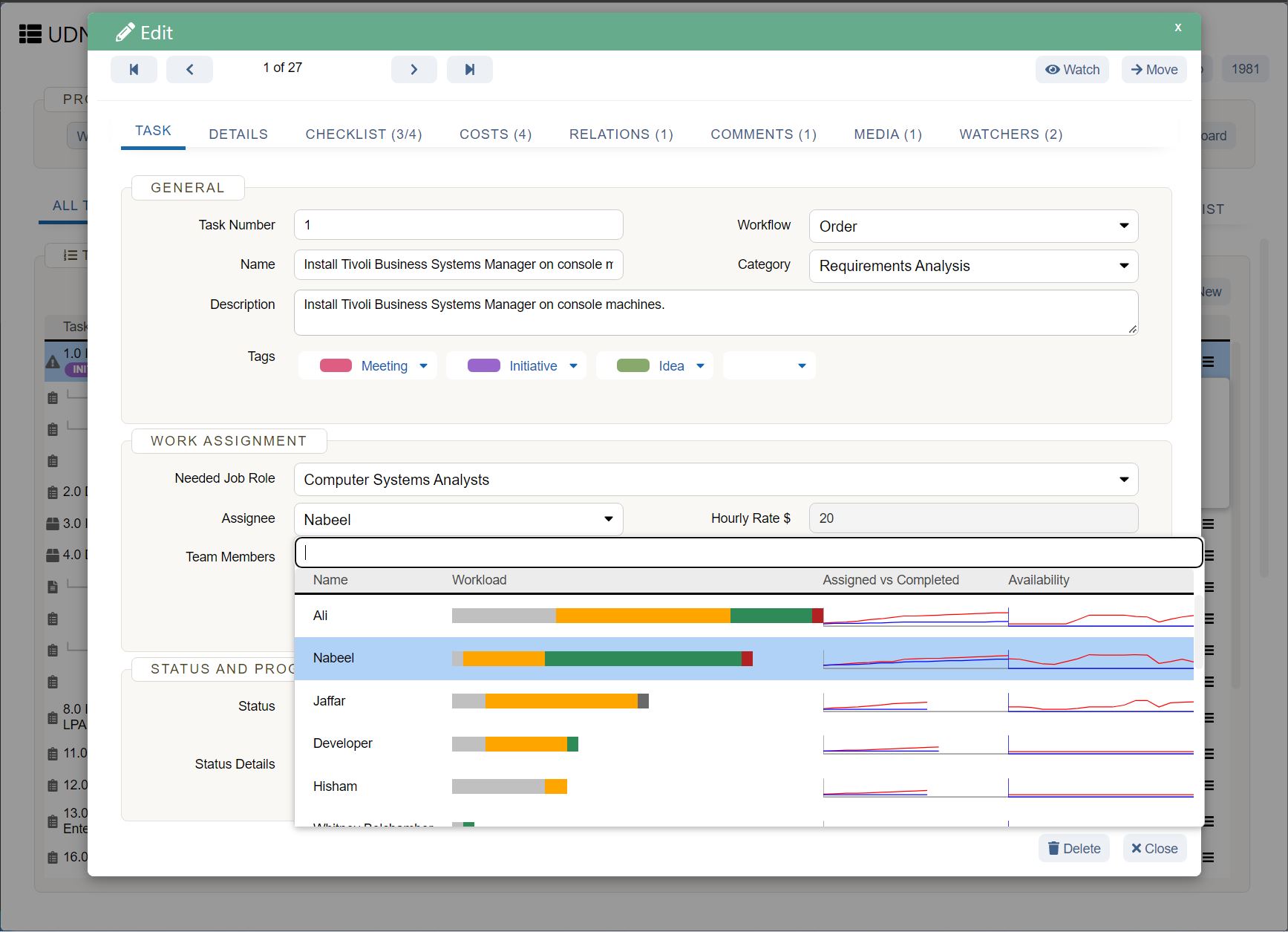

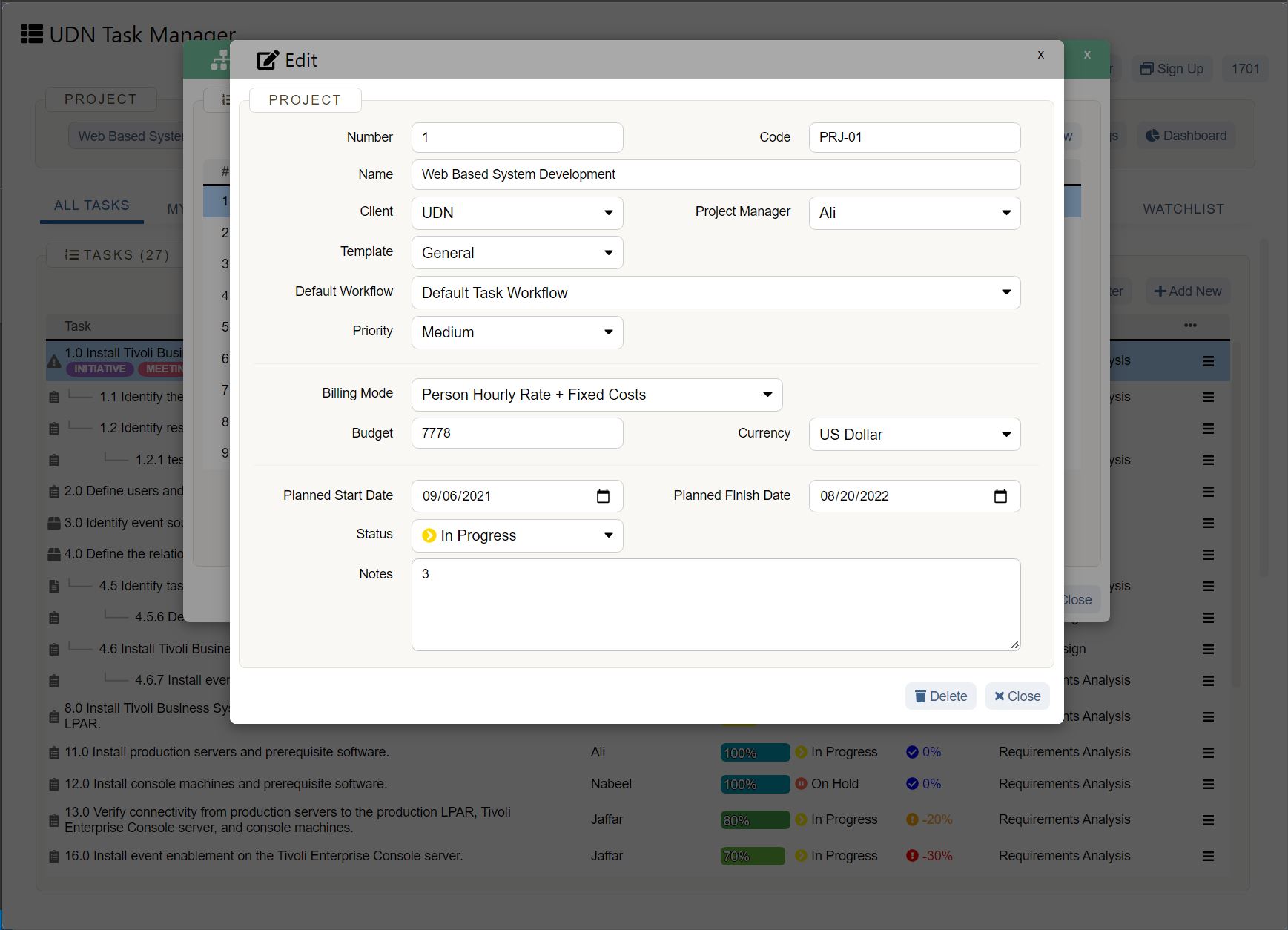

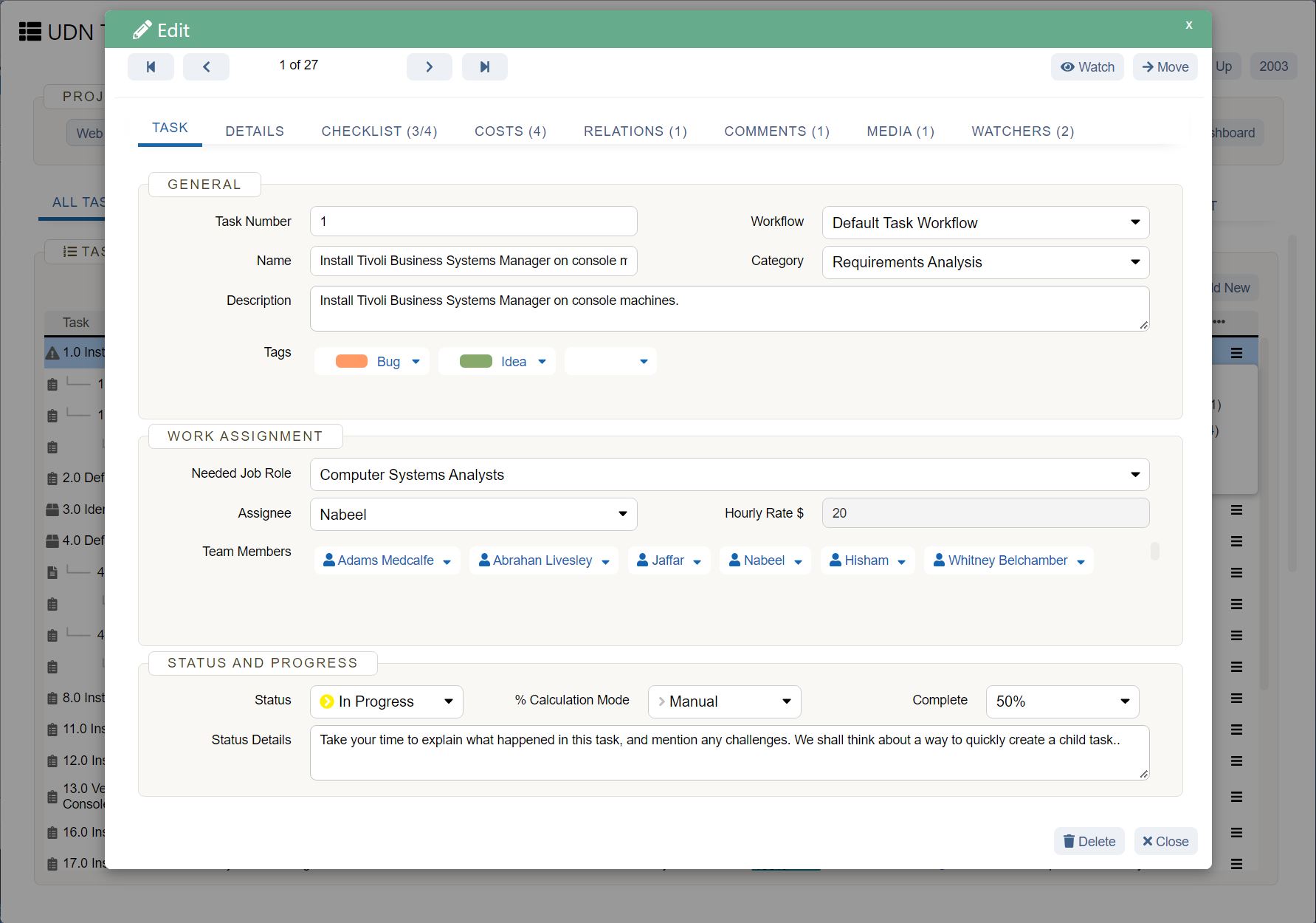

Track and improve workflows using UDN Task Manager

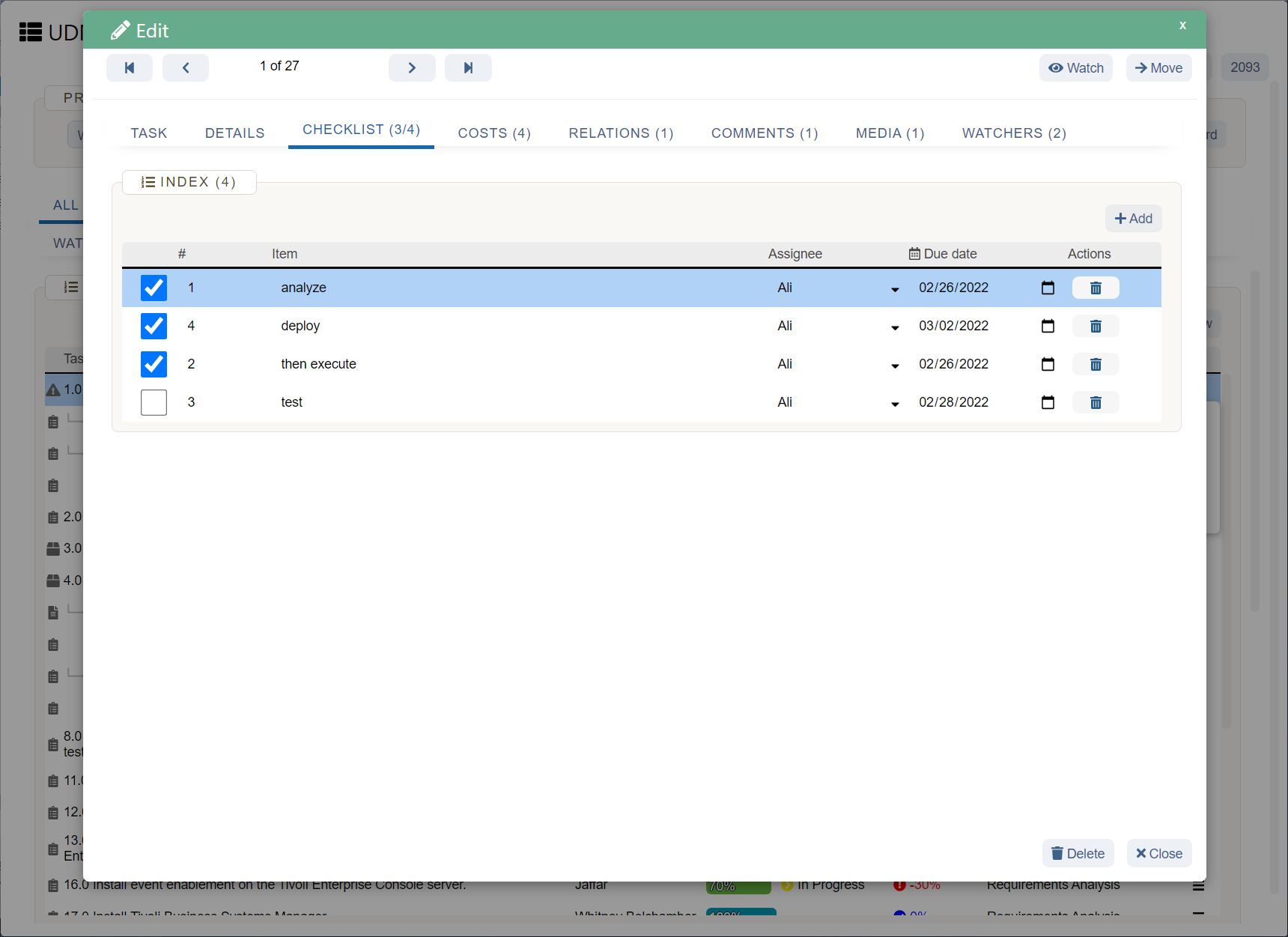

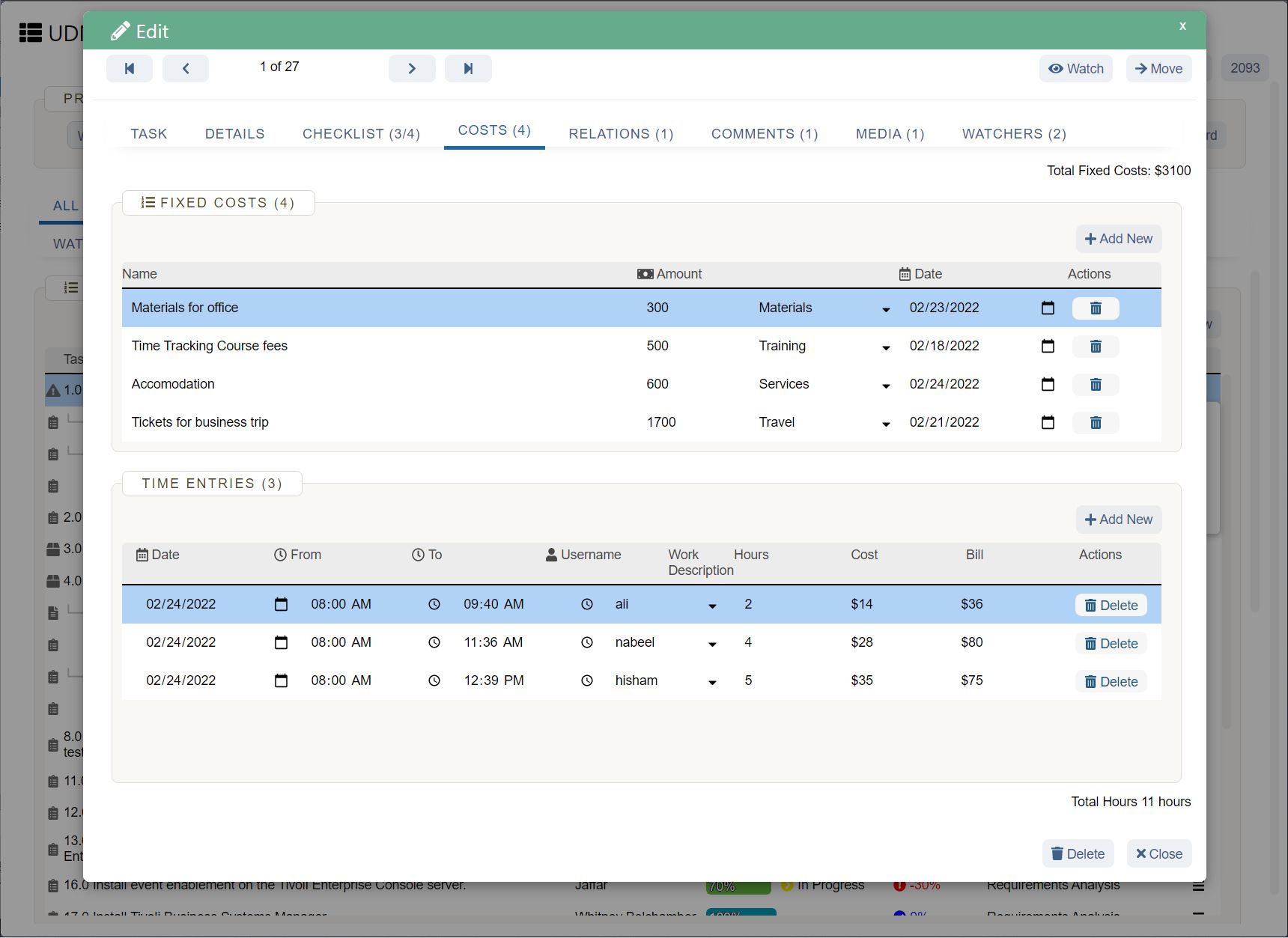

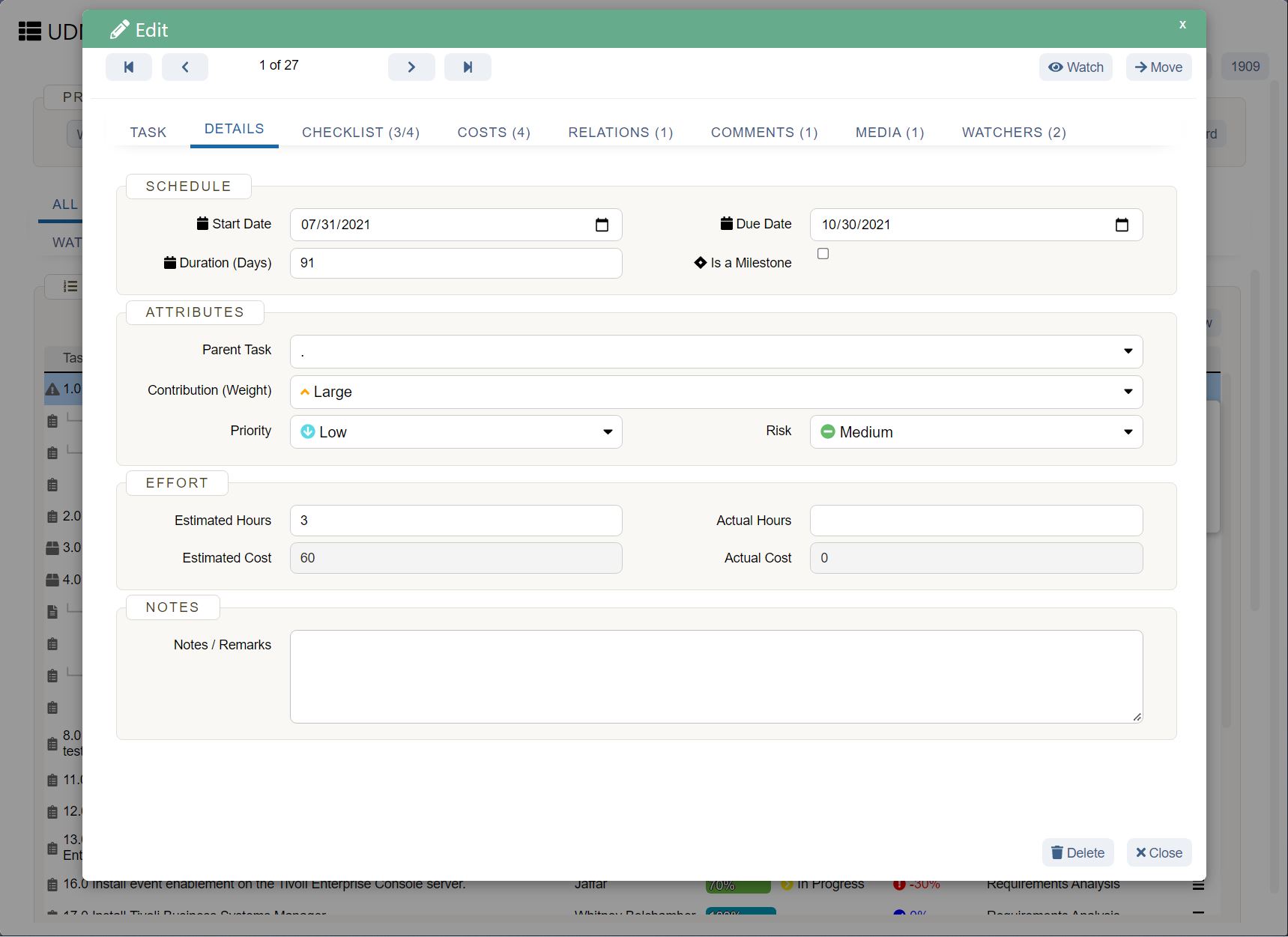

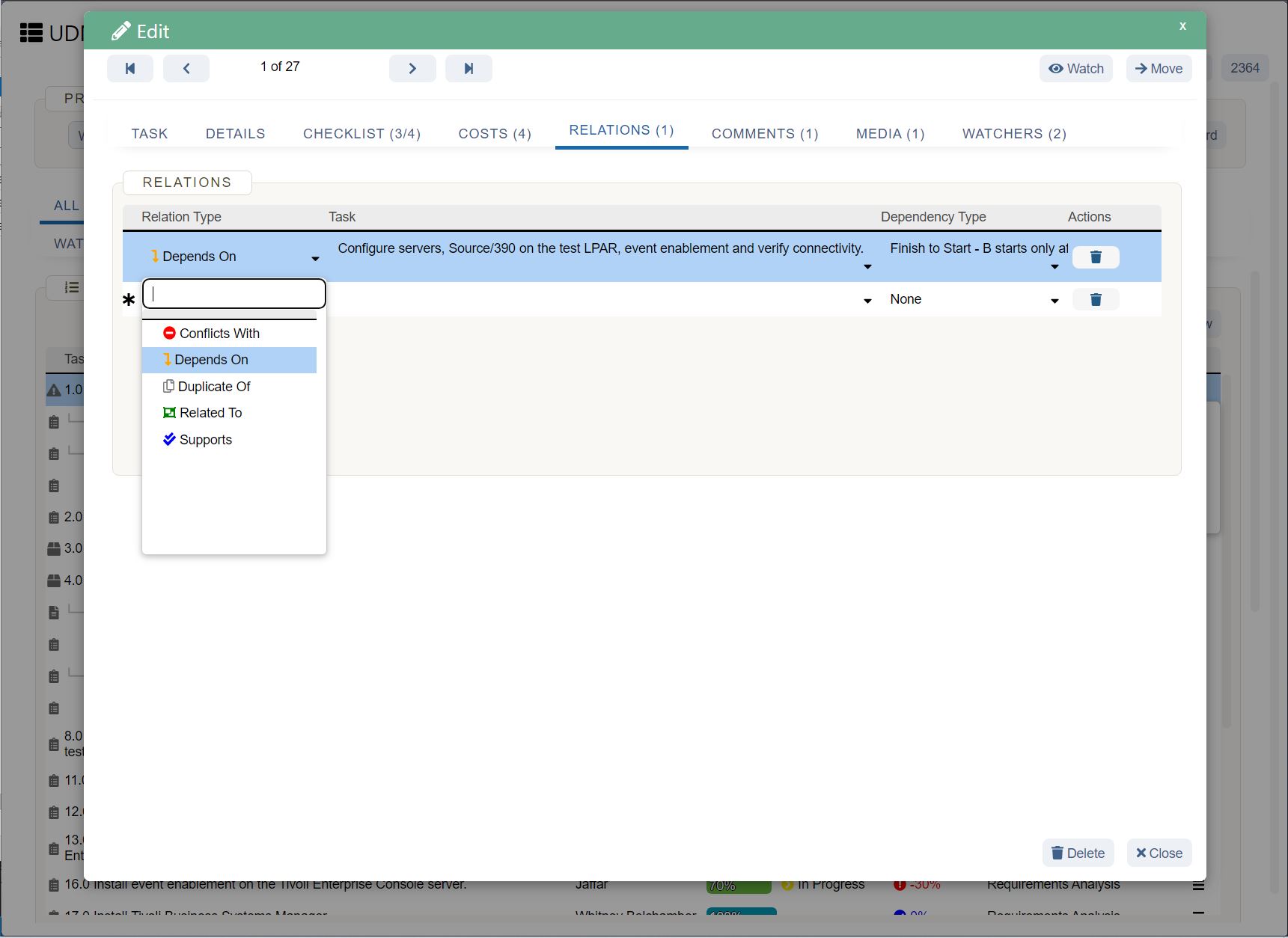

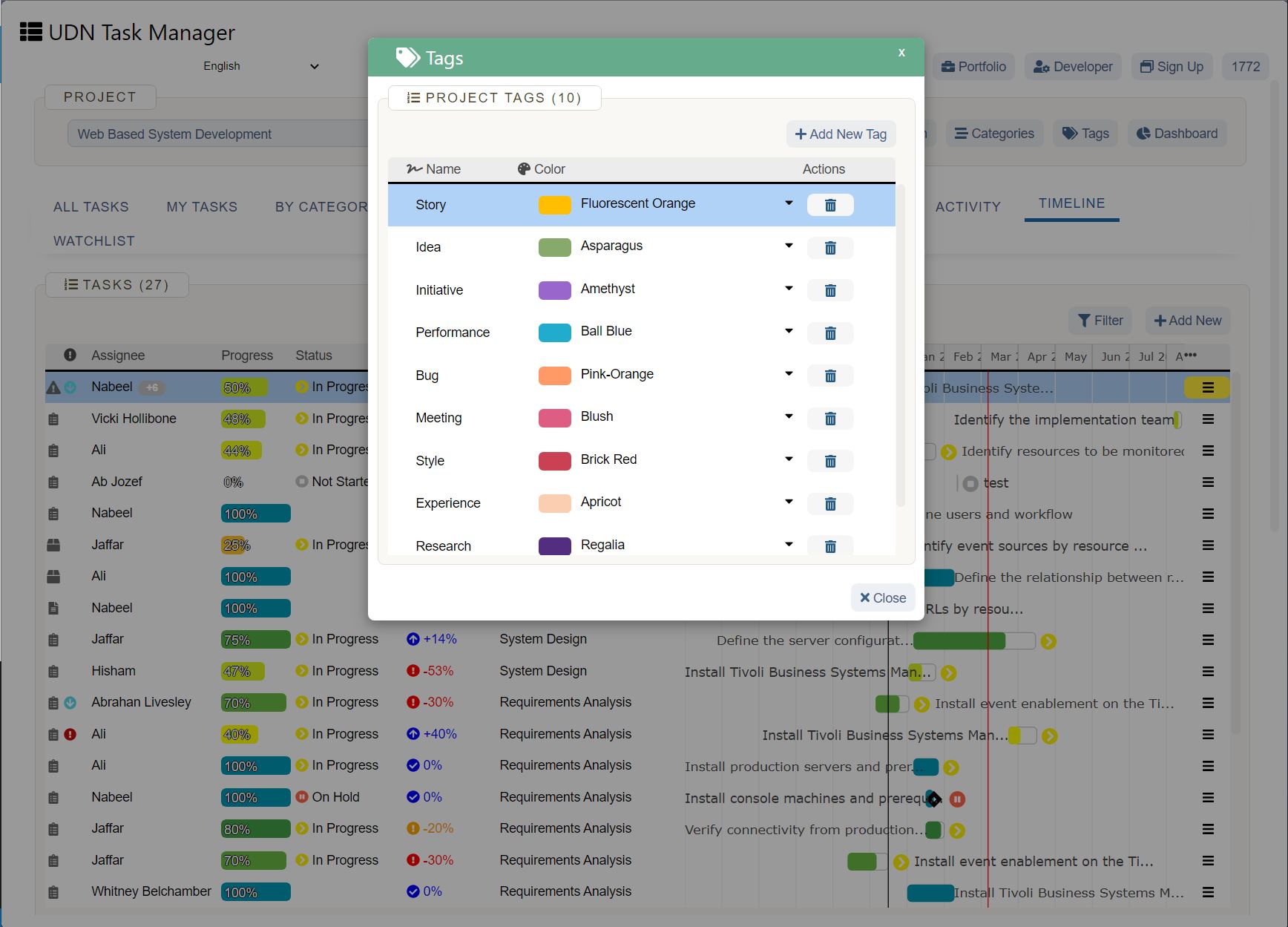

When brainstorming and analyzing workflows, it’s best to use a visual platform like UDN Task Manager . Using the Timeline feature in UDN Task Manager can help you visualize each step in your production process and assign them to specific owners.

If you’re looking to improve your team’s workflows, it’s best to use software that helps connect your team and manage goals. UDN Task Manager workflows can help you manage and automate how work is completed. Plus, you can easily alert other team members of workflow changes, make real-time adjustments, and create a single source of truth for your entire team.